Underground diaphragm wall construction method suitable for pebble and boulder stratums with non-uniform hardness

A kind of underground diaphragm wall, uneven soft and hard technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problem of serious intrusion limit of underground diaphragm wall, failure to meet the requirements of construction period, accuracy can not be guaranteed and other problems , to achieve the effect of reducing construction cost, improving construction speed and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

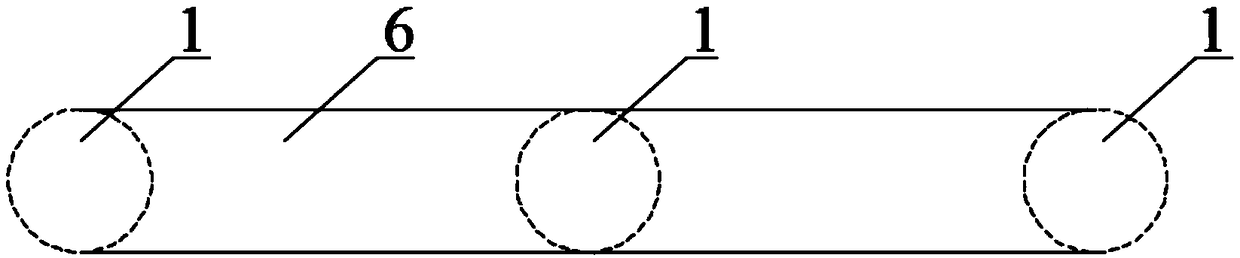

[0028] see Figure 1-2 The invention relates to a construction method for an underground diaphragm wall suitable for soft and hard uneven boulder boulder formations, including 2 forming grooves in soft pebble boulder formations, drilling vertical boreholes 1, and 3 grasping soil formation in hard pebble boulder formations. The trough and underground diaphragm wall are constructed in 6 steps in four steps.

[0029] After the soft pebble boulder formation 2 is hollowed out, the grooving machine is directly used for trough forming operation, and a plurality of extended vertical boreholes 1 are drilled at the trough forming position, and the vertical boreholes 1 are drilled along the relatively hard pebble boulder. The entire depth of the diaphragm wall foundation groove 5 in the formation 3 extends.

[0030] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com