Sodium bismuth titanate piezoelectric/electrostriction lead-free ceramic material, preparation method and application thereof

A technology of sodium bismuth titanate and ceramic materials, applied in the field of piezoelectric/electrostrictive ceramics, can solve the problems of unreported piezoelectric properties, achieve high electrostrain characteristics, low energy consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a bismuth sodium titanate based piezoelectric-electrostrictive lead-free ceramic material, the chemical composition of the ceramic material is:

[0051] (1- x )(Bi 0.5 Na 0.5 )0.935 Ba 0.065 Ti 0.985 (Fe 0.5 Sb 0.5 ) 0.015 o 3 - x SrFeCo 0.5 o y ,in x =0.004.

[0052] The preparation method of bismuth sodium titanate-based piezoelectric / electrostrictive lead-free ceramic material provided in this embodiment includes the following steps:

[0053] Chemically pure or analytically pure Na 2 CO 3 、BaCO 3 , Fe 2 o 3 , Sb 2 o 3 、TiO 2 、 Bi 2 o 3 and SrFeCo 0.5 o y as raw material, weighed by stoichiometric ratio (assuming that the synthesis final product of this embodiment is 0.2mol, then the number of moles of each raw material required is respectively Na 2 CO 3 / BaCO 3 / Fe 2 o 3 / Sb 2 o 3 / TiO 2 / Bi 2 o 3 / SrFeCo 0.5 o y = 0.046563 / 0.012948 / 0.000747 / 0.000747 / 0.196212 / 0.046563 / 0.008; the calculation and...

Embodiment 2

[0057] This embodiment provides a bismuth sodium titanate based piezoelectric / electrostrictive lead-free ceramic material, the chemical composition of the ceramic material is:

[0058] (1- x )(Bi 0.5 Na 0.5 ) 0.935 Ba 0.065 Ti 0.985 (Fe 0.5 Sb 0.5 ) 0.015 o 3 - x SrFeCo 0.5 o y ,in x =0.008.

[0059] Chemically pure or analytically pure Na 2 CO 3 、BaCO 3 , Fe 2 o 3 , Sb 2 o 3 、TiO 2 、 Bi 2 o 3 and SrFeCo 0.5 o y As raw material, weighed according to the stoichiometric ratio, batched according to the conventional solid-phase synthesis method, mixed by ball milling for 8 hours, dried, shaped, sintered at 1050°C for 3 hours, and formed bismuth sodium titanate-based piezoelectric / electrostrictive lead-free ceramic materials .

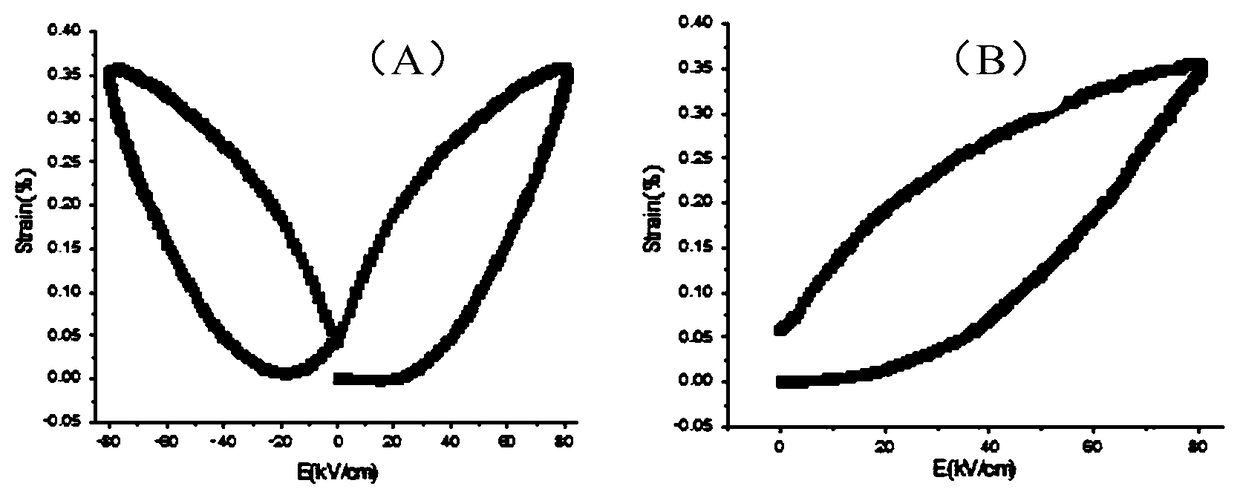

[0060] The obtained bismuth-sodium titanate-based piezoelectric / electrostrictive lead-free ceramic material is cleaned by a silver electrode after ultrasonic cleaning. Test the electrostrictive coefficient of fresh samples at room...

Embodiment 3

[0063] This embodiment provides a bismuth sodium titanate based piezoelectric / electrostrictive lead-free ceramic material, the chemical composition of the ceramic material is:

[0064] (1- x )(Bi 0.5 Na 0.5 ) 0.935 Ba 0.065 Ti 0.985 (Fe 0.5 Sb 0.5 ) 0.015 o 3 - x SrFeCo 0.5 o y ,in x =0.012.

[0065] Chemically pure or analytically pure Na 2 CO 3 、BaCO 3 , Fe 2 o 3 , Sb 2 o 3 、TiO 2 、 Bi 2 o 3 and SrFeCo 0.5 o y As raw material, weighed according to the stoichiometric ratio, batched according to the conventional solid-phase synthesis method, mixed by ball milling for 8 hours, dried, shaped, sintered at 1050°C for 3 hours, and formed bismuth sodium titanate-based piezoelectric / electrostrictive lead-free ceramic materials .

[0066] The obtained bismuth-sodium titanate-based piezoelectric / electrostrictive lead-free ceramic material is cleaned by a silver electrode after ultrasonic cleaning. Test the electrostrictive coefficient of fresh samples at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric constant | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com