Ship body outer surface rope traction parallel spraying robot

A technology for spraying robots and outer surfaces, which is applied in the direction of manipulators, spraying devices, program-controlled manipulators, etc., and can solve problems such as vacuum power failure, serious physical injury of workers, and danger of workers working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

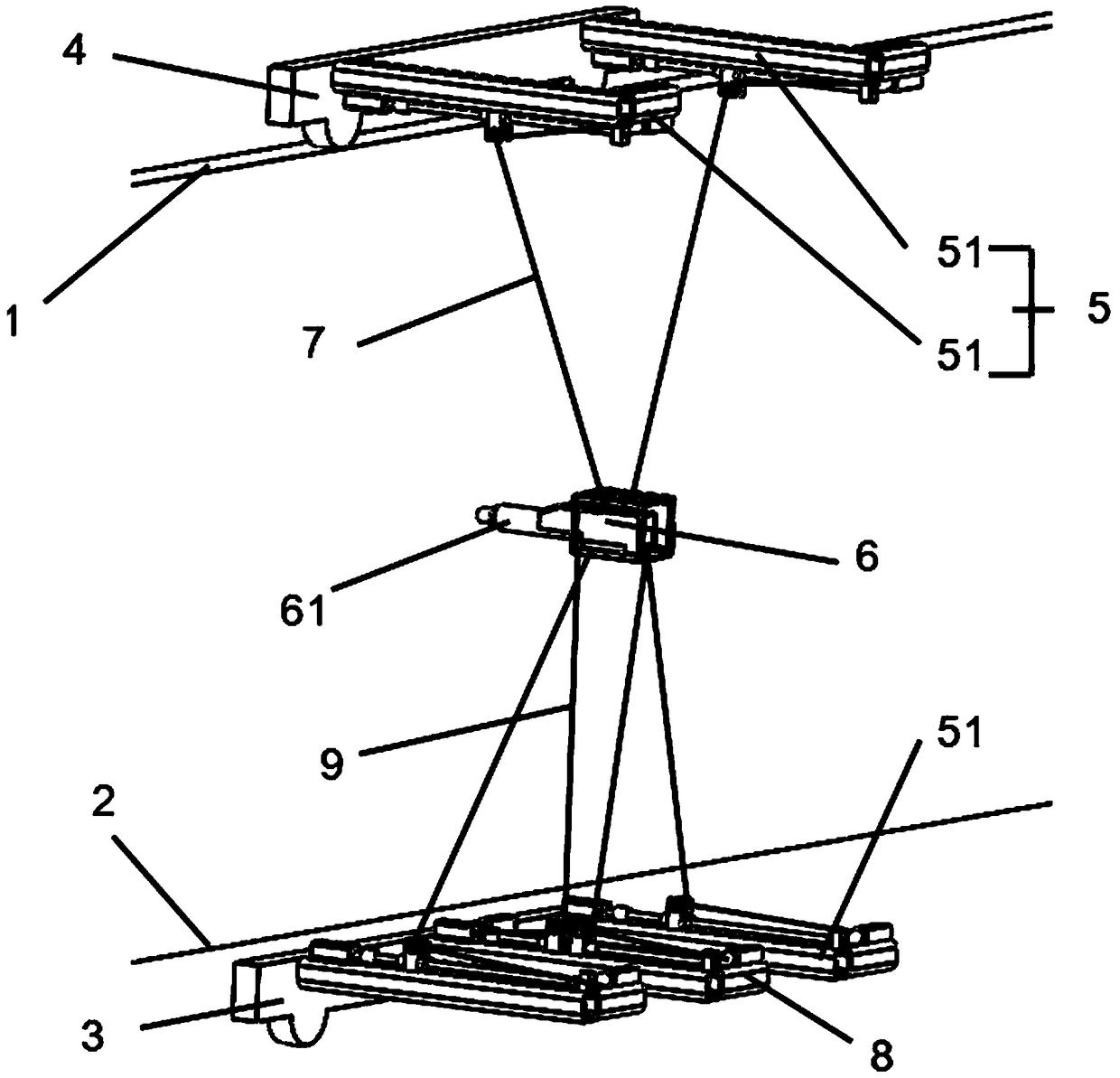

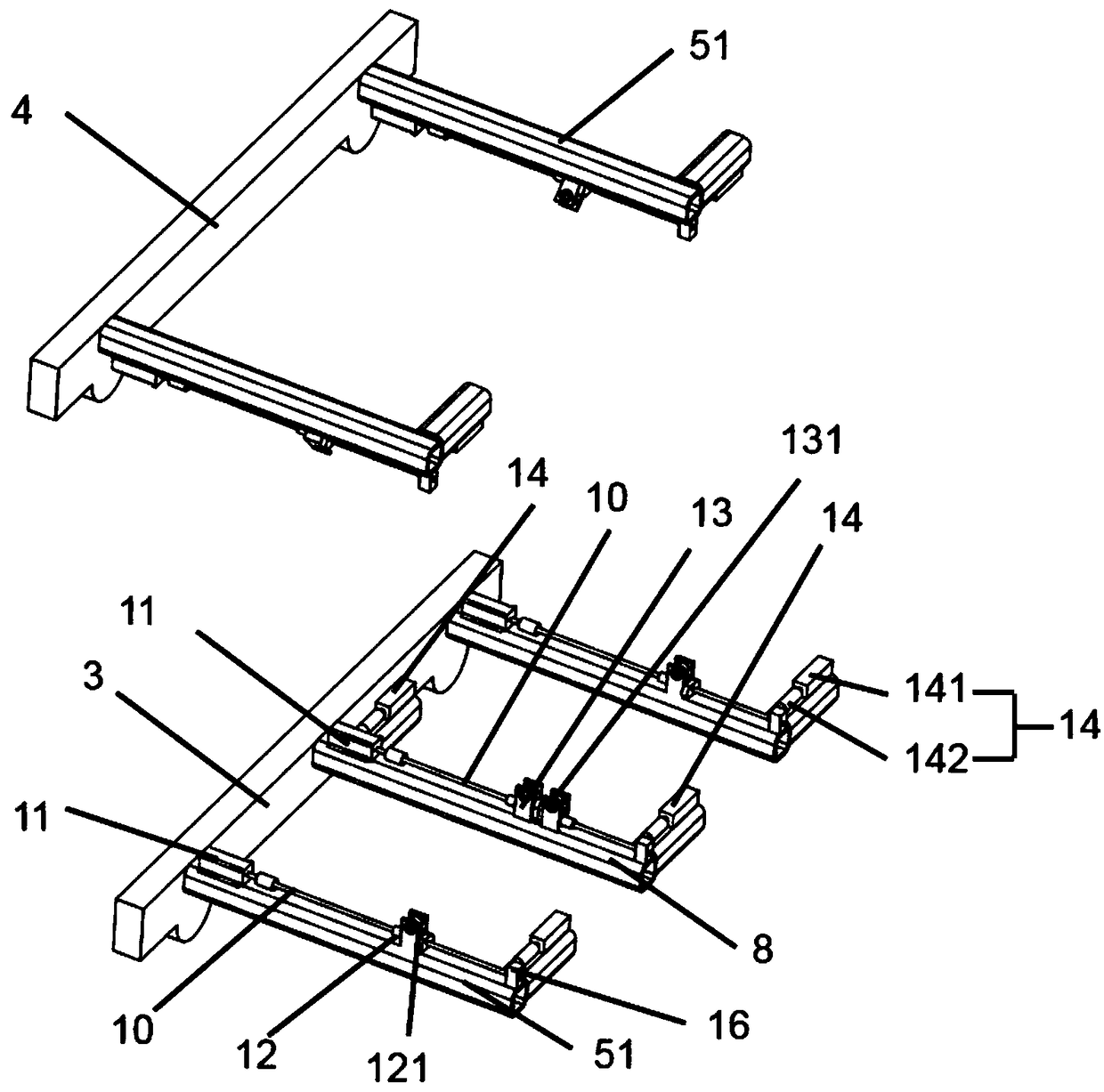

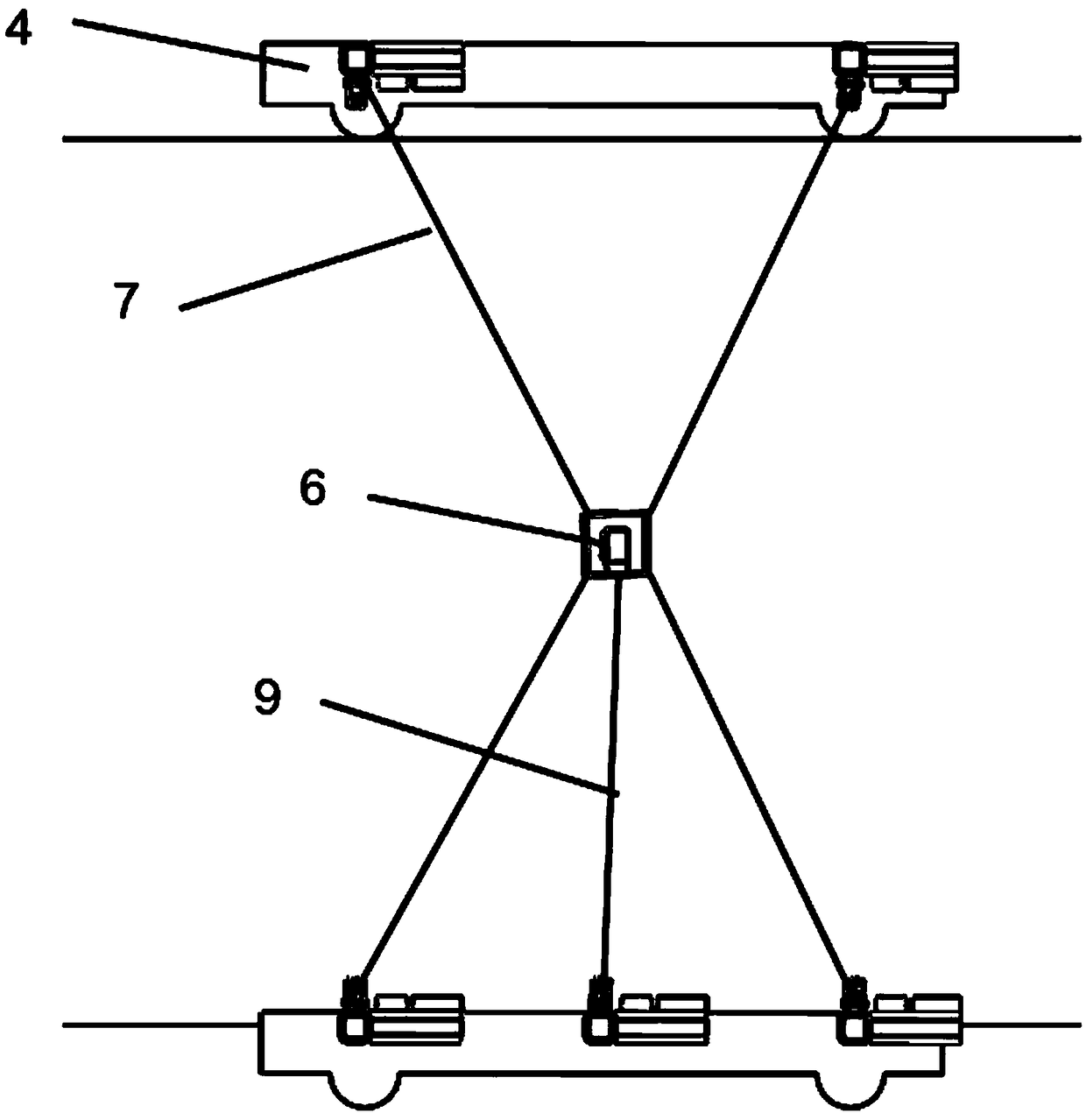

[0022] Such as figure 1 and figure 2 As shown, a rope traction parallel spraying robot on the outer surface of the hull includes two upper guide rails 1 and lower guide rails 2 oppositely arranged on the side of the hull. The base 4, the lower base 3 and the upper base 4 are all provided with 5 sets of support frames along the direction perpendicular to the extension of the lower guide rail 2. The 5 sets of support frames include two parallel support rods 51, and the support rods 51 are provided with distance-adjustable slideways. And the first slider 12 that is slidably arranged on the distance-adjusting slideway; the first slider 12 is horizontally provided with a first roller 121, and the axis direction of the first roller 121 is perpendicular to the length direction of the support rod 51. On the first roller 121 A rope 7 is sheathed, and one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com