Battery core sorting machine

A sorting machine and cell technology, applied in the field of sorting machines, can solve the problems of complex structure of cell sorting machine, affecting cell detection speed, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

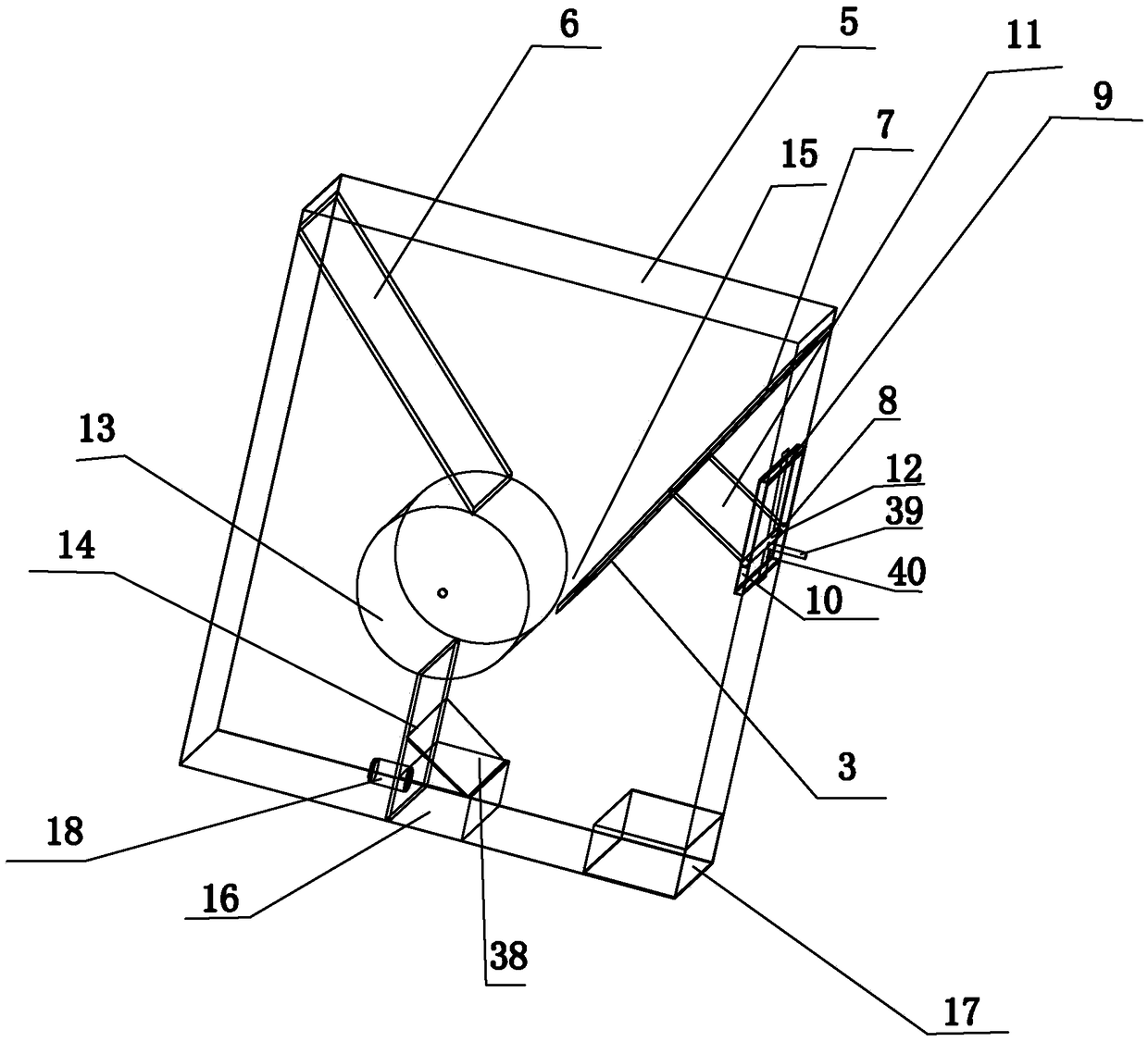

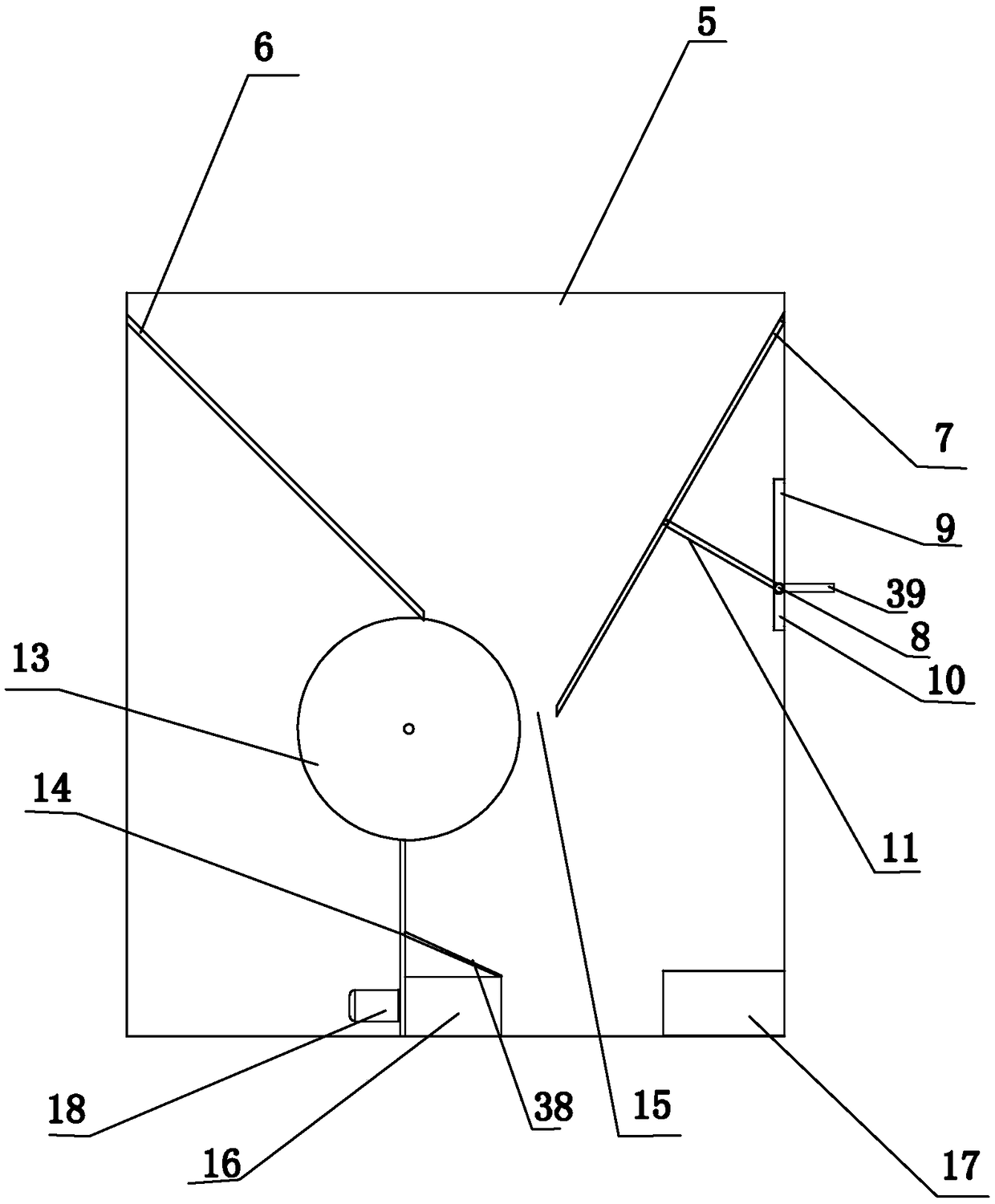

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as Figure 1-10 shown;

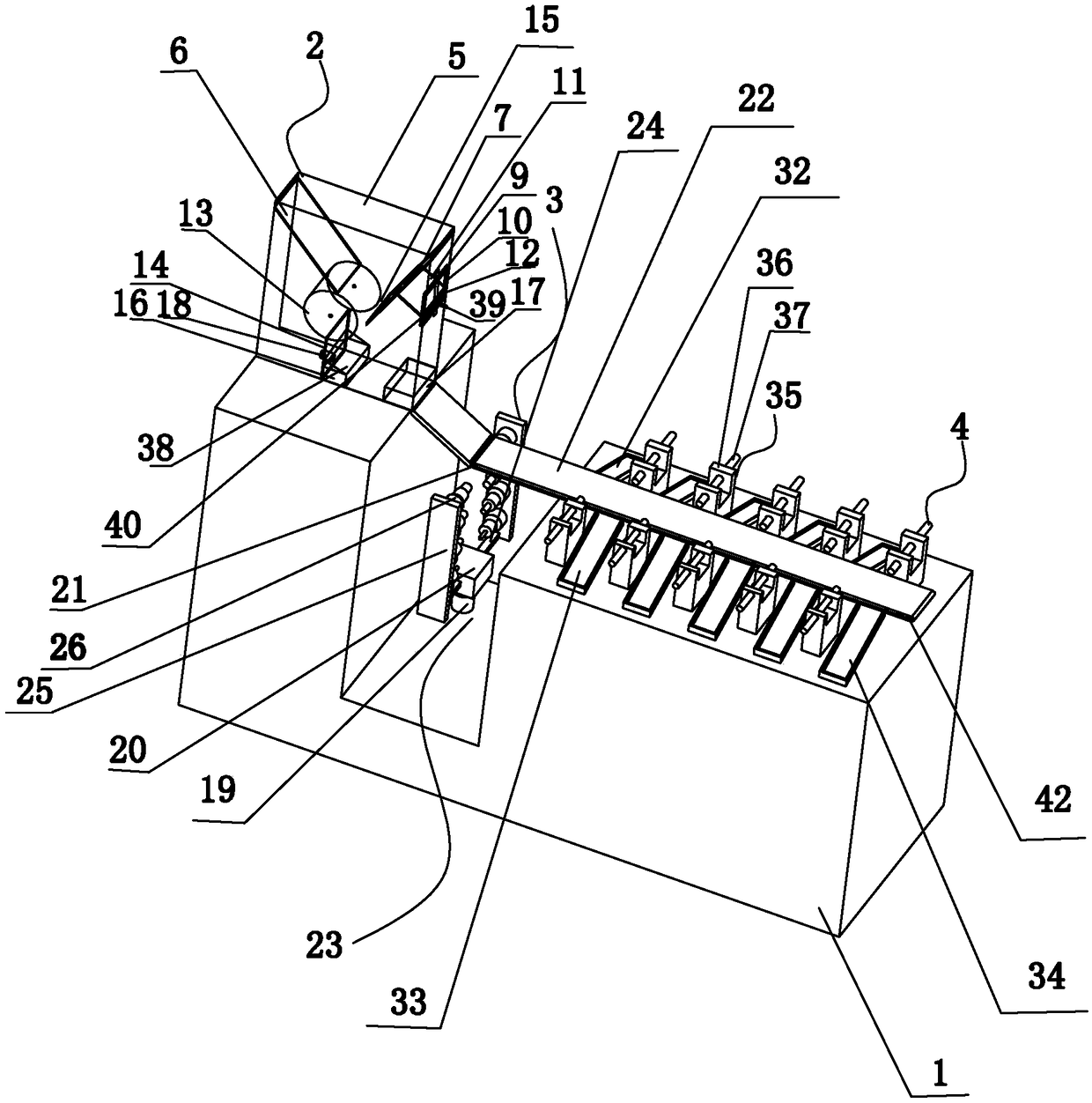

[0031] A cell sorting machine of the present invention comprises a frame 1, a feeding module 2, a testing module 3, and a sorting module 4;

[0032] In this embodiment, there can be a total controller (not shown in the figure) electrically connected with the feeding module 2, the testing module 3 and the sorting module 4, for controlling, for example: the first driving motor 18 and the linear stepping motion of the second drive motor, the rotation of the material runner 13, the operation of the conveyor belt 22, the propelling action of the propulsion unit 35, etc.; in addition the lifting cylinder 19 is driven by a pneumatic control system (not shown in the figure) .

[0033] The feed module 2 includes a feed bin 5 with an open upper end, and the feed bin 5 is provided with a first material gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com