Shock absorption base for building engineering equipment

A technology for construction engineering and equipment, applied in shock absorbers, mechanical equipment, springs/shock absorbers, etc. Stable and reliable effect, improved applicability, and efficient shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

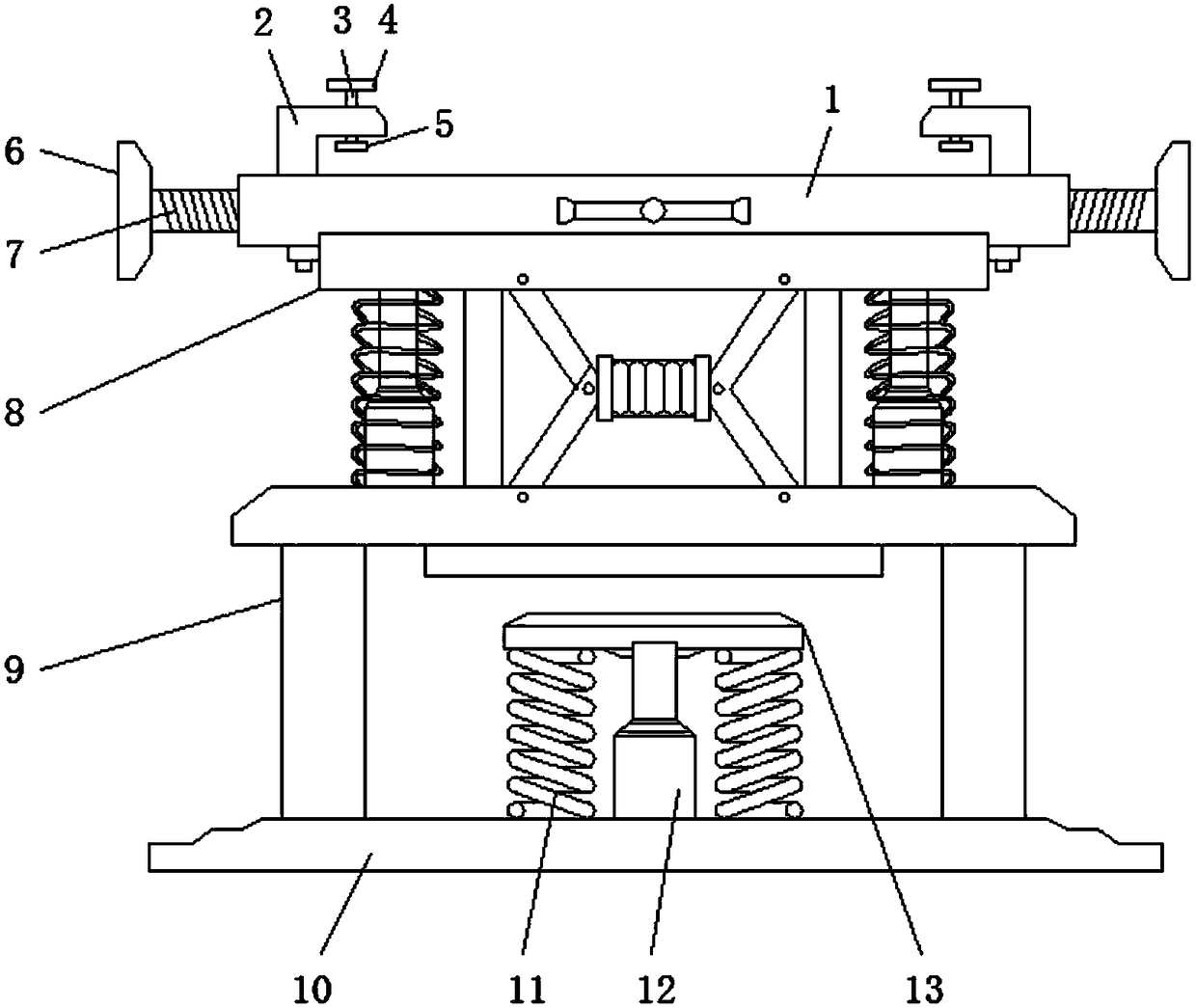

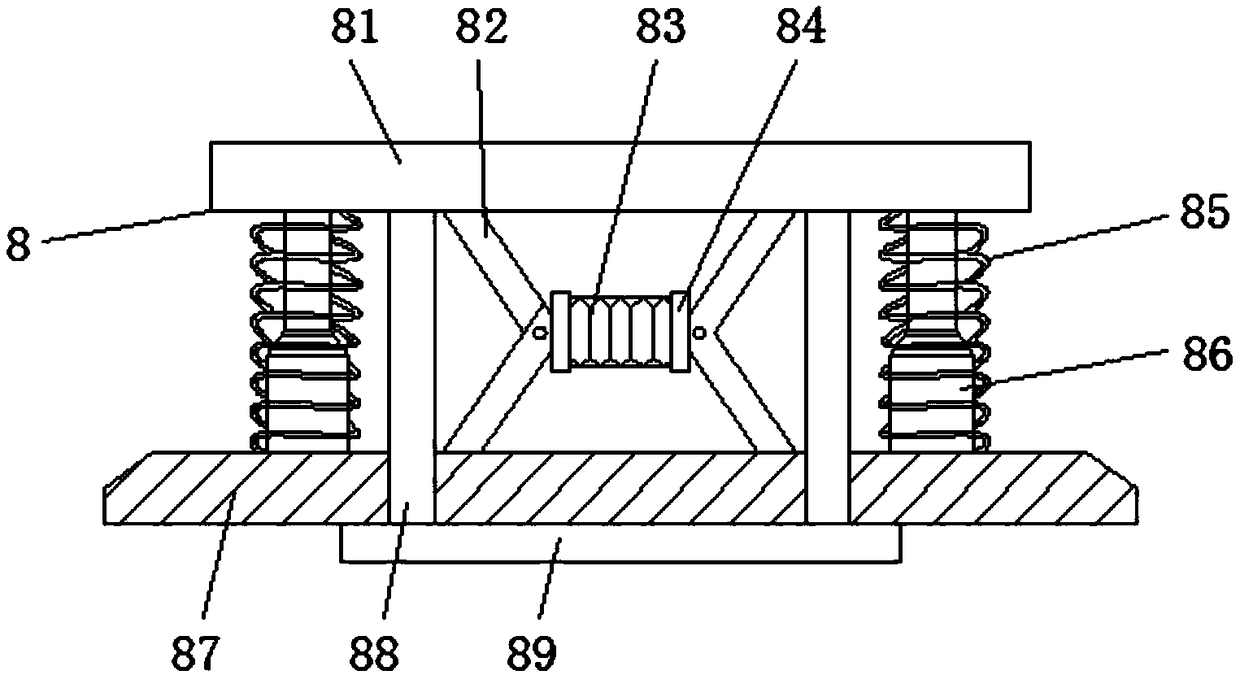

[0025] Embodiment one, with reference to Figure 1-2 , a shock absorbing base for construction engineering equipment, comprising a base plate 1, characterized in that the bottom of the base plate 1 is fixedly connected with a shock absorbing mechanism 8, and the shock absorbing mechanism 8 is composed of a top plate 81, a connecting rod 82, an air spring 83, and a connecting block 84 , the first damping spring 85, the first hydraulic telescopic rod 86, the bottom plate 87, the pole 88 and the upper contact plate 89 are combined, the two ends of the air spring 83 are connected with the connecting block 84, and the upper and lower ends of the connecting block 84 They are respectively hinged with the top plate 81 and the bottom plate 87 through connecting rods 82, and the bottom sides of the top plate 81 are connected with the top sides of the bottom plate 87 through symmetrically arranged first hydraulic telescopic rods 86, and the outer sides of the first hydraulic telescopic ro...

Embodiment 2

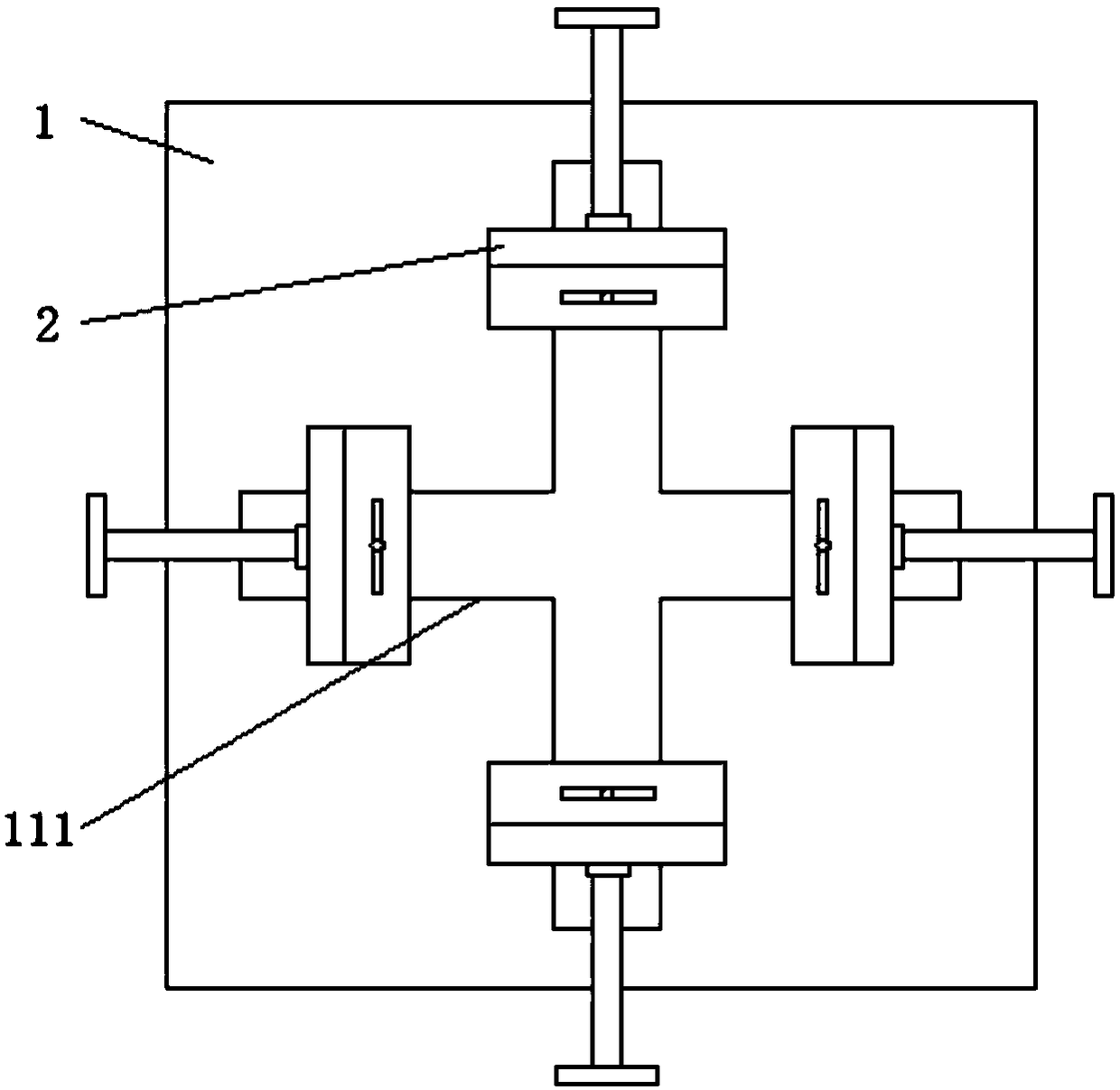

[0026] Embodiment two, refer to figure 1 with image 3 , the inside of the substrate 1 is provided with a convex chute 111 in a cross shape, and the inside of the convex chute 111 is slidably connected with a convex slider 14, and the center of one side of the convex slider 14 is movably connected with a second fixed bearing. Threaded rod 7, and the second threaded rod 7 runs through one side of the substrate 1 and is welded with the second screw rod 6. The top of the convex chute 111 is welded with an L-shaped clamping plate 2, and the convex shape is made by rotating the second screw rod 6. The slider 14 slides inside the convex chute 111, and the convex slider 14 drives the L-shaped clamping plate 2 to limit the side of the connection seat of the construction equipment, thereby satisfying the installation and use of construction equipment of different sizes.

Embodiment 3

[0027] Embodiment three, refer to figure 1 The horizontal end of the L-shaped clamp 2 is vertically screwed and connected with the first threaded rod 3, the top of the first threaded rod 3 is welded with the first screw 4, and the bottom end is welded with the lower side of the horizontal end of the L-shaped clamp 2. The spacer 5 rotates the first screw rod 4 and the first threaded rod 3 rotates, so that the spacer 5 goes down, and finally limits the top of the construction equipment connection seat, so that the fixing effect is more stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com