Electrodes for resistance welding

A resistance welding and electrode technology, applied in resistance welding equipment, electrode characteristics, welding equipment, etc., can solve the problems of wasting compressed air, high maintenance cost, not so economical, etc., and achieve the effect of reducing gas consumption and reducing the possibility of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

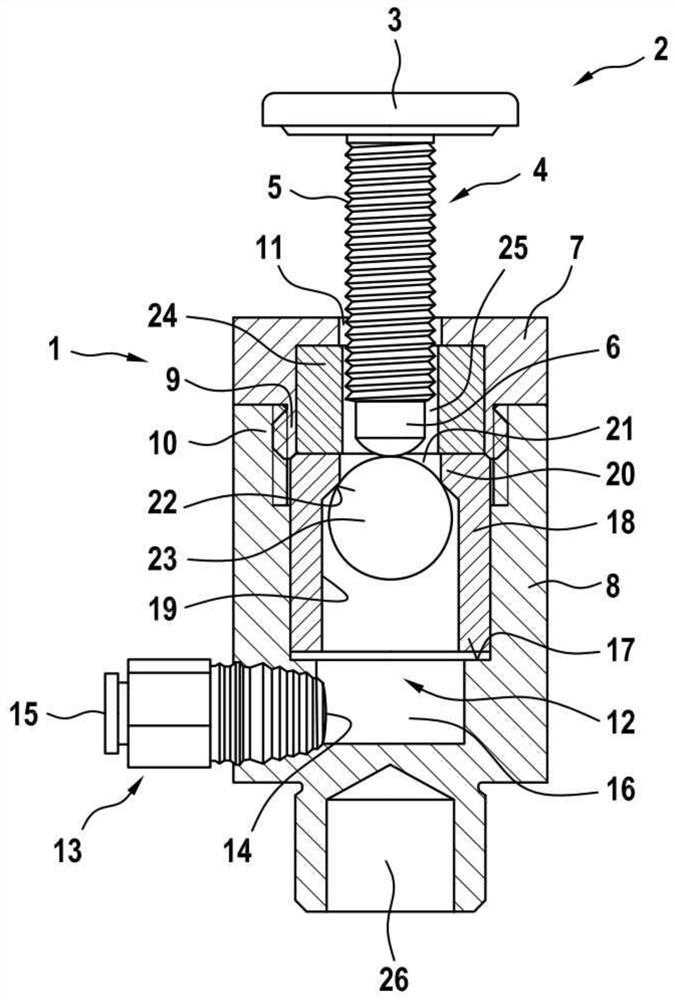

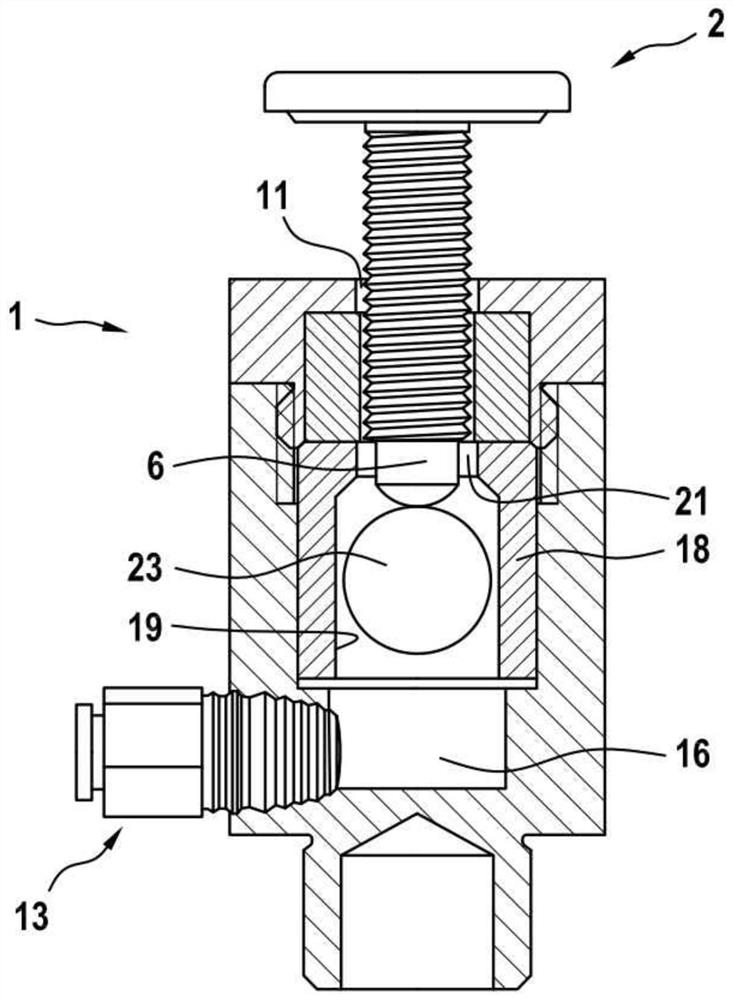

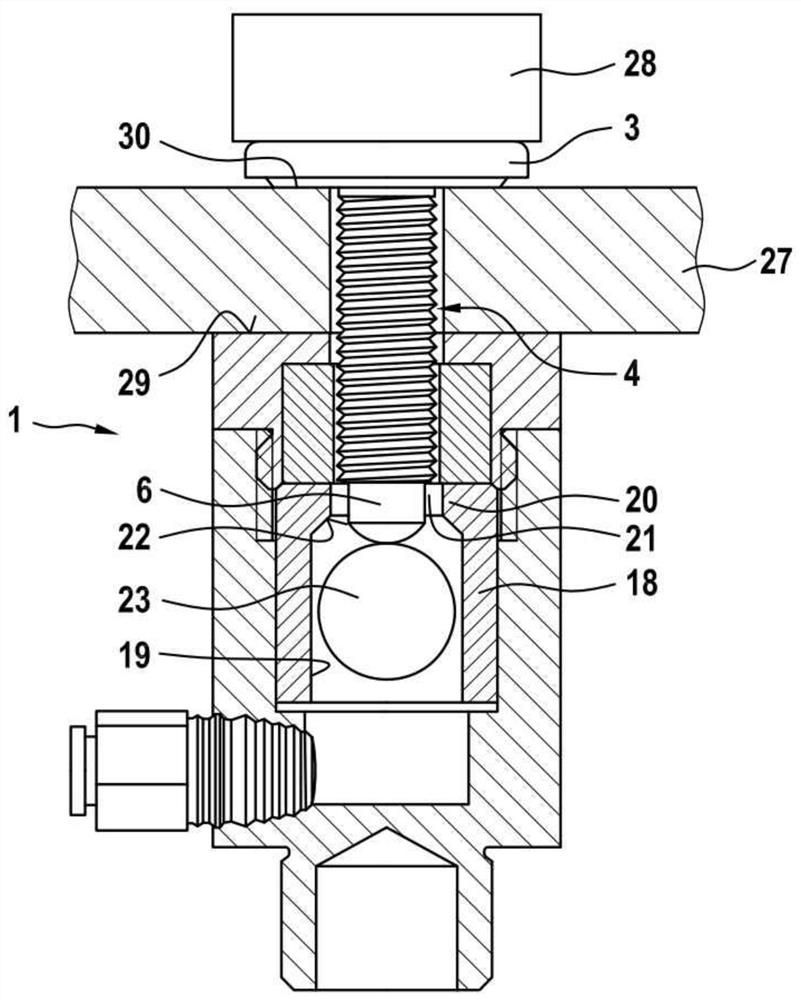

[0051] figure 1 An exemplary embodiment of an electrode 1 according to the invention is shown in a schematic sectional view. It should be pointed out that in the following description of the figures, components having the same or similar function are provided with the same reference symbols for reasons of clarity, even if the components deviate from one another in detail. Positional specifications such as "above", "below", "sideways" or "rearward" relate to the upright electrode 1 as it is used and depicted in resistance welding.

[0052] Shown are electrode 1 and plug 2 . The bolt 2 is currently designed as a bolt. The bolt has a bolt head 3 and a bolt shank 4 which is directly connected to the bolt head 3 .

[0053] The bolt shank 4 has a thread 5 . The thread 5 is formed as an external thread. Furthermore, the screw shank 4 has a free end 6 . The free end 6 is tapered on the end side. Bolts are currently made of metal, especially steel.

[0054] The electrode 1 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com