Method for preparing gold-platinum core-shell nanostructural material

A nanostructure and gold preparation technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of precise control of Pt deposition position without complex structure gold nanoparticles and other issues to achieve the effects of high-efficiency catalytic performance, simple process, good catalytic performance and SERS performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

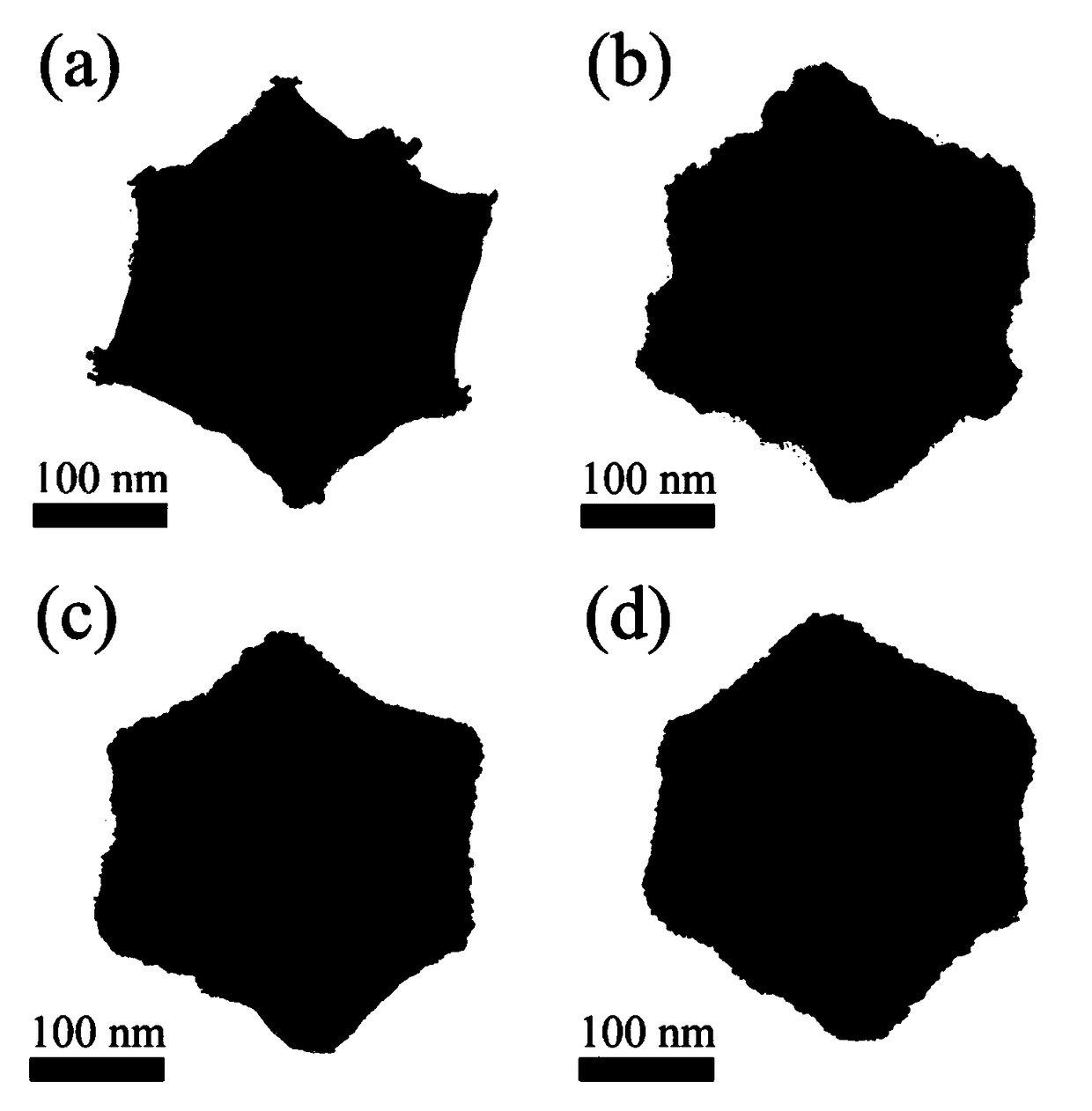

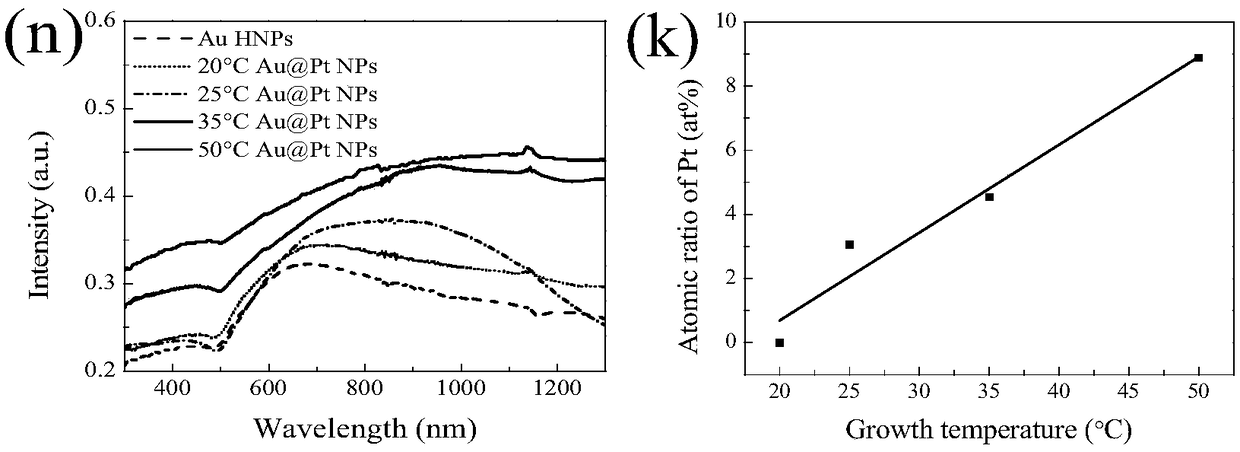

[0019] Based on temperature control, the in-situ reduction on the surface of hexahedral gold nanoparticles and the precise deposition of Pt on the sharp corners form a gold-platinum core-shell nanostructure covered with Pt on the sharp corners. The following steps are adopted:

[0020] (1) Dilute 1 mL of hexahedral gold nanoparticle colloid into 3.5 mL of water, then add 500 μL of 200 mM CTAC aqueous solution, 10 μL of 2 mM AgNO 3 aqueous solution and 40 μL of 100 mM ascorbic acid solution, the mixture was magnetically stirred for 1.5 h at a stirring speed of 600 rpm. The whole reaction was carried out at 20°C, where mM is the abbreviation of mmol / L.

[0021] (2) Add 60μL of 10mM H 2 PtCl 6 Add the aqueous solution to step (1), maintain the reaction temperature at 20°C and continue stirring for 2h;

[0022] (3) Centrifuge and purify the product of step 2) for 3 times, the centrifugal speed is 1400, and the centrifugation time is 10 min. After purification, the precipitate ...

Embodiment 2

[0024] Based on temperature control, in situ reduction on the surface of hexahedral gold nanoparticles and precise deposition of Pt on the edges to form a gold-platinum core-shell nanostructure covered with Pt on the edges, the following steps are adopted:

[0025] (1) Dilute 1 mL of hexahedral gold nanoparticle colloid into 3.5 mL of water, then add 500 μL of 200 mM CTAC aqueous solution, 10 μL of 2 mM AgNO 3 aqueous solution and 40 μL of 100 mM ascorbic acid solution, and the mixture was magnetically stirred for 2 hours at a stirring speed of 400 rpm. The entire reaction was carried out at 25°C.

[0026] (2) Add 60μL of 10mM H 2 PtCl 6 Add the aqueous solution to step (1), maintain the reaction temperature at 25°C and continue stirring for 2h;

[0027] (3) The product of step 2) was centrifuged and purified 3 times, the centrifugal speed was 1600 rpm, and the centrifugation time was 5 min. After purification, the precipitate was redispersed in 1 mL of water, and the prod...

Embodiment 3

[0029] Based on temperature control, in situ reduction on the surface of hexahedral gold nanoparticles and precise deposition of Pt on the surface to form a gold-platinum core-shell nanostructure covered with Pt and rough on the surface, the following steps are adopted:

[0030] (1) Dilute 1 mL of hexahedral gold nanoparticle colloid into 3.5 mL of water, then add 500 μL of 200 mM CTAC aqueous solution, 10 μL of 2 mM AgNO 3 aqueous solution and 40 μL of 100 mM ascorbic acid solution, the mixture was magnetically stirred for 1.5 h at a stirring speed of 600 rpm. The entire reaction was carried out at 35°C.

[0031] (2) Add 60μL of 10mM H 2 PtCl 6 Add the aqueous solution to step (1), maintain the reaction temperature at 35°C and continue stirring for 2h;

[0032] (3) The product of step 2) was centrifuged and purified 3 times, the centrifugal speed was 1600 rpm, and the centrifugation time was 5 min. After purification, the precipitate was redispersed in 1mL of water, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com