Bubble curtain for hull-type seaplane

A seaplane and bubble curtain technology, applied in the field of bubble curtains, can solve the problems of increasing flight resistance and wasting aviation fuel, and achieve the effect of reducing flight resistance and water adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

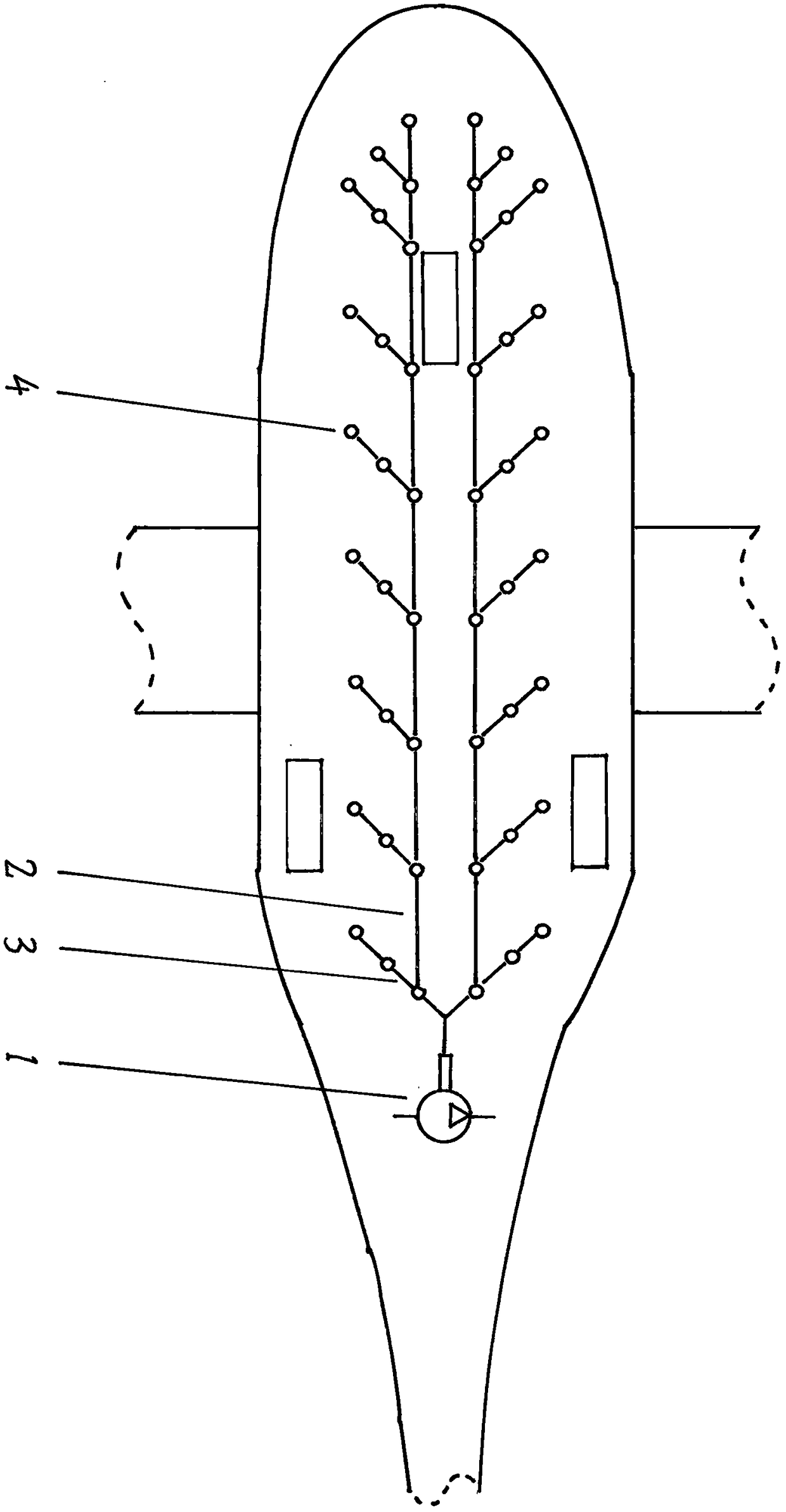

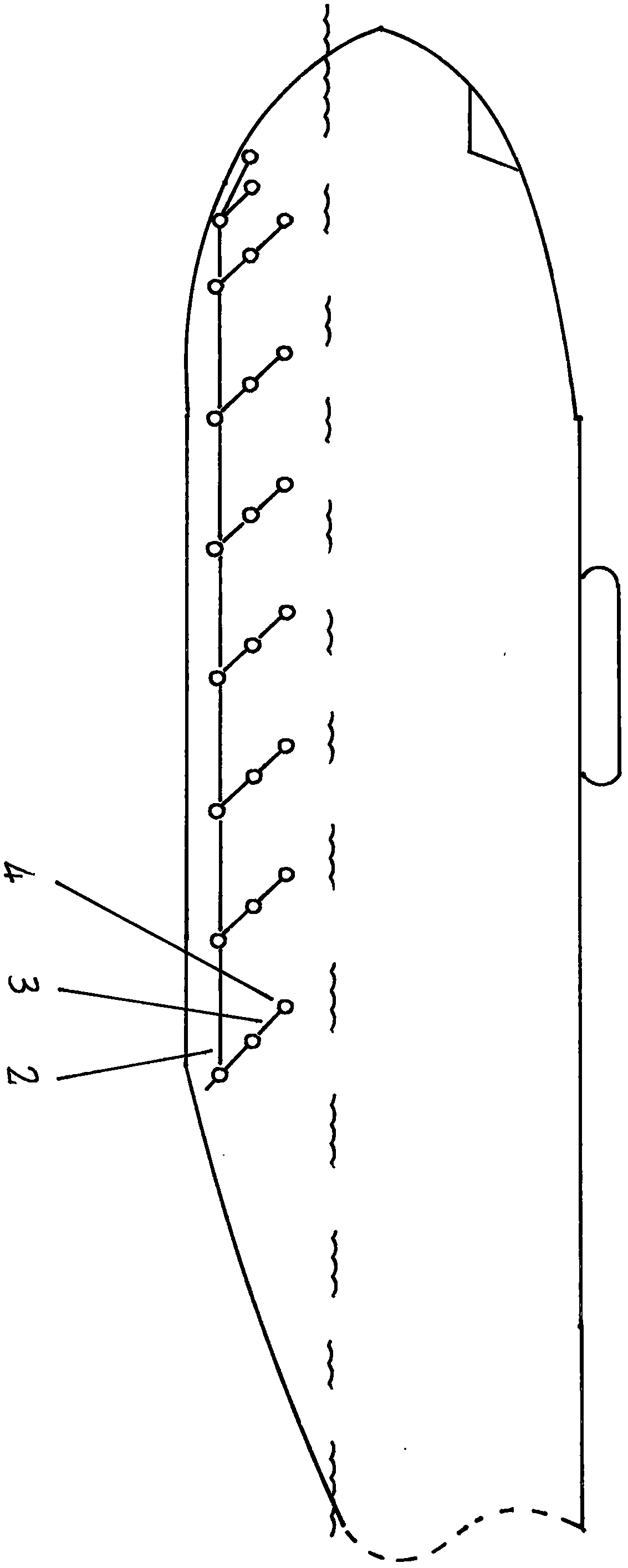

[0018] When the seaplane is about to take off on the water surface, start the air compressor (1) in the seaplane, and pressurized air is delivered to all air outlet pipes (4) after the main pipe (2) and the branch pipe (3). The strings of small bubbles continuously spewed out of the water surface, sticking to both sides of the belly of the seaplane, and many strings of small bubbles formed two curtains of bubbles on both sides of the belly of the aircraft.

[0019] When the seaplane is flying away from the water body, due to the momentum, when the bubble curtain becomes upward and backward tilting, it can still maintain the basic curtain shape, which can effectively reduce the adhesion of the water body.

[0020] After the seaplane leaves the water completely, turn off the air compressor (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com