Welding gas low-pressure early warning device

An early warning device and welding gas technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficient air pressure, inability to weld, high cost, etc., and achieve the effect of simple structure and preventing false prompts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

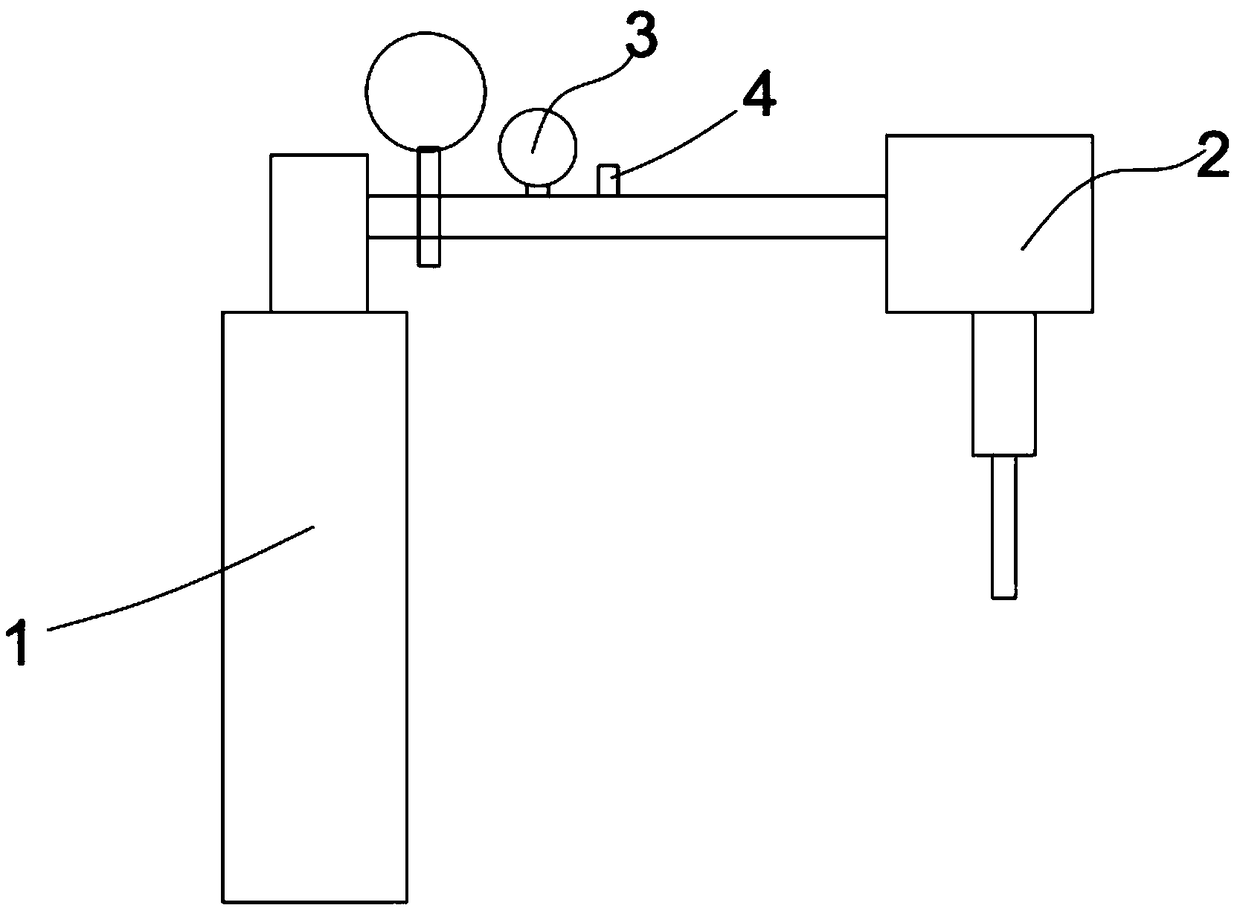

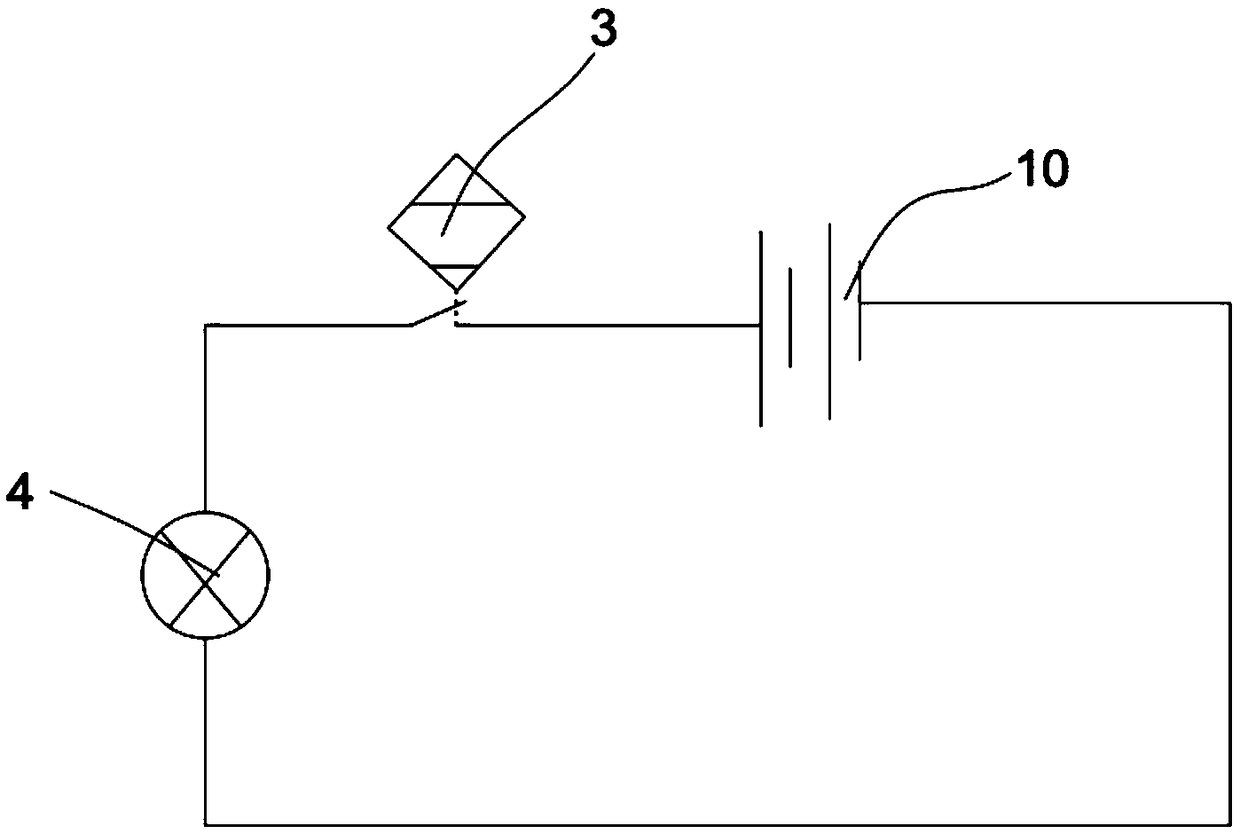

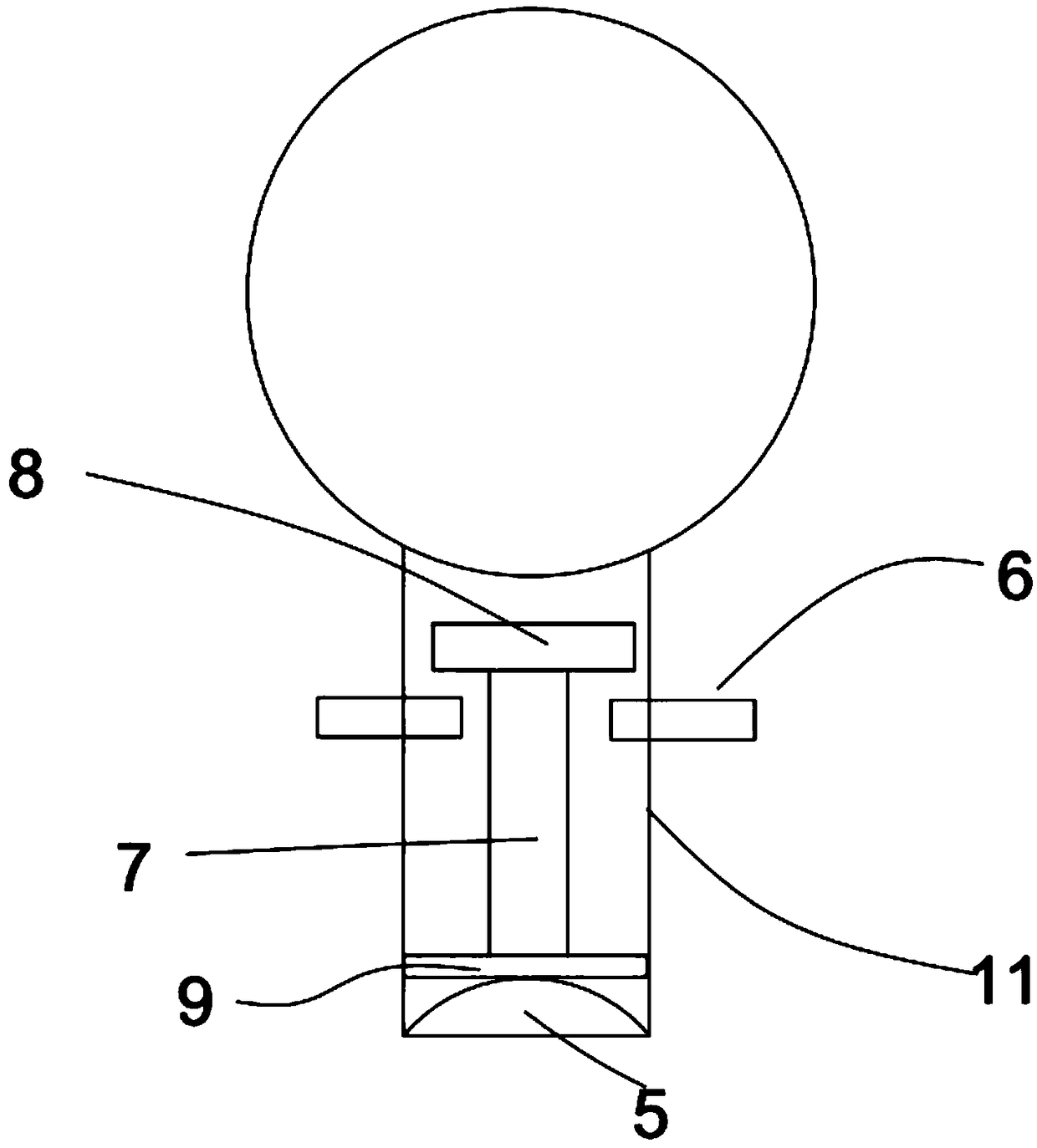

[0014] like Figure 1 ~ Figure 3 As shown, the present invention proposes a welding gas low-pressure early warning device, including several gas cylinders 1, the output end of the gas cylinder 1 is connected with a welding robot 2, and the output end of the gas cylinder 1 is connected to the welding robot 2 There is an air pressure sensor 3 and an alarm device 4, the air pressure sensor 3 is electrically communicated with the alarm equipment 4, and is connected to a power supply 10, the air pressure sensor 3 includes a casing 11, and a diaphragm 5 is arranged in the casing 11, so The diaphragm 5 is composed of a push mechanism on the top of the diaphragm 5, and two electrodes 6 are arranged on the top of the push mechanism, and the push mechanism contacts the electrodes 6 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com