Loading production line for boxed letter biscuits and boxing method for letter biscuits

A production line and biscuit technology, which is applied in the filling production line of boxed letter biscuits and the field of letter biscuit packing, can solve the problems of low production efficiency, low degree of automation, and difficult loading of biscuit production lines, so as to reduce labor consumption , Improve production efficiency and the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

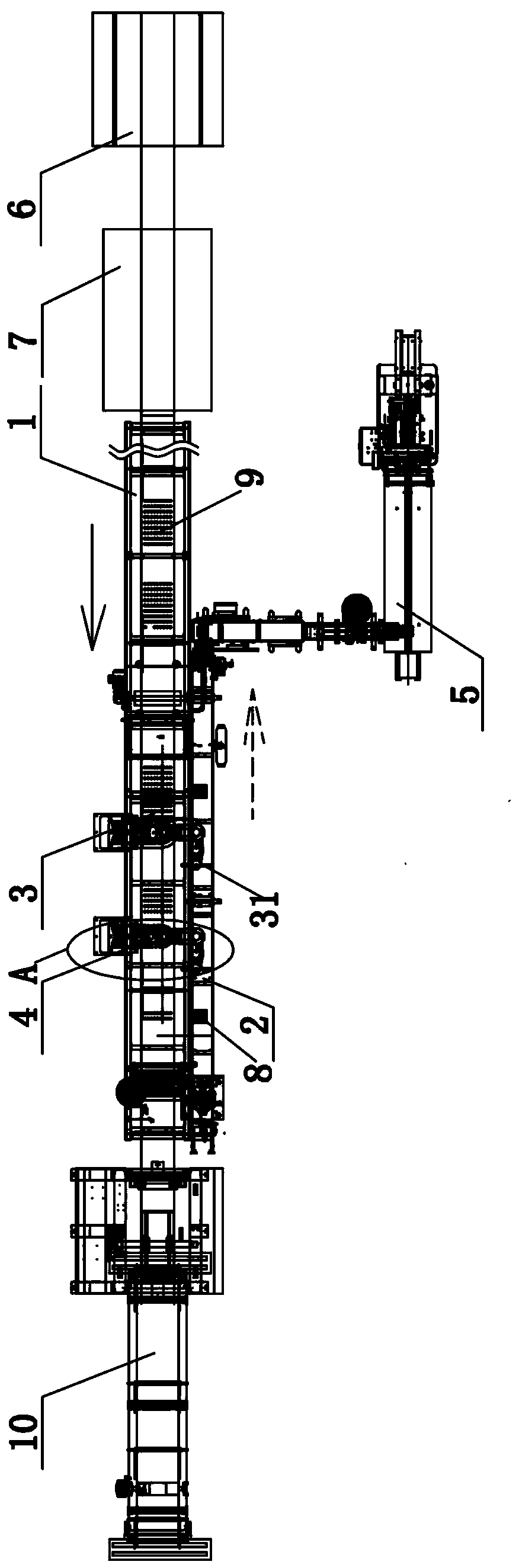

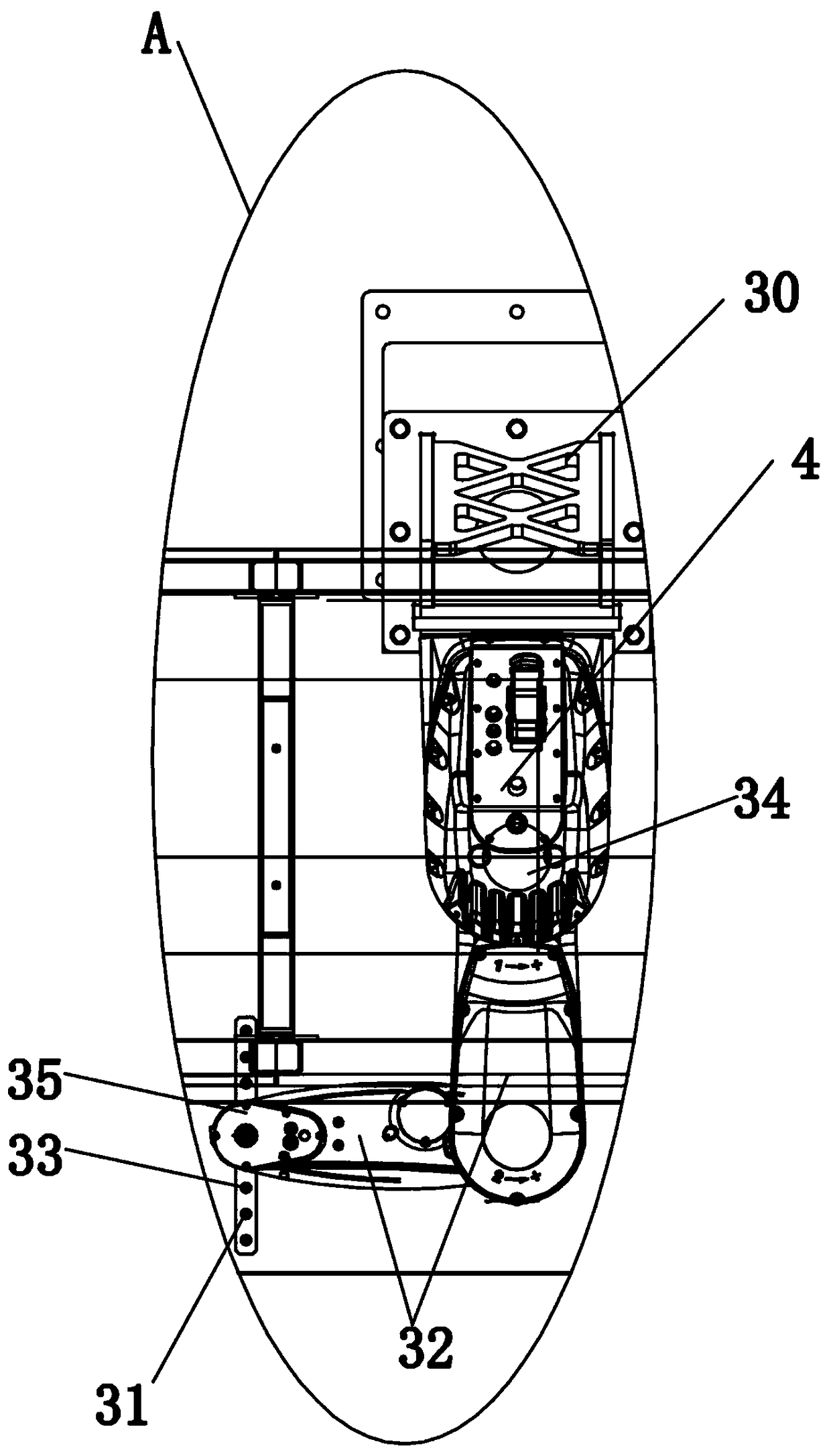

[0039] Embodiment one, such as figure 1 and image 3 As shown, a charging production line for boxed letter biscuits includes a control device (not shown in the figure), a tray conveyor line 2, a biscuit conveyor line 1, at least two grasping robots 3, 4, a packaging machine 5 and Residue recovery device 10.

[0040] The control device (not shown in the figure) is used to control the operation and stop of the entire charging production line.

[0041] The biscuit conveying line 1 is used to convey letter biscuits 9 row by row. The biscuit conveying line 1 is connected to the outlet of the roller printing machine 6. The roller printing machine 6 will make the letter biscuits 9 according to certain rules. The biscuits are conveyed to the biscuit conveyor line 1 in rows, and the letter biscuits 9 will enter the oven 7 for drying during the conveying process, and the letter biscuits 9 dried by the oven 7 are conveyed to the grabbing robot 3 by the biscuit conveyor line 1, 4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com