Low separation load joint with flexible self-compensation

A self-compensating and flexible technology, applied in space navigation equipment, space navigation equipment, space navigation aircraft, etc., can solve problems such as small fit gap between plug and socket, difficult inspection of excess, and risk of excess, to achieve separation The effect of high reliability, elimination of excess inconvenient removal problems, and elimination of risk of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

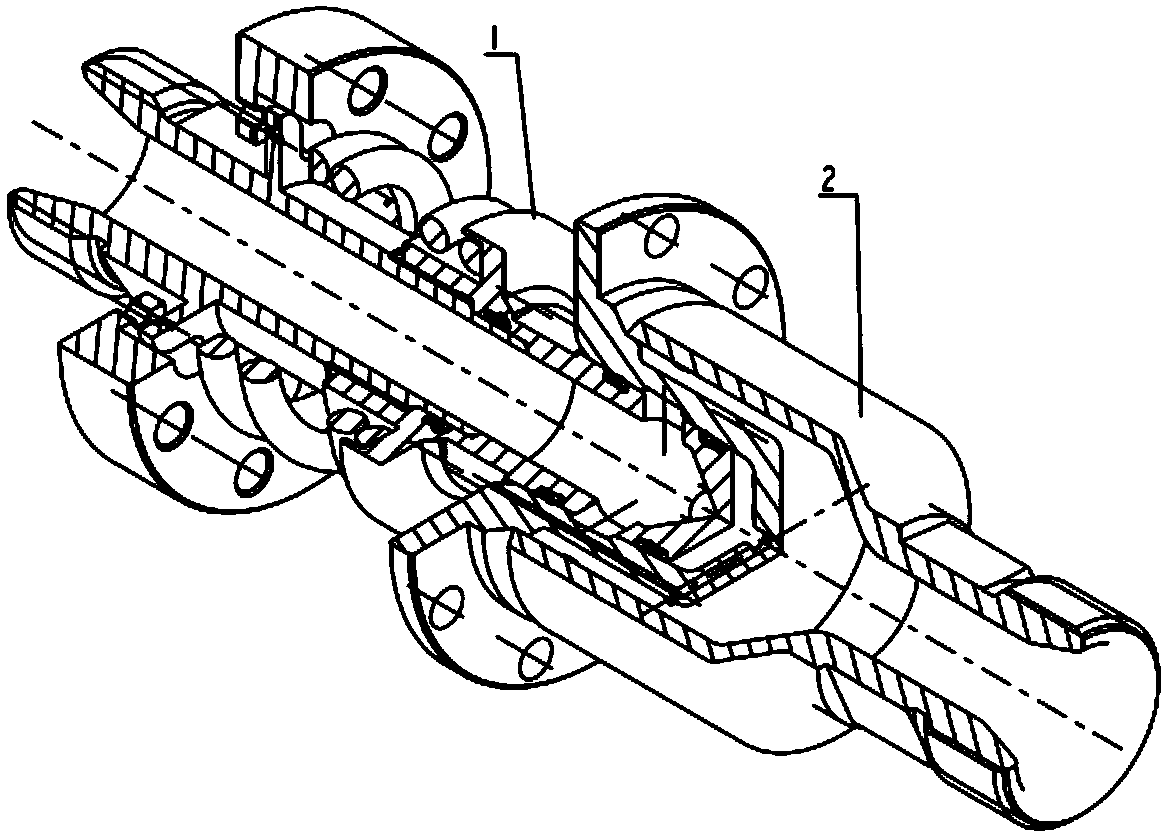

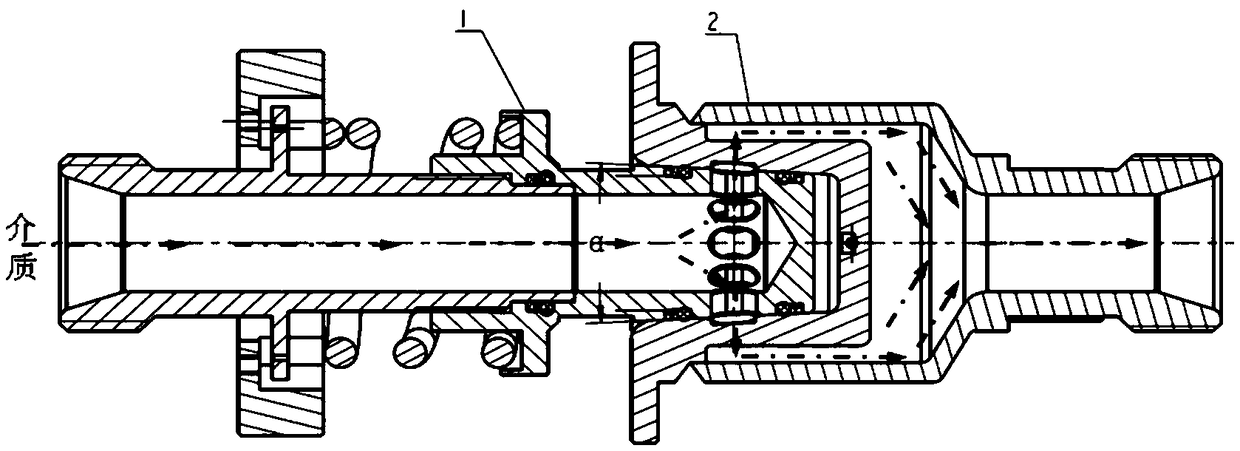

[0043] Such as figure 1 As shown, a low separation load joint with flexible self-compensation of the present invention includes a plug 1 and a socket 2, the front end of the plug 1 is connected to the rear end of the socket 2, and both the plug 1 and the socket 2 are rotary bodies. The plug 1 is installed on the ground equipment through the guide seat 13, and the rear end is connected with the ground air supply / liquid supply equipment, such as image 3 As shown, the plug 1 includes a plug body 11, a fixing seat 14, a guide seat 13 and a spring 12. The plug body 11 has a hollow inner cavity structure, and the inner cavity of the plug body 11 is a plug body channel. Such as Figure 5 As shown, the front part of the plug body 11 is a conical surface, and two front and rear outer annular sealing grooves are arranged on the conical surface structure. Sealing rings are respectively arranged in the two outer annular sealing grooves, and the outer annular sealing groove near the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com