Light-transmitting real wood automobile interior trim part and preparation process thereof

A technology for automotive interior parts and preparation technology, which is applied in the field of real wood car interior parts, can solve problems such as single effect and inability to meet the decorative effect or decorative pattern of car interior parts, and achieve the effect of enhancing style and strong sense of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Follow the steps below to produce a figure 2 The light-transmitting real wood car interior parts of the font, step 1, film raw material preparation: cut the transparent PC film of standard size, the film thickness is 0.8mm; step 2, film pattern printing: first check the pattern through the film of the pattern To achieve the desired effect, determine the order of pattern printing, that is, print the pattern on one side of the black shading, make an adhesive layer on the reverse side, compare the same type of screen with film, and confirm that the pattern is consistent; then start printing the pattern, and draw the positioning on the black shading surface of the film line, on the screen, adjust the position of the screen to ensure that it is consistent with the positioning line of the film, and lock the screen frame; then deploy black ink, that is, add 50% of IMB-HF 009 adhesive and 10% of IPX-HF 979 black to IPX-HF 979 black Hardener 10% and 50% diluent use vinyl triami...

Embodiment 2

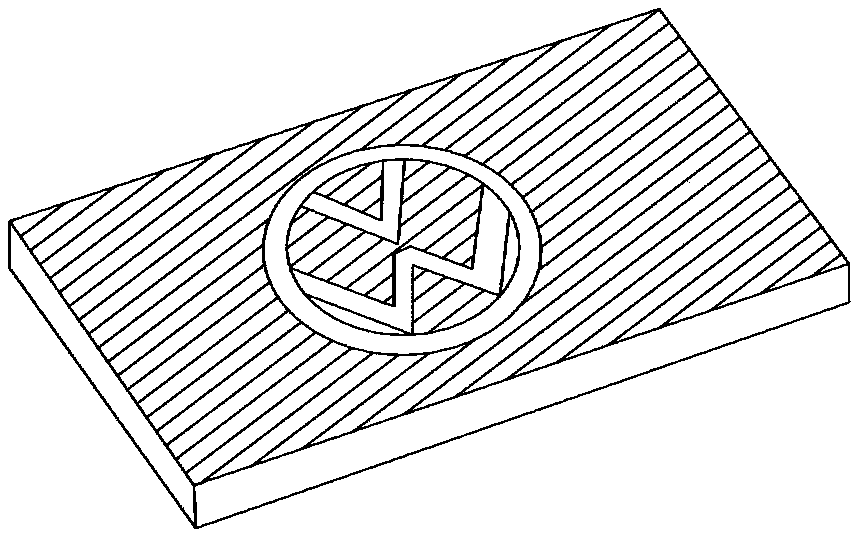

[0051] Different from Example 1, what is prepared in this example can be shown as image 3 LOGO's light-transmitting real wood car interior parts, specifically include the following steps: Step 1, film raw material preparation: cut transparent PC film of standard size, film thickness 0.7mm; Step 2, film pattern printing: in the middle of the transparent film Print the ink layer on one side of layer 2 to obtain the desired pattern; first check whether the pattern can achieve the expected effect through the film of the pattern, and determine the order of pattern printing, that is, print the pattern on one side with black light-shielding, make an adhesive layer on the reverse side, and compare it with film For the same type of screen, make sure that the pattern is consistent; then print the pattern, draw the positioning line on the film, go to the screen, adjust the position of the screen to ensure that it is consistent with the positioning line of the film, and lock the screen fr...

Embodiment 3

[0053] Different from Example 1, what is prepared in this example can be shown as Figure 4Graphic light-transmitting real wood automotive interior parts, specifically include the following steps: Step 1, film raw material preparation: cut transparent PC film of standard size, film thickness is 0.5mm; Step 2, film pattern printing: first pass the pattern Check whether the pattern can achieve the expected effect, determine the order of pattern printing, that is, print the pattern on one side of the black light-shielding, make an adhesive layer on the reverse side, use the film to compare the screen of the same type, and confirm that the pattern is consistent; then print on one side of the film Print the pattern, draw the positioning line on the film, surf the screen, adjust the position of the screen to ensure that it is consistent with the positioning line of the film, and lock the screen frame; then mix black ink, that is, add 50% IMB-HF to IPX-HF 979 black 009 adhesive, 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com