Fault processing system of multi-terminal flexible direct-current transmission line and control method of fault processing system

A DC transmission line, multi-terminal flexible technology, applied in the direction of emergency treatment AC circuit layout, power transmission AC network, etc., can solve the problems of increasing current limiter input, complex structure of current limiter, unfavorable multi-terminal flexible DC system widely used, etc. Achieve the effect of reducing the requirements of breaking capacity and breaking speed, and reducing the rising speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

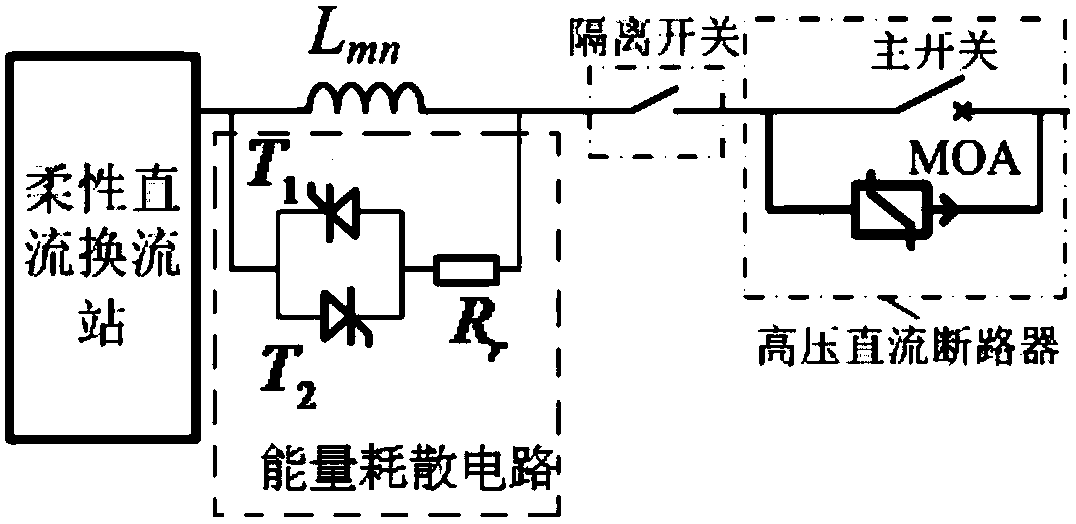

[0034] The basic idea of the present invention is to add a current-limiting inductance and an energy dissipation circuit to the existing multi-terminal flexible direct current transmission line, the current-limiting inductance is used to limit the fault current, and the energy dissipation circuit is used to dissipate the energy of the fault current.

[0035] combined with figure 1 , this embodiment provides a fault handling system for a multi-terminal flexible DC transmission line, including a high-voltage DC circuit breaker connected to each output terminal of the flexible DC converter station, and a high-voltage DC circuit breaker connected to the output terminal of the flexible DC converter station. The current-limiting inductance Lmn and the energy dissipating circuit betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com