Cigarette manufacturing equipment spot inspection analysis method and system

A technology for manufacturing equipment and analysis methods, applied in manufacturing computing systems, instruments, data processing applications, etc., it can solve the problems of single point inspection records, scattered record data, and difficulty in deep mining, etc. order, ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

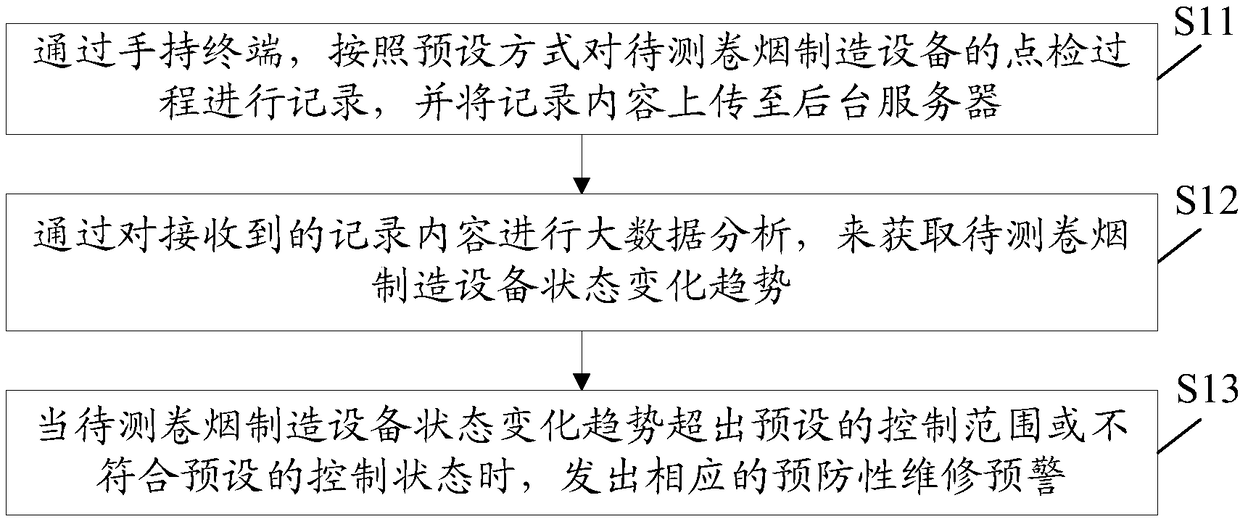

[0038] The embodiment of the present invention provides a method for point inspection and analysis of cigarette manufacturing equipment, see figure 1 , the method can include:

[0039] Step S11, record the spot inspection process of the cigarette manufacturing equipment to be tested according to the preset method through the handheld terminal, and upload the recorded content to the background server.

[0040] In this embodiment, in order to overcome the existing problems of monotonous equipment point inspection methods, low data collection efficiency, scattered data collection, and insufficient data mining, handheld terminals (such as smart phones, tablet computers, etc.) are used to test Record the inspection process of cigarette manufacturing equipment (including recording inspection data and description of equipment problems), which can be carried out in any one or more ways of numbers, text, pictures, voice and video, and can comprehensively and continuously Information c...

Embodiment 2

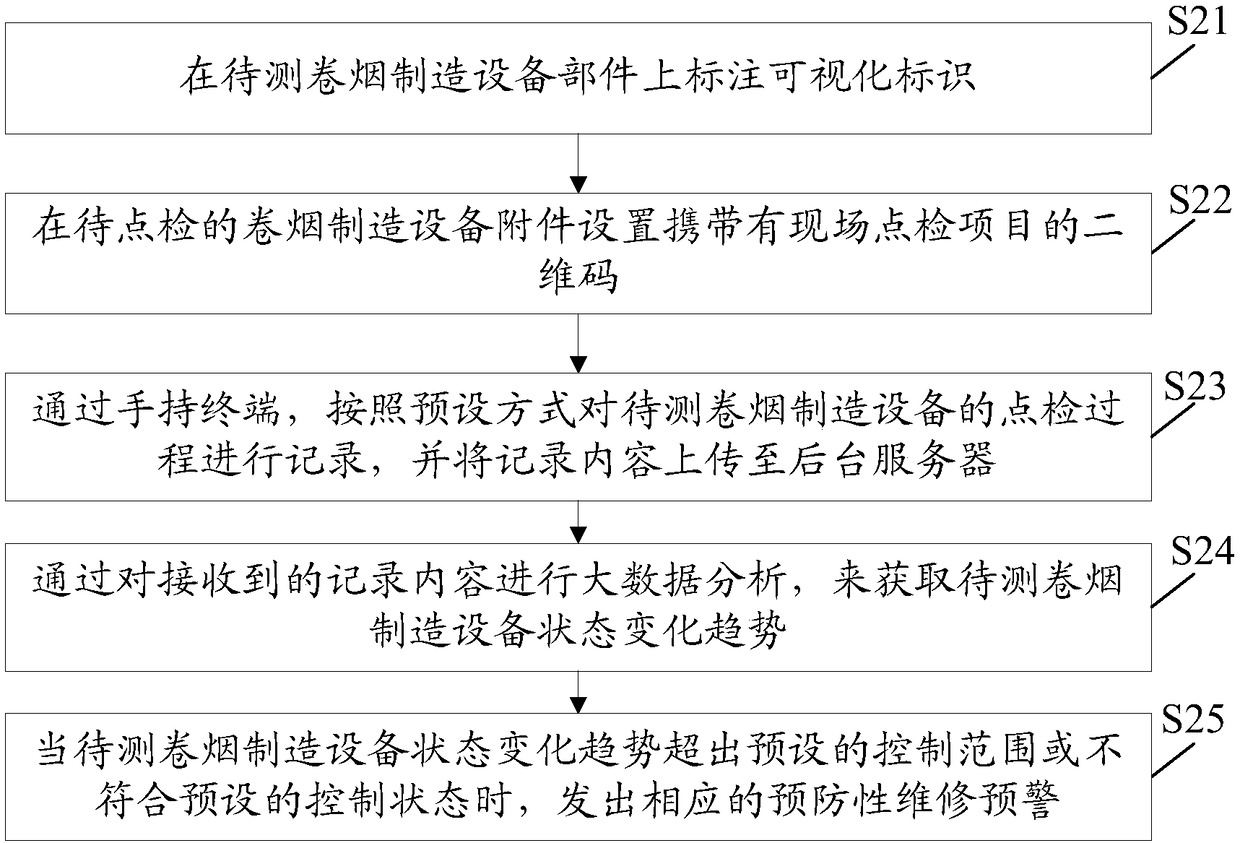

[0053] The embodiment of the present invention provides a kind of inspection and analysis of cigarette manufacturing equipment, see figure 2 , the method can include:

[0054] In step S21, a visual mark is marked on the components of the cigarette manufacturing equipment to be tested for visual management by on-site inspection staff.

[0055] In this embodiment, visual marks can be marked on the components of the cigarette manufacturing equipment to be tested, as the inspection site points, for the on-site inspection staff to conduct visual management, so as to reduce the influence of human factors on the inspection results and standardize the inspection The process makes the inspection results more consistent.

[0056] Step S22, setting a QR code carrying on-site inspection items at the attachment of the cigarette manufacturing equipment to be inspected, for on-site inspection staff to download corresponding on-site inspection items.

[0057] In this embodiment, in order t...

Embodiment 3

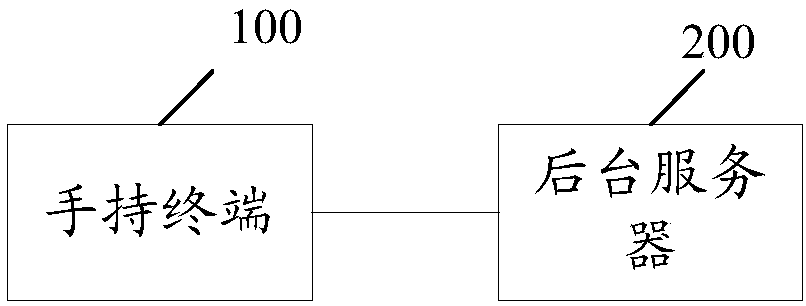

[0070] The embodiment of the present invention provides a point inspection and analysis system for cigarette manufacturing equipment, which realizes the method described in embodiment 1 or 2, see image 3 , the system may include: at least one handheld terminal 100 (such as a smart phone, a tablet computer, etc.) and a background server 200 (such as an industrial-grade server), and each handheld terminal 100 is communicatively connected to the background server 200 .

[0071] The handheld terminal 100 is used for employees to record the inspection process of the cigarette manufacturing equipment to be tested according to the preset method, and upload the recorded content to the background server

[0072] In this embodiment, in order to overcome the existing problems of monotonous equipment inspection methods, low data collection efficiency, scattered data collection, and insufficient data mining, a handheld terminal 100 (such as a smart phone, a tablet computer, etc.) is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com