A Method for Measuring the Wall Thickness of Metal Pipeline Using Electromagnetic Eddy Current Method

A metal pipeline and electromagnetic eddy current technology, which is applied in the direction of electromagnetic measuring devices, using electromagnetic means, and electric/magnetic thickness measurement, can solve the problems of reducing the detection speed of pipelines, achieve the effect of improving measurement accuracy and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

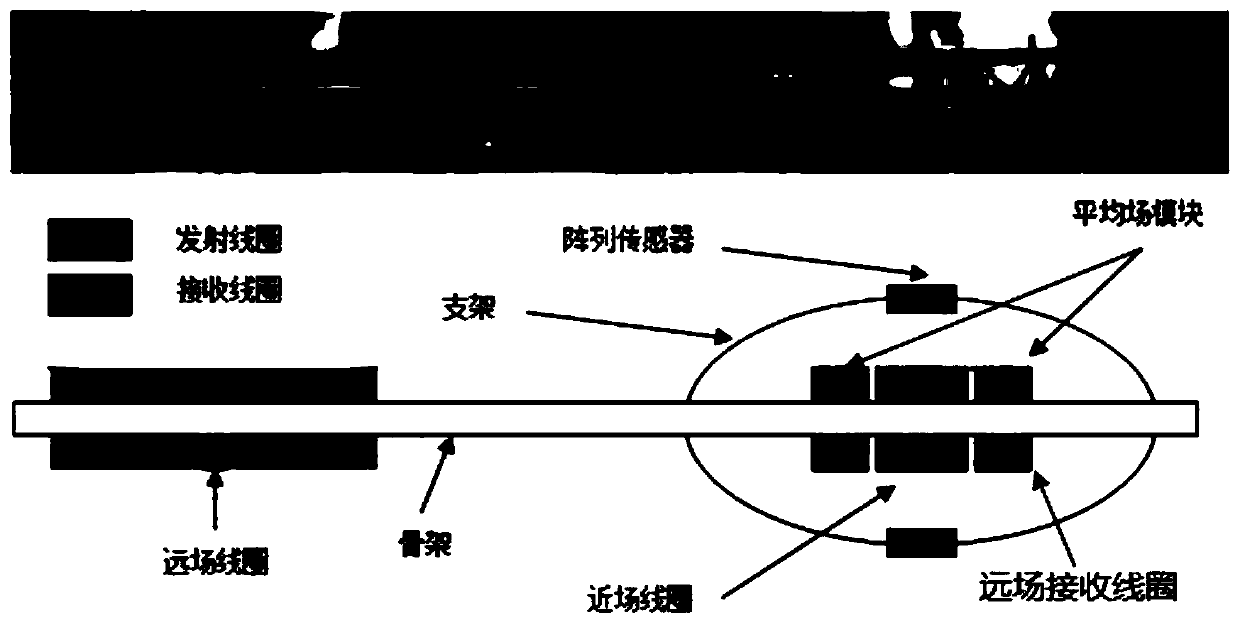

[0038] figure 1 It is a schematic diagram of a method for detecting the wall thickness of a metal pipeline by using the electromagnetic eddy current method of the present invention.

[0039] In this example, if figure 1 Shown, a kind of method of the present invention utilizes electromagnetic eddy current method to detect metal pipeline wall thickness, comprises the following steps:

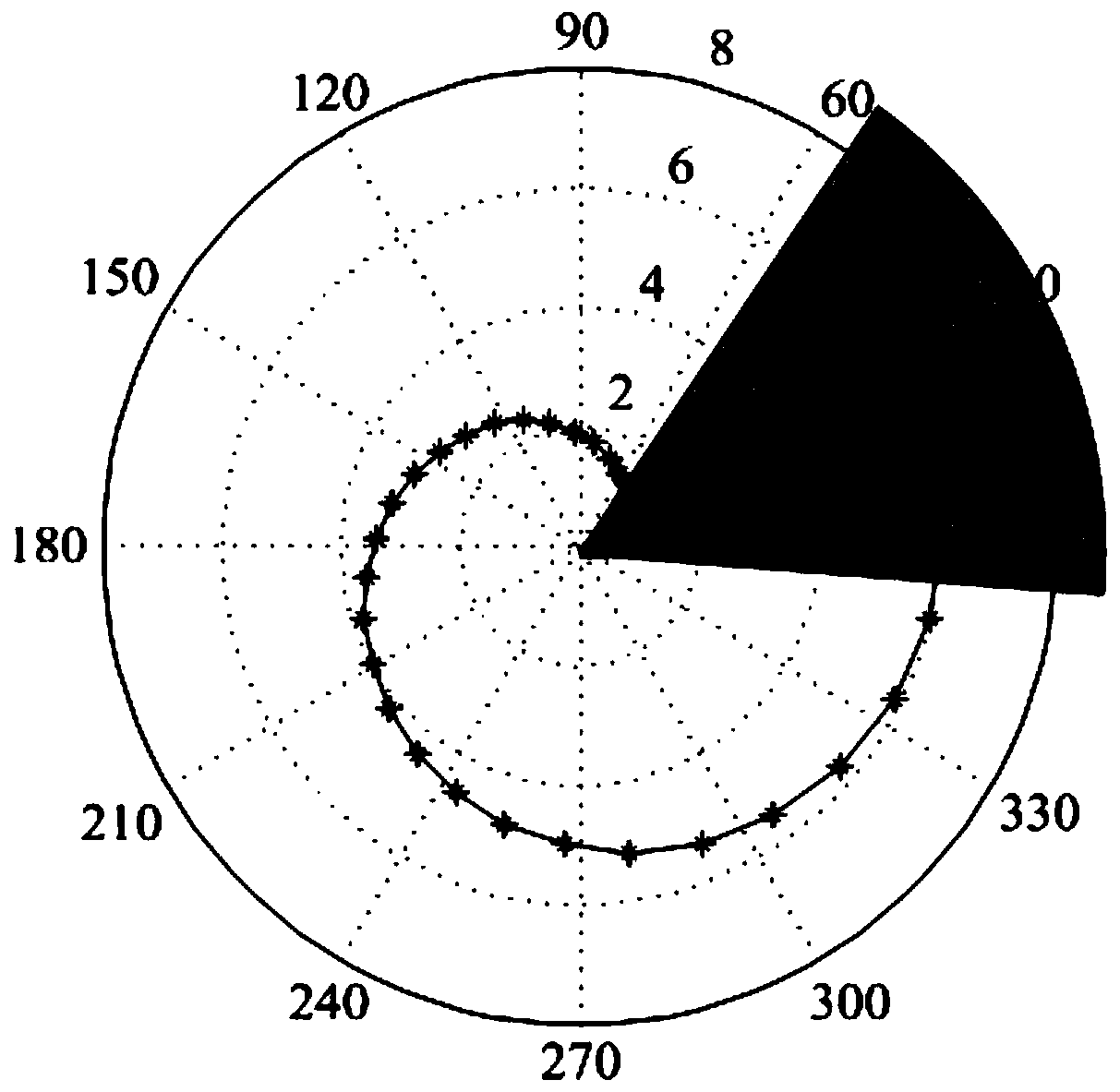

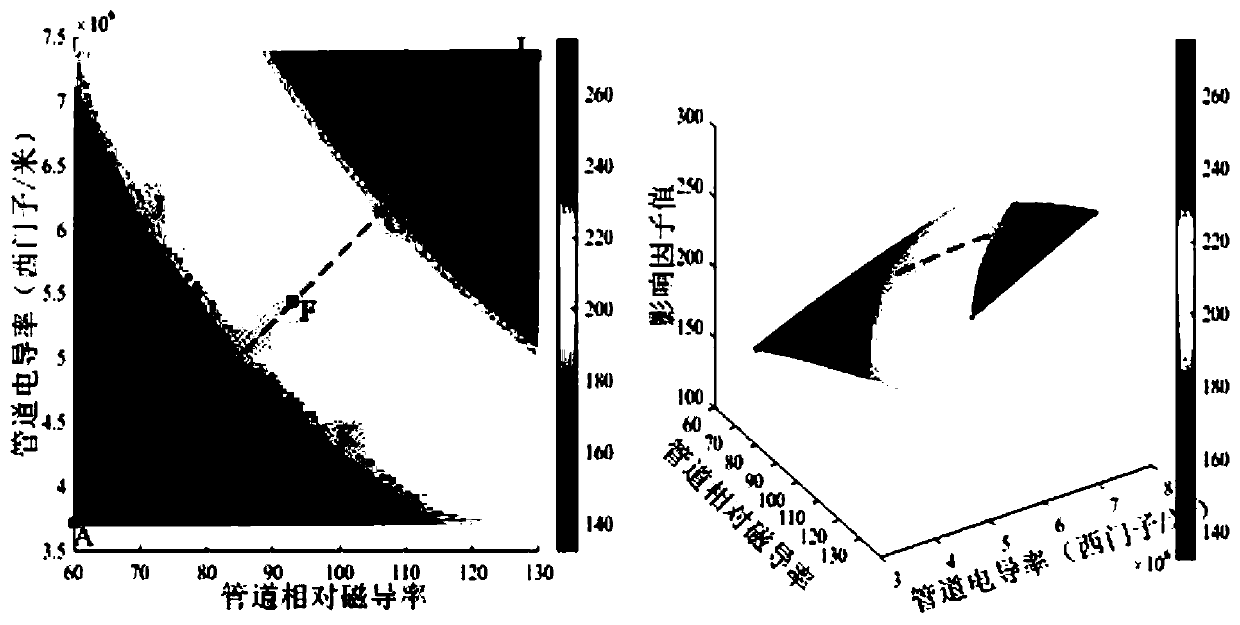

[0040] S1. The influence of pipe wall thickness on the detection signal phase is analyzed by ANASY simulation. As the pipe wall thickness increases, the amplitude of the detection signal decreases gradually, and the phase lag increases gradually. If the pipe wall thickness continues to increase, in the process of calculating the phase each time, if the phase at the current moment is greater than 330°, and the phase at the next moment is less than 30°, it means that the phase lag at this moment is greater than 360°. The phase lag is equal to the phase lag when the tube wall is thin. This phenom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com