Slot nozzle for instant freezer

A quick-freezing machine and slit technology, which is applied in the field of slit nozzles for quick-freezing machines, can solve the problem of low freezing rate of frozen products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the operation process and creative features realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

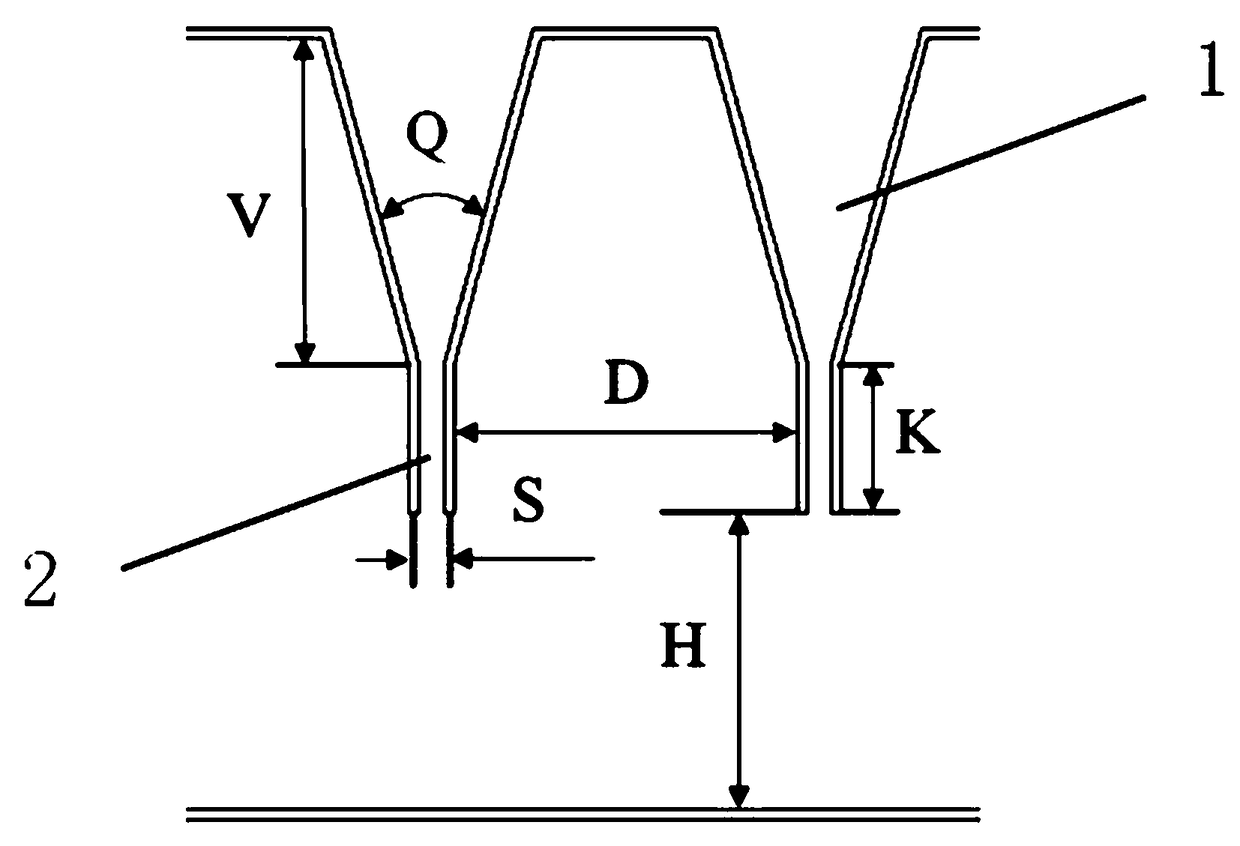

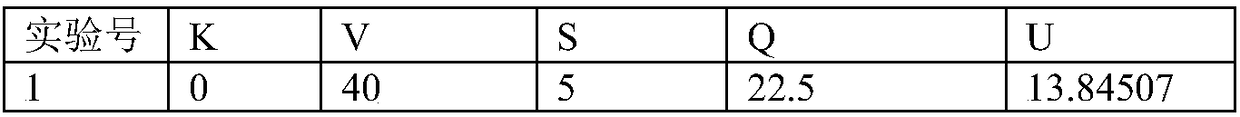

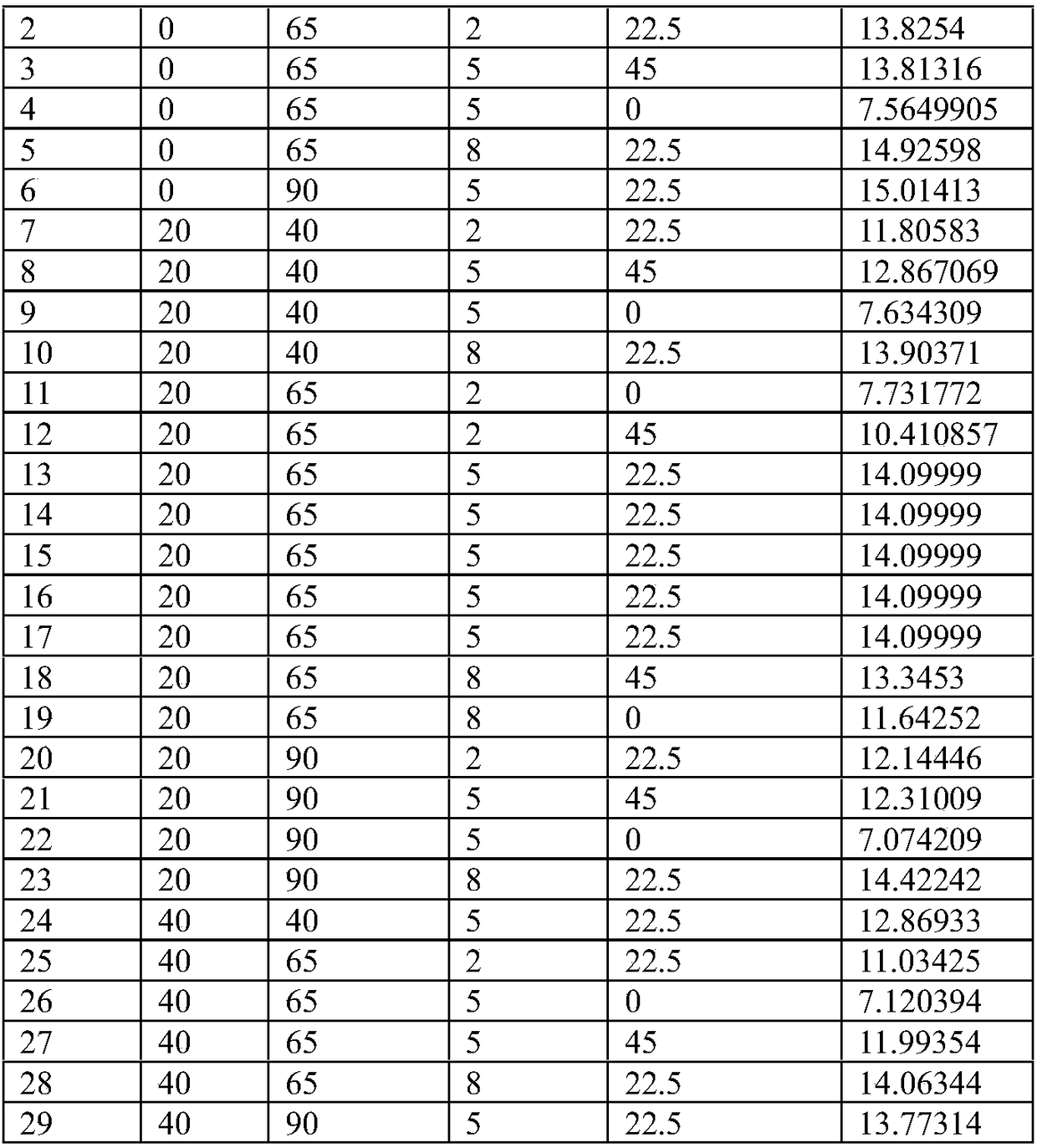

[0010] A slit nozzle for a quick-freezing machine includes a V-shaped flow guide groove and a slit nozzle; Two strip-shaped plates arranged obliquely, the length direction of the strip-shaped plates is located in the horizontal direction, the cross section of the V-shaped diversion groove is rectangular, the longitudinal section in the width direction is an inverted trapezoid, and the two adjacent V-shaped diversion grooves The upper part is connected by a flat plate; the slit nozzle includes two strip plates arranged in parallel and vertically. The lower ends of the two strip plates of the groove are connected. The length of the slit nozzle is 1000-2000mm, the height of the V-shaped diversion groove 1 is 40-90mm, the opening angle of the V-shaped diversion gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com