Split three-flange drill pipe centralizer for coal mine

A centralizer and split-type technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of triangular drill pipe centralizers, etc., and achieve the effects of low cost, reliable installation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

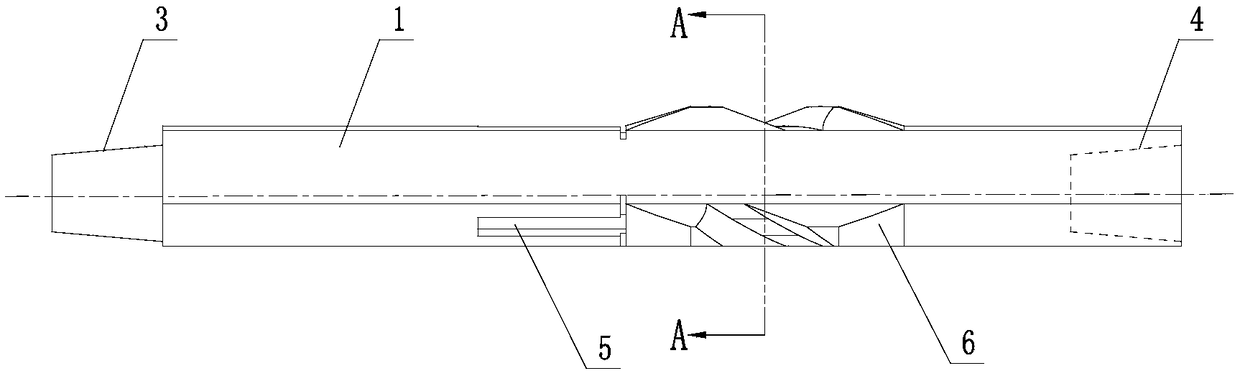

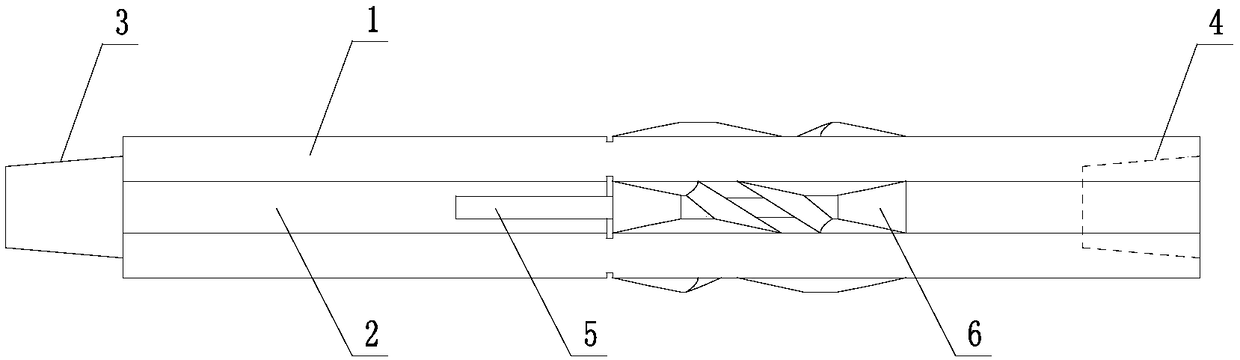

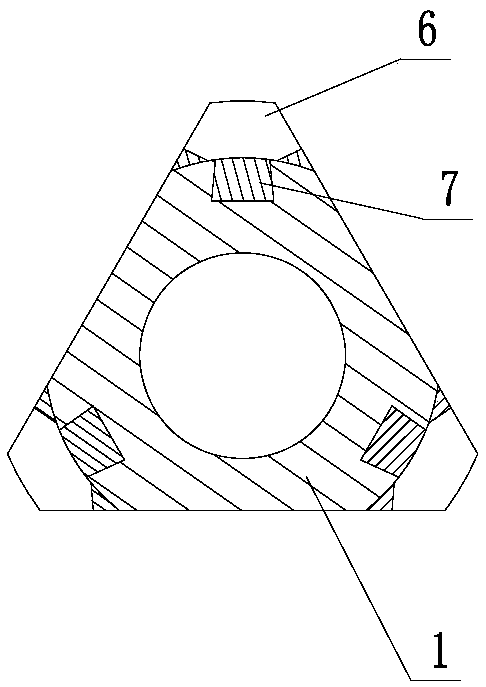

[0034] Such as Figure 1 to Figure 12 As shown, the split type coal mine triangular drill pipe centralizer of the present invention includes a centralizer main body 1 , a centralizing assembly and a spring clip 9 .

[0035] The main body 1 of the centralizer is a triangular prism with the same diameter as the triangular drill pipe. The main body 1 of the centralizer is a hollow structure. The two ends of the centralizer are respectively provided with a pin joint 3 and a box joint 4. The centralizer main body 1 is connected with the triangular drill pipe through the pin joint 3 and the box joint 4. The three ribs 2 of the centralizer main body 1 are respectively along the A chute 5 is provided in the axial direction, and the chute 5 is divided into a dovetail section 51 and a square section 52. The opening width of the square section 52 is greater than that of the dovetail section 51. The dovetail section 51 and the square section 52 The widths of the bottom surfaces of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com