The construction method of dismantling the cross-beam support of the portal pier on the existing railway line at a short distance

A technology for wired portal piers and beam supports, which is used in construction, building maintenance, building construction, etc., can solve the problems of short distances, sometimes only more than 50 centimeters in distance, narrow construction work space, and difficult engineering construction. The effect of the removal of the bottom film, the short blocking time and the fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

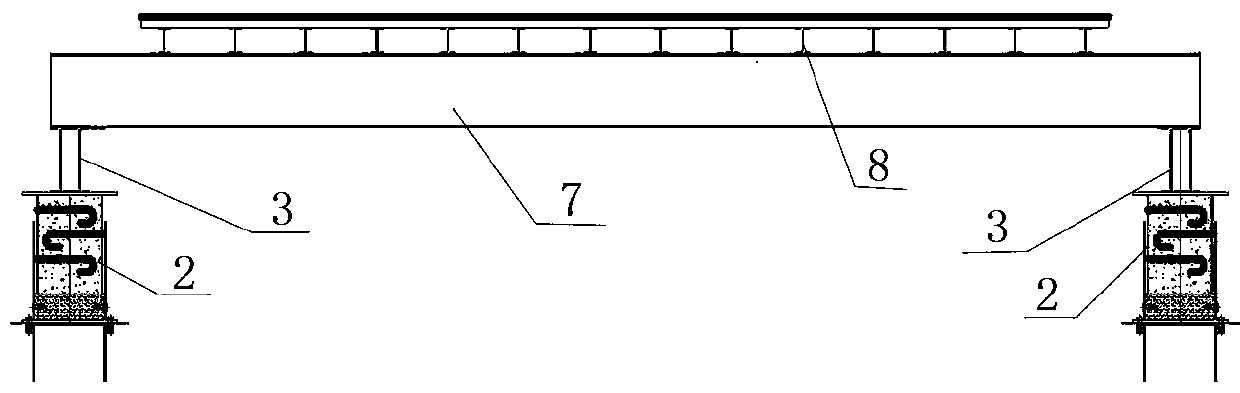

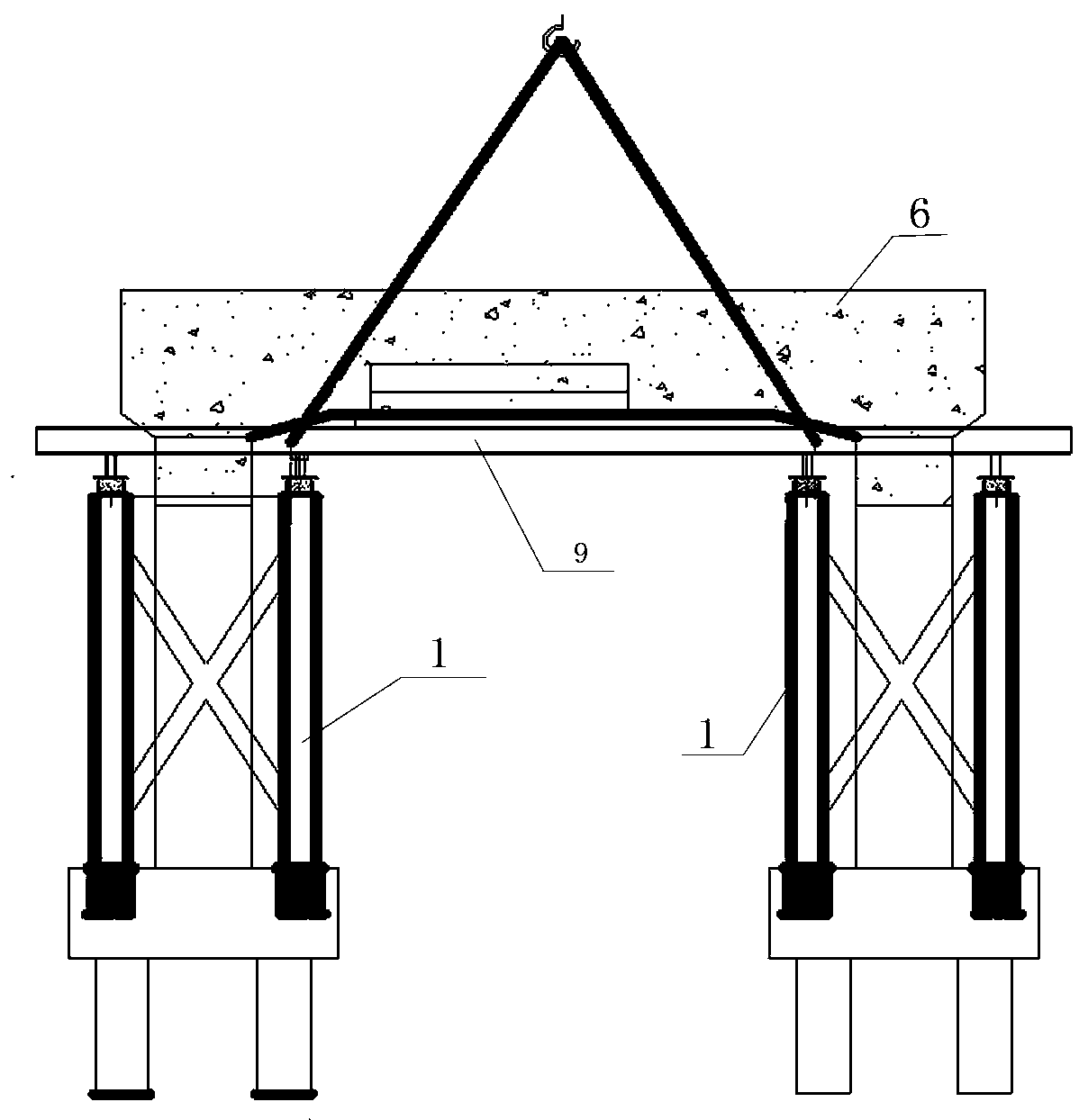

[0025] In conjunction with the accompanying drawings, the operating points in this construction method will be described in detail.

[0026] Removal of bamboo plywood on the construction platform (outside the blockade point)

[0027] The bamboo plywood of the construction platform shall be removed manually. The order of dismantling starts from the end far away from the material transport step ladder to the end of the step ladder. When dismantling, be careful not to move the insulating board at the bottom of the bamboo plywood.

[0028] Remove insulation boards, decompose I56 I-beam longitudinal beams, remove protective railings and dense mesh (in blockade points)

[0029] (1) Manually remove the protective railing and the dense mesh, and remove the sequence of dense mesh → railing crossbar → railing pole.

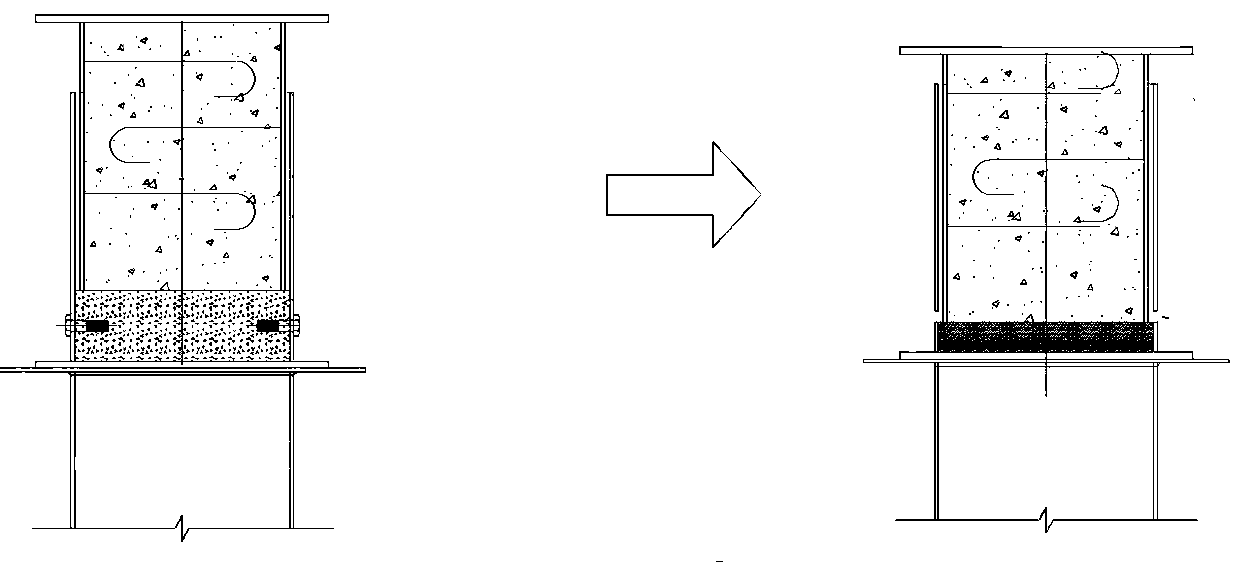

[0030] (2) Removal of insulation boards and disassembly of I56 I-beam longitudinal beams: manual removal of insulation boards, from the side of the main body of portal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com