Highly wear-resistant, waterproof and antibacterial wood-plastic floor and preparation method thereof

A wood-plastic floor, high wear-resistant technology, applied in the field of wood-plastic floor materials, can solve the problems of mildew, poor wear resistance, waterproof and antibacterial performance, easy expansion and deformation, etc., to improve lubrication, improve waterproof ability, and increase density and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

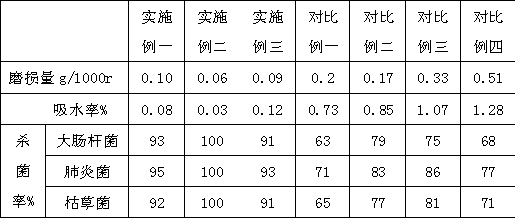

Embodiment 1

[0021] The invention provides a high wear-resistant waterproof antibacterial wood-plastic floor, comprising the following parts by weight of raw materials: 20 parts of high-density polyethylene, 20 parts of polyvinyl chloride, 40 parts of plant fiber, 8 parts of carbon fiber, 2 parts of tungsten disulfide, 1 part of n-octacosanol, 2 parts of 2,4,5-triamino-6-hydroxypyrimidine sulfate, 4 parts of polyoxyethylene laurate, 2 parts of calcium stearoyl lactate, 2 parts of flame retardant, 1 part of antibacterial agent and 1 part of compatibilizer; the flame retardant is a mixture of phosphate ester and zinc borate, and the mass ratio of phosphate ester and zinc borate is 3:1.

[0022] The preparation method includes the following steps:

[0023] S1. Add the specific gravity of n-octacosanol and 2,4,5-triamino-6-hydroxypyrimidine sulfate into the ultrasonic instrument, add n-octacosanol and 2,4,5-triamino -1.8 times the total mass of 6-hydroxypyrimidine sulfate in water, ultrasonically ...

Embodiment 2

[0028] The present invention proposes a high wear-resistant waterproof antibacterial wood-plastic floor, comprising the following parts by weight of raw materials: 28 parts of high-density polyethylene, 28 parts of polyvinyl chloride, 50 parts of plant fiber, 12 parts of carbon fiber, 3.5 parts of tungsten disulfide, 5 parts of n-octacosanol, 2.5 parts of 2,4,5-triamino-6-hydroxypyrimidine sulfate, 6 parts of polyoxyethylene laurate, 3.5 parts of calcium stearoyl lactate, 3.5 parts of flame retardant, 2 parts of antibacterial agent and 2 parts of compatibilizer; the flame retardant is a mixture of phosphate and zinc borate, and the mass ratio of phosphate and zinc borate is 3:1.

[0029] The preparation method includes the following steps:

[0030] S1. Add the specific gravity of n-octacosanol and 2,4,5-triamino-6-hydroxypyrimidine sulfate into the ultrasonic instrument, add n-octacosanol and 2,4,5-triamino -2.2 times the total mass of 6-hydroxypyrimidine sulfate in water, ultraso...

Embodiment 3

[0035] The present invention proposes a high wear-resistant waterproof antibacterial wood-plastic floor, comprising the following parts by weight of raw materials: 35 parts of high-density polyethylene, 35 parts of polyvinyl chloride, 60 parts of plant fiber, 15 parts of carbon fiber, 5 parts of tungsten disulfide, 12 parts of n-octacosanol, 3 parts of 2,4,5-triamino-6-hydroxypyrimidine sulfate, 8 parts of polyoxyethylene laurate, 5 parts of calcium stearoyl lactate, 5 parts of flame retardant, 3 parts of antibacterial agent and 3 parts of compatibilizer; the flame retardant is a mixture of phosphate and zinc borate, and the mass ratio of phosphate and zinc borate is 3:1.

[0036] The preparation method includes the following steps:

[0037] S1. Add the specific gravity of n-octacosanol and 2,4,5-triamino-6-hydroxypyrimidine sulfate into the ultrasonic instrument, add n-octacosanol and 2,4,5-triamino -2.5 times the total mass of 6-hydroxypyrimidine sulfate in water, disperse ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com