Aseismic structure in double-shell low-temperature in-tank tank

An anti-seismic structure and low-temperature tank technology, which is applied in the direction of containers, packaging, transportation and packaging, etc., can solve the problems of leakage of internal low-temperature medium, loss of cold capacity of the low-temperature tank body, troublesome replacement, etc., and achieve the effect of avoiding medium leakage and sealing Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

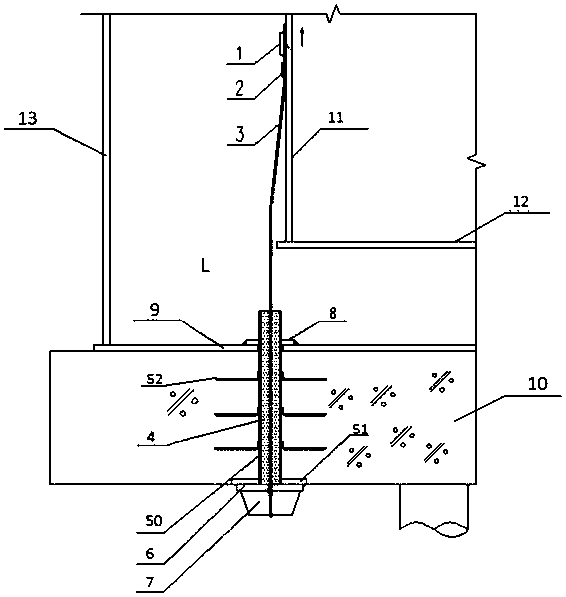

[0026] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

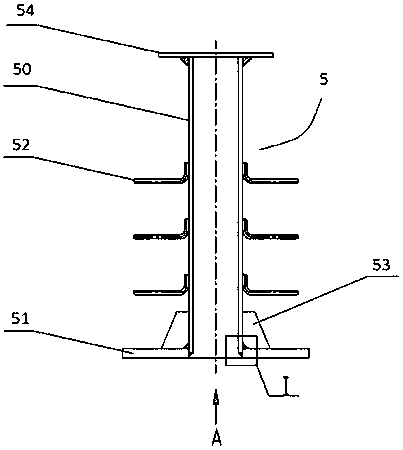

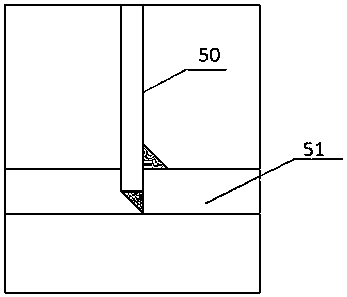

[0027] refer to figure 1 , according to the present invention, the anti-seismic structure for the inner tank of the double-shell low-temperature tank includes: the anchor belt box 5 is arranged in the cap foundation 10, the top end is exposed on the upper surface of the cap foundation 10, and passes through the outer tank bottom plate 9 and the outer tank bottom plate 9 seal welding; the cover body 6 is fixed and exposed on the lower surface of the cap foundation 10, and seals the bottom end of the anchor belt box 5; and the anchor belt 3, the lower end passes through the anchor belt box 5 and is connected to the cover body 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com