U-shaped sectional material arc-bending die and using method thereof

A profile and U-shaped technology, applied in the field of U-shaped profile bending molds, can solve the problems of being unable to process U-shaped profiles, unable to control the transmission of force, and not having the ability to bend lateral arcs of such U-shaped profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail.

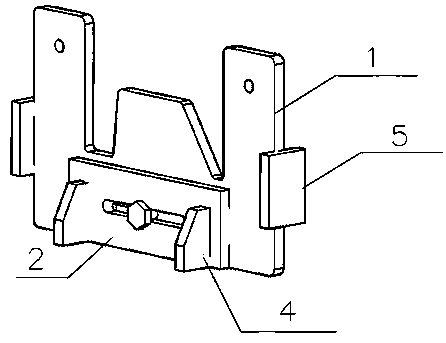

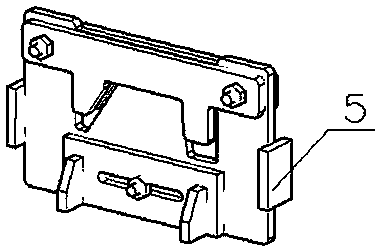

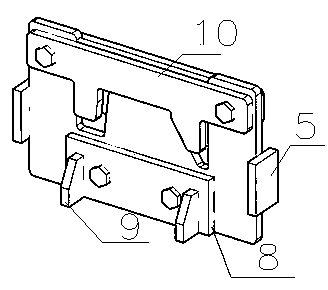

[0031] A kind of U-shaped profile bending mold, comprises main board, is provided with U-shaped groove 1 6 above the main board, main board comprises guiding type main board 1 and fixed type main board 2, is provided with a bolt hole in the middle of the bottom of guiding type main board 1, guiding type main board 1 There are guide plates 2 on both sides of the bottom bolt hole, and a hollow U-shaped groove II 3 is provided in the middle part of the guide plate 2. Through the connection of bolts, on the one hand, the main board can be displaced along the fixed track, and on the other hand, it can prevent the main board from moving up and down. The two sides of the guide plate 2 are provided with the guide plate stiffener 4, the bottom of the fixed main board 7 is provided with two bolt holes, the two sides of the bottom of the fixed main board 7, that is, the two sides of the bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com