Efficient and automatic detecting and sorting system for cosmetic brushes

An automatic detection and sorting system technology, applied in sorting and other directions, can solve problems such as inconsistent marking positions, glue overflow, error-prone, etc., and achieve the effects of avoiding sorting error rates, improving production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

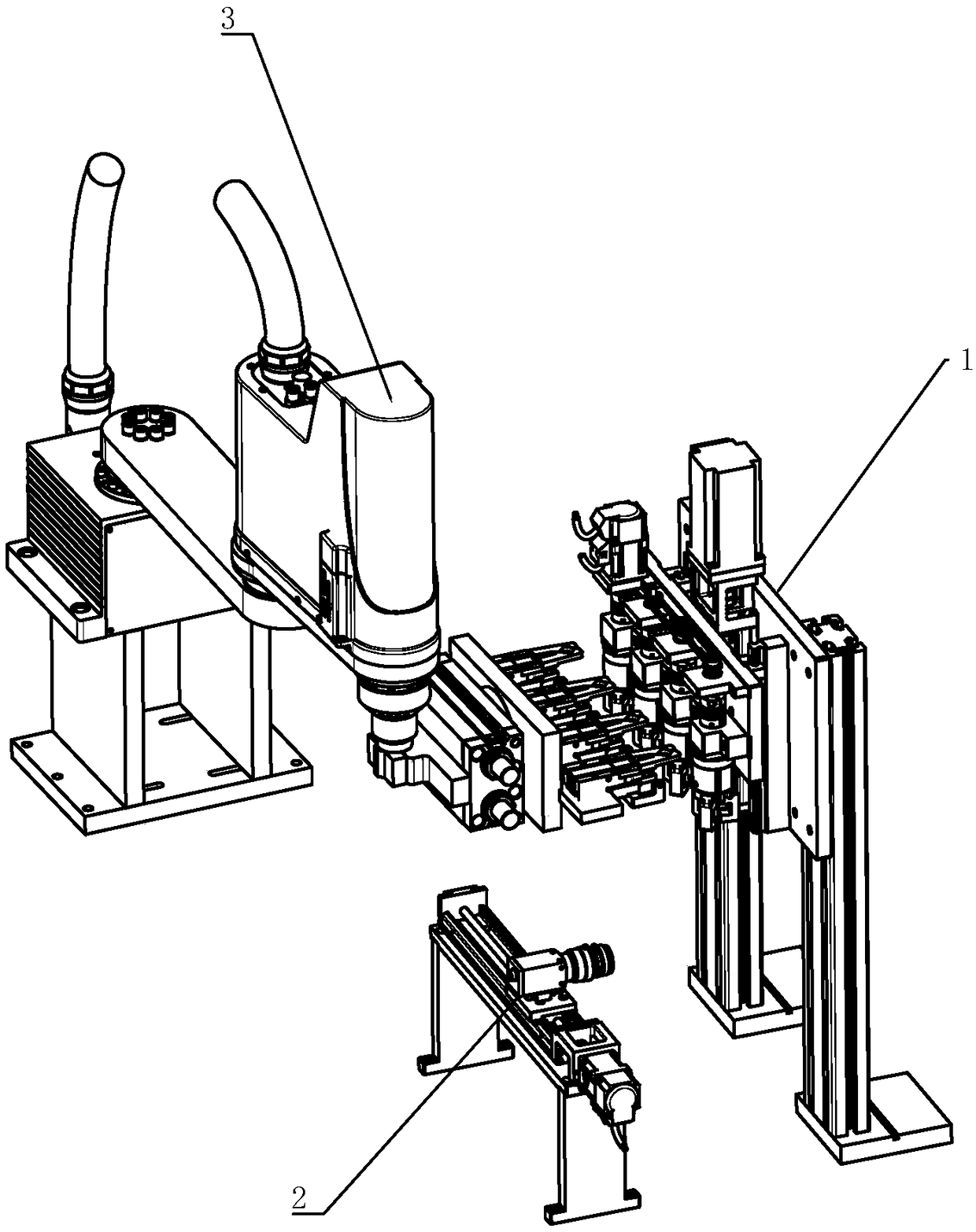

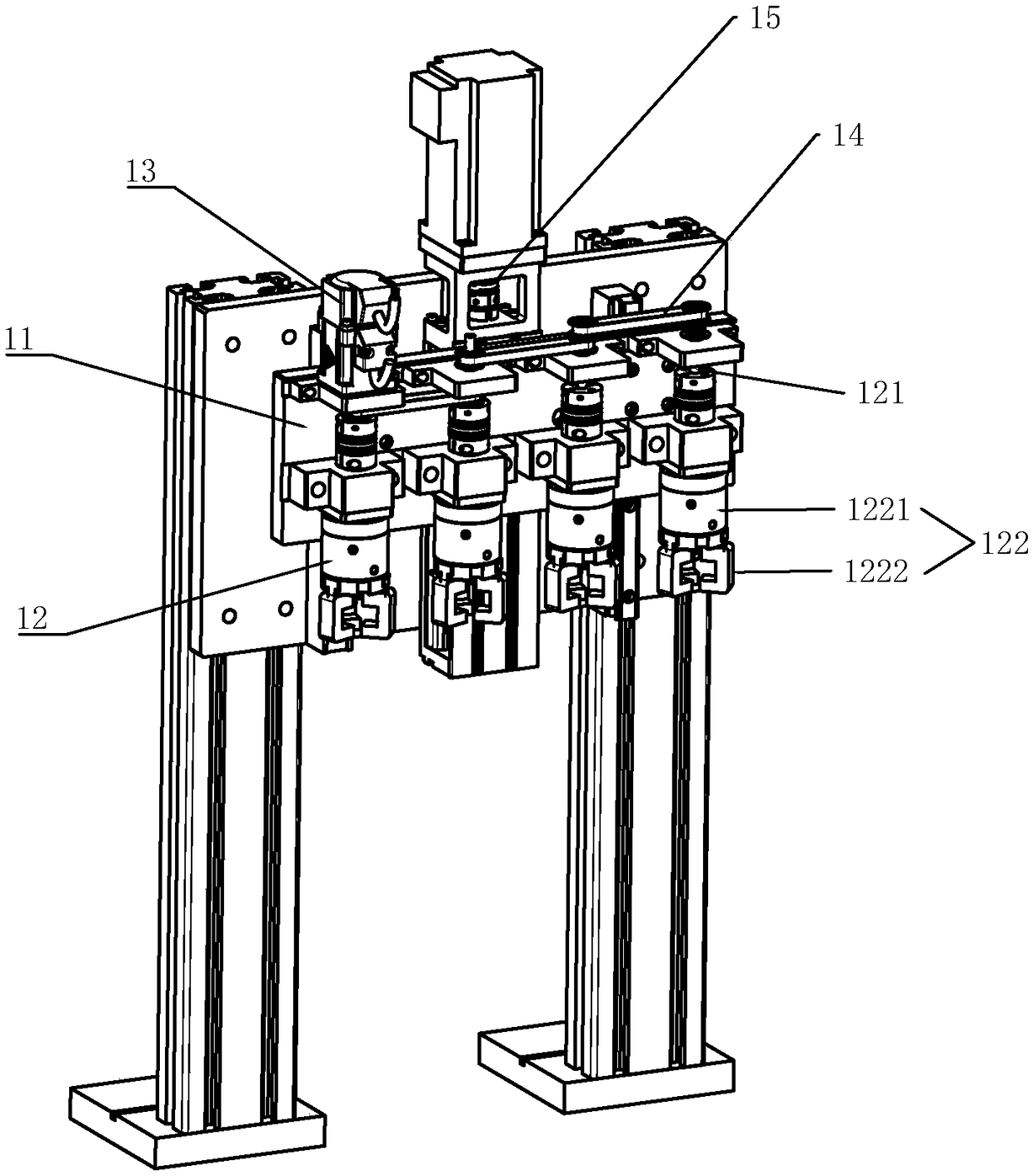

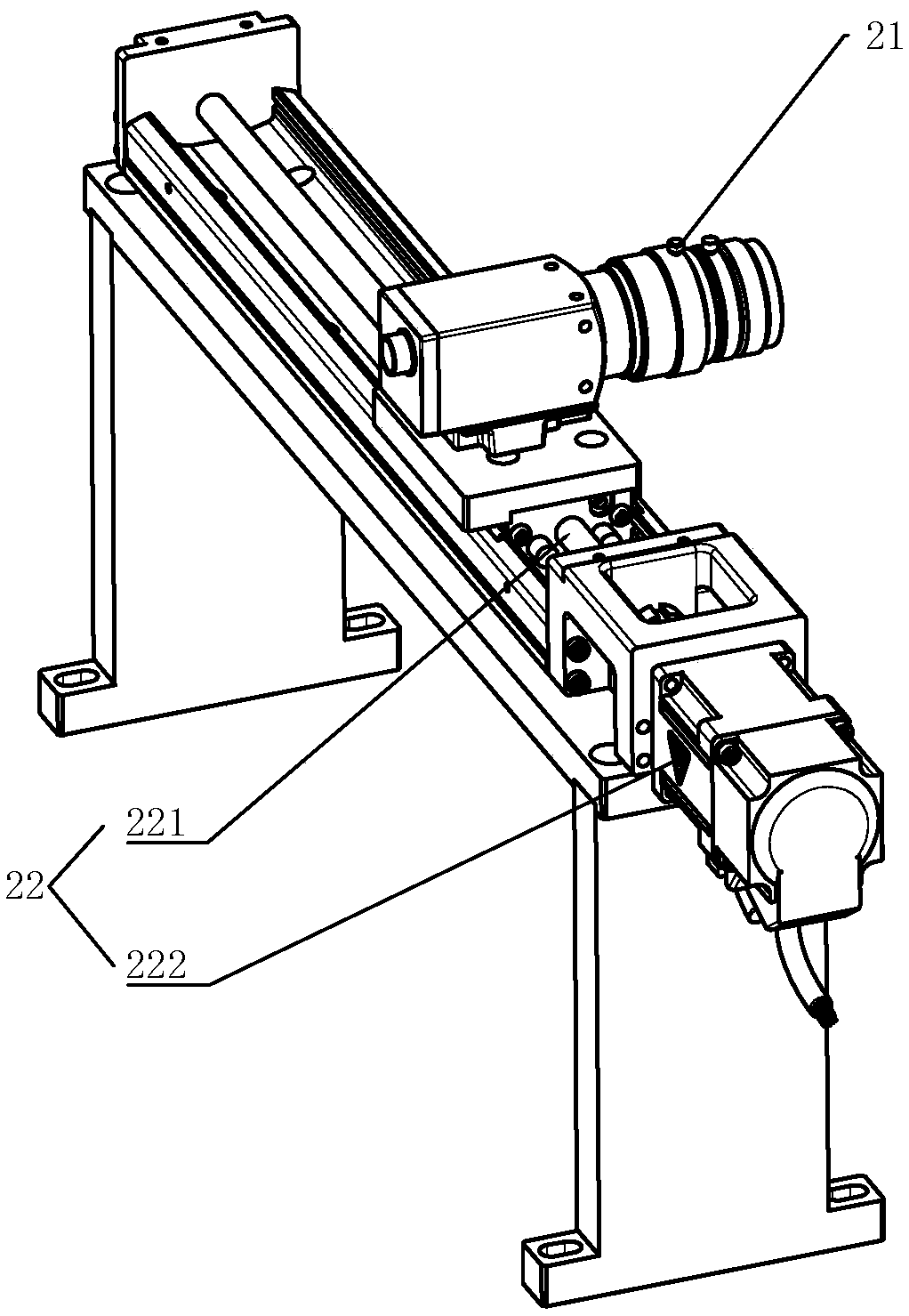

[0022] refer to Figures 1 to 4 , a cosmetic brush accurate and efficient automatic detection and sorting system of the present invention includes a cosmetic brush rotation module 1, a visual detection module 2, a sorting module 3 and a controller module; the cosmetic brush rotation module 1 includes a mounting plate 11. Rotate the first clamping device 12 connected to the mounting plate 11, and the rotary drive device 13 that drives the rotation of the first clamping device 12; the visual inspection module 2 includes a lens facing the first clamping device The camera device 21 on one side of the holding device 12; the sorting module 3 includes a manipulator 31 adjacent to the first holding device 12 and a second holding device 32, and the second holding device 32 is connected to the The hand of the manipulator 31 ; the first clamping device 12 , the rotating drive device 13 , the camera device 21 , the manipulator 31 and the second clamping device 32 are all electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com