Sealing cover of reaction kettle

A technology of sealing cover and reaction kettle, applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., capable of solving the problem of limiting bosses, screws and lock nuts Problems such as damage, limit boss, screw rod and lock nut have a large reaction force, and the sealing effect is not very good, so as to achieve the effect of stable pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

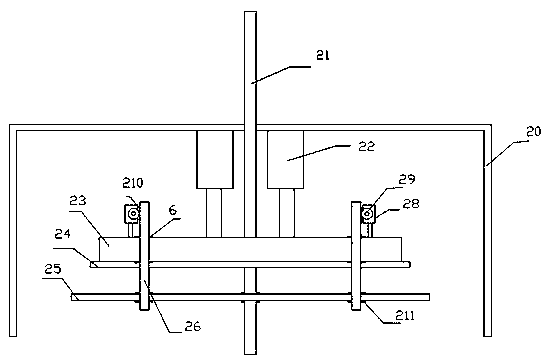

[0035] The sealing cover 2 provided in this embodiment includes a door-shaped bracket 20, a guide rod 21, a cylinder A22, a cover body 23, a flexible sealing ring A24, a flexible sealing plate 25, a guide post 26 and a guide post driving mechanism, and the door-shaped support 20 Welded on the top of the kettle body 1, the door-shaped bracket 20 spans on the opening 27 at the top of the kettle body, the guide rod 21 is installed on the door-shaped bracket 20 through a guide sleeve, and the base of the cylinder A22 is installed on the door-shaped bracket 20, The ejector rod of the cylinder A22 is connected to the cover body 23. Under the action of the cylinder A22, the guide rod 21 can slide up and down in the guide sleeve, and the guide rod 21 passes through the cover body 23 and the flexible sealing ring A24 sequentially from top to bottom. And the flexible sealing plate 25, the cover body 23 is sealed and fixedly connected on the guide rod 21, the flexible sealing ring A24 is ...

Embodiment 2

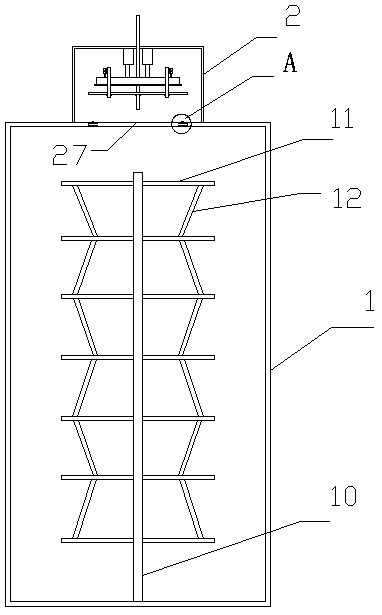

[0043] This embodiment is a specific description of the reaction kettle formed after the sealing cover provided by the present invention is installed on the kettle body of the reaction kettle.

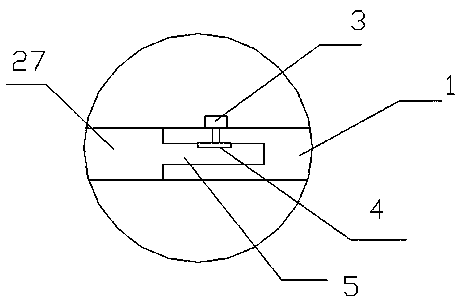

[0044] The top of the still body 1 is provided with a sealing cover, and the top of the still body is provided with a kettle body top opening 27, and the door-shaped support is welded on the still body 1 top, and the door-shaped support 20 is straddled on the opening 27 of the still body top, so The opening 27 of the kettle body top is provided with an annular inner groove 5, the outer diameter of the annular inner groove 5 is greater than or equal to the diameter of the flexible sealing plate 25, and the height of the annular inner groove 5 is greater than the thickness of the flexible sealing plate 25, so Described kettle body 1 top is also equipped with more than four cylinders B3, and cylinder B3 base is fixed on kettle body 1 top, and cylinder B3 ejector pin is connected with an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com