Energy-saving and optimized mixing equipment

A technology of mixing equipment and sleeves, which is applied in the direction of mixers, mixing methods, fluid mixers, etc., and can solve problems such as limited mixing range, no turbulent flow, and unsatisfactory mixing effect between liquid materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

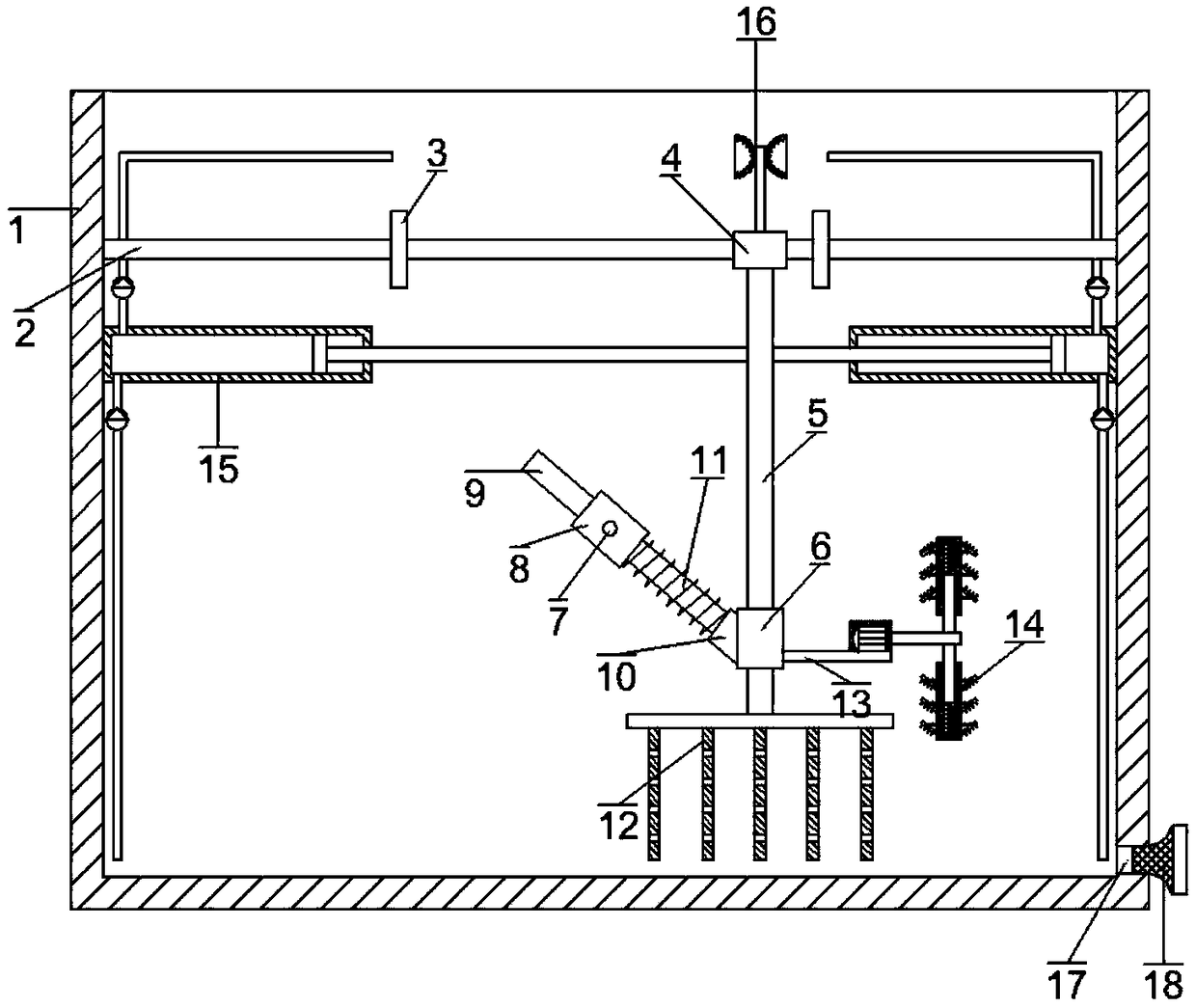

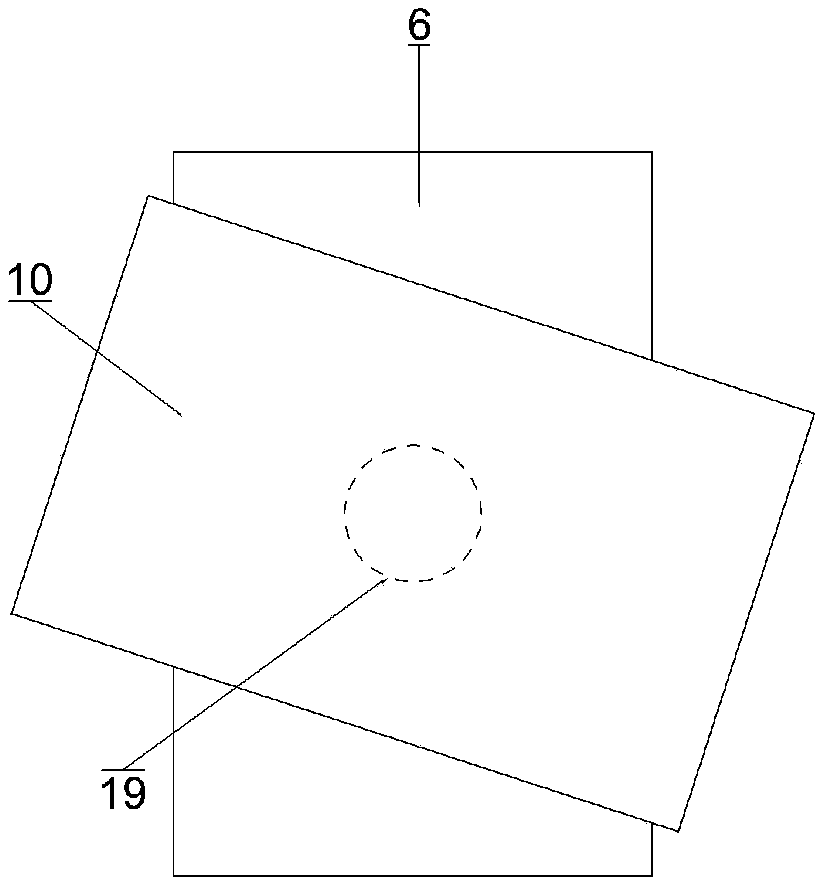

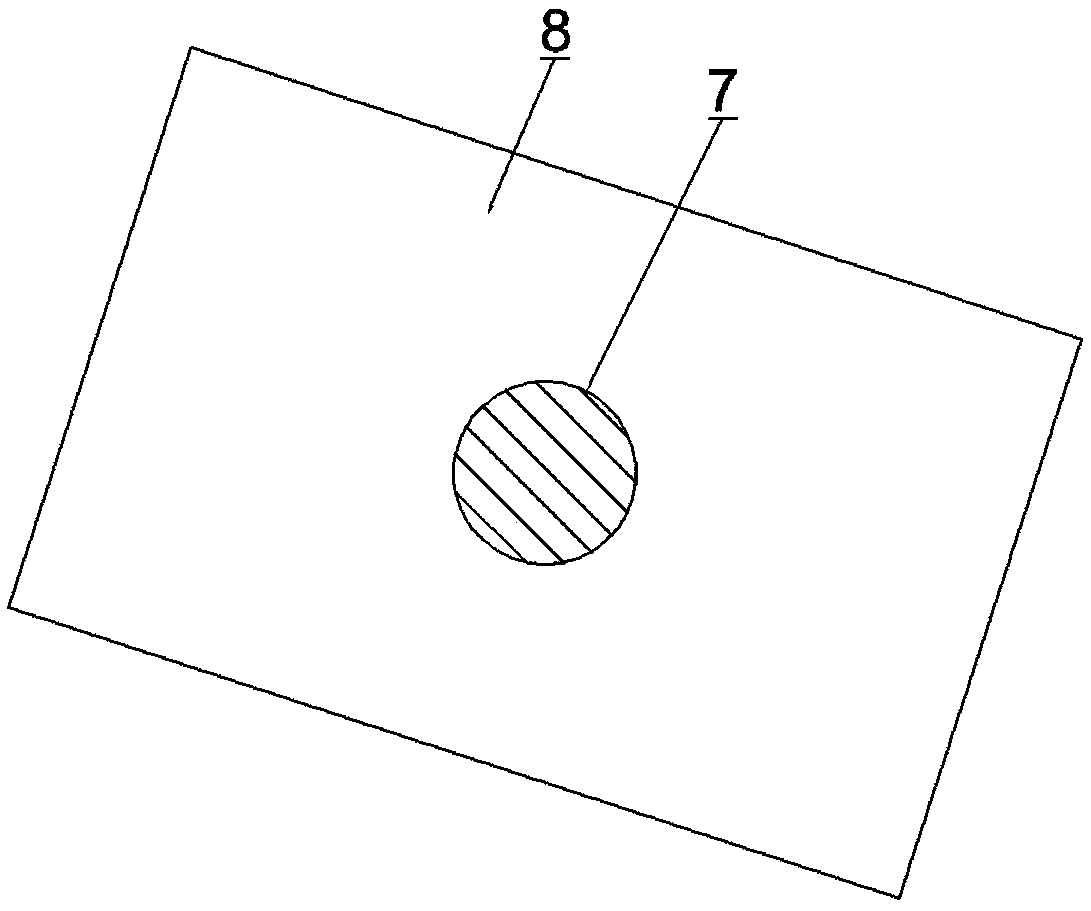

[0032] see figure 1 , figure 2 and image 3 , in this embodiment, an energy-saving optimization mixing equipment, including a housing 1, the top of the housing 1 is open, the inner wall of the upper part of the housing 1 is fixedly connected with a mobile installation column 2, the mobile installation column 2 There are two limit baffles 3 fixedly connected on the upper symmetry, and the mobile installation column 2 between the two limit baffles 3 is covered with a first sleeve 4, and the lower side of the first sleeve 4 is fixedly connected with a vertical column 5. A second sleeve 6 is sheathed on the outside of the vertical column 5; a first rotating shaft 7 is rotatably connected to the front and rear inner walls of the housing 1 below the mobile mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com