Parallel Centrifugal Fan

A centrifugal fan and machine base technology, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of ordinary centrifugal fan axial length limit, low efficiency, large pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with accompanying drawing.

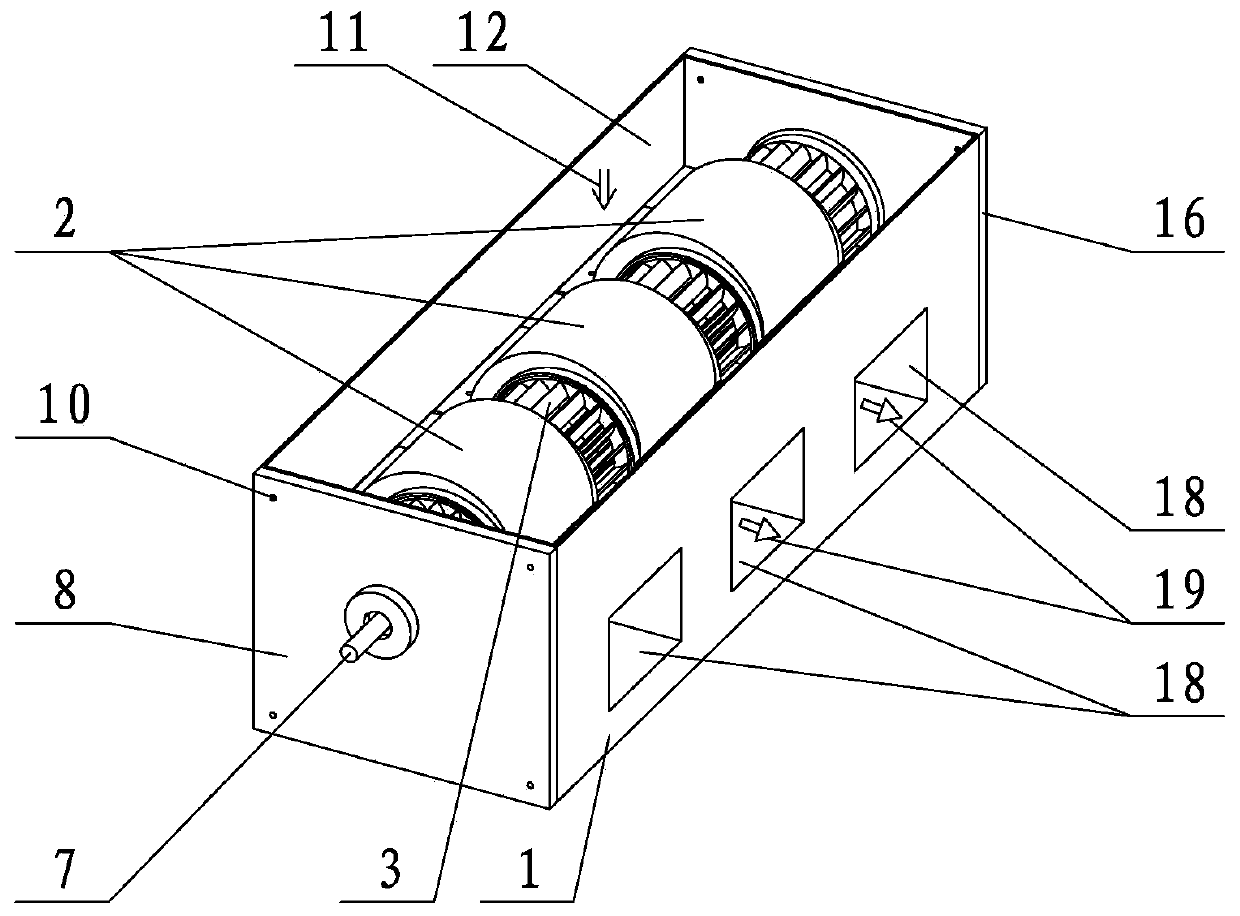

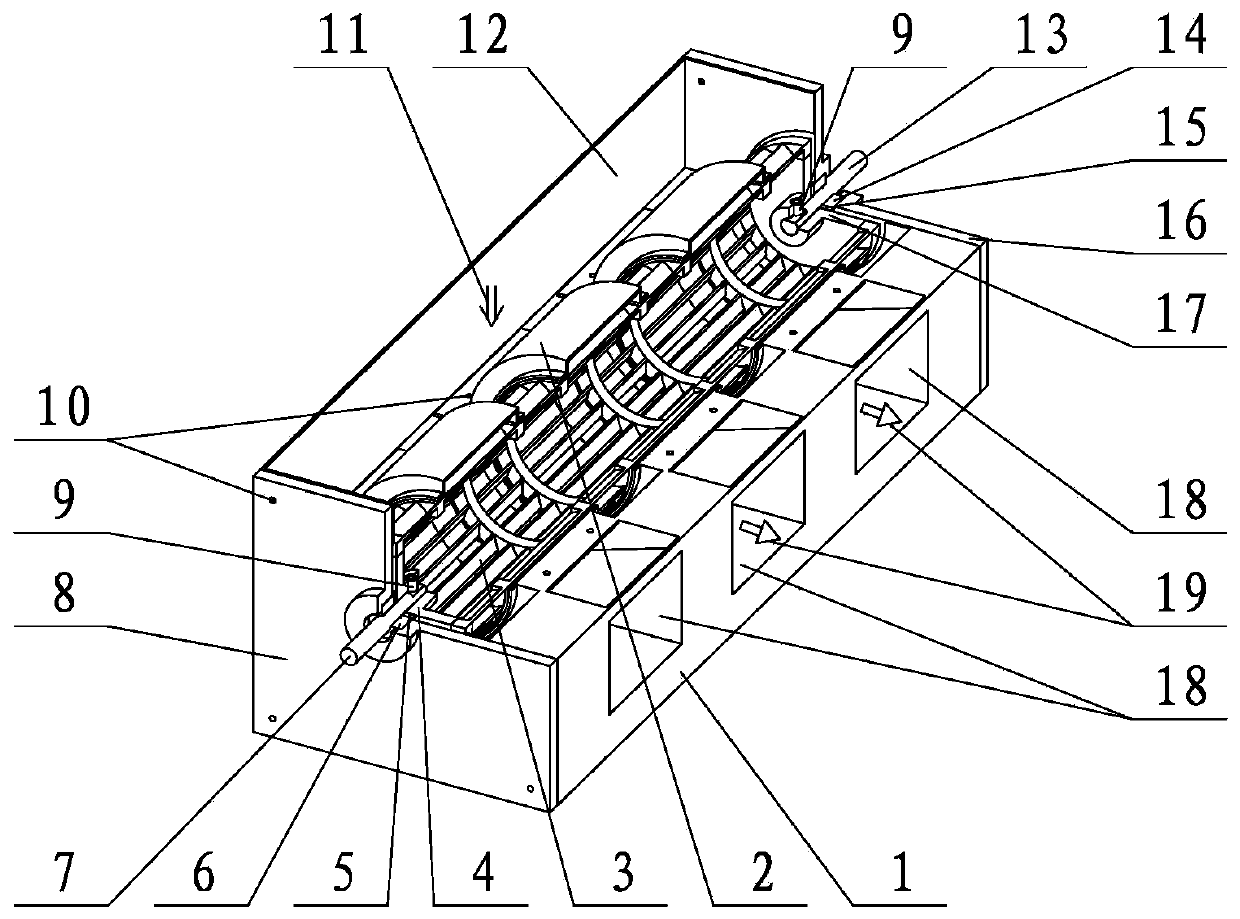

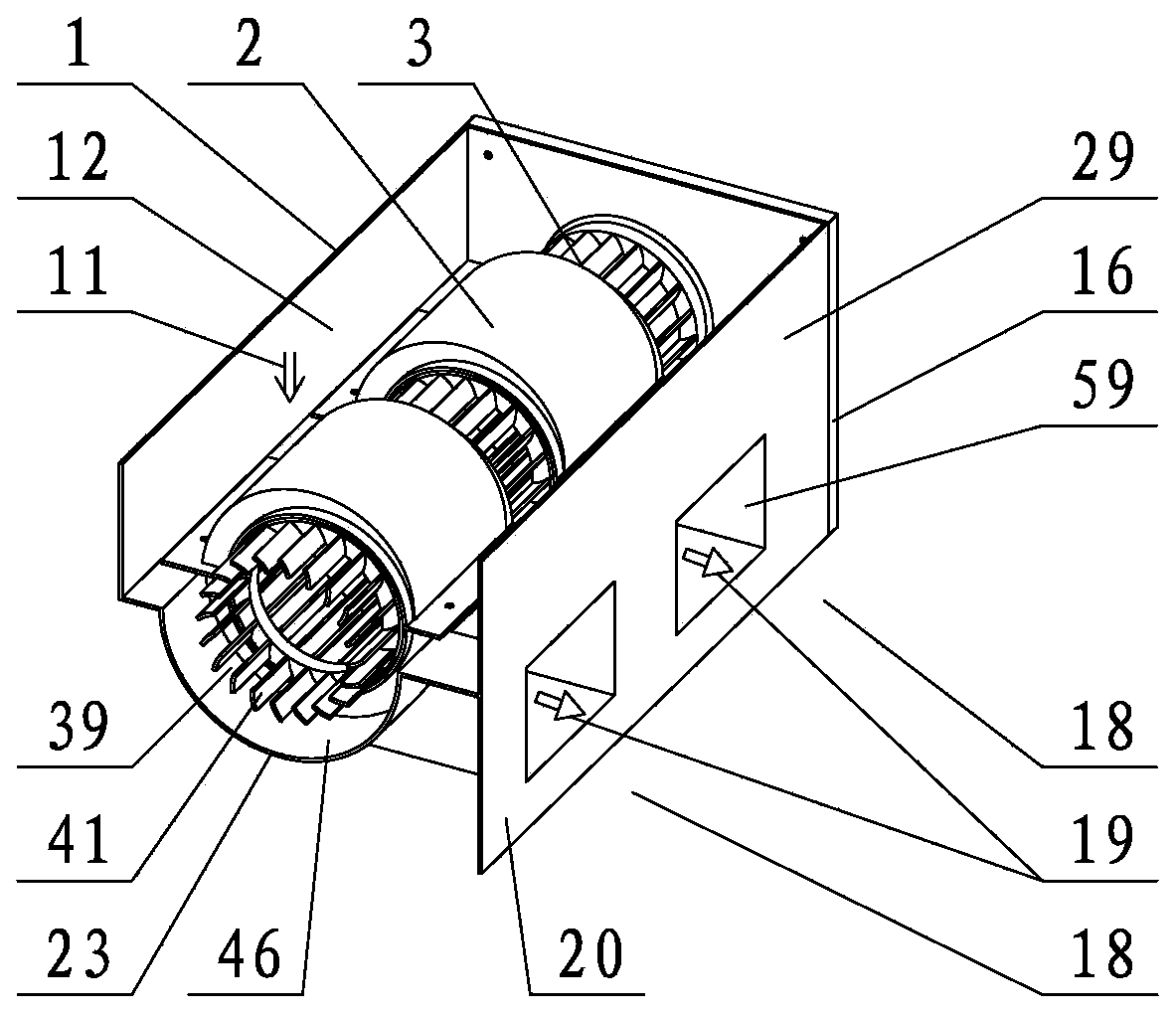

[0041] refer to figure 1 , figure 2 , Figure 18 , Figure 19 , The centrifugal fan includes a base part and an impeller part. The impeller part is installed in the inner cavity of the machine base part, and the motor is installed at one axial end of the machine base part. The base 1 of the base component is axially distributed with several confluence volute plates 23 and several centrifugal volute plates 57, and the confluence volute plates 23 and centrifugal volute plates 57 are arranged at intervals along the axial direction. A centrifugal volute inner cavity 59 is formed between the centrifugal guide volute 2 of several machine base components and the centrifugal volute plate 1 57 of the machine base 1, and the confluence volute plate 23 of the machine base 1 radially inwardly forms the inner cavity of the confluence volute. Cavity 46. The confluence volute inner cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com