Automatic door plate wiping device

A technology for automatic wiping and door panels, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problems of high labor intensity, poor wiping effect, and low wiping efficiency, and achieve The wiping effect is good, the structure is reliable, and the wiping effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

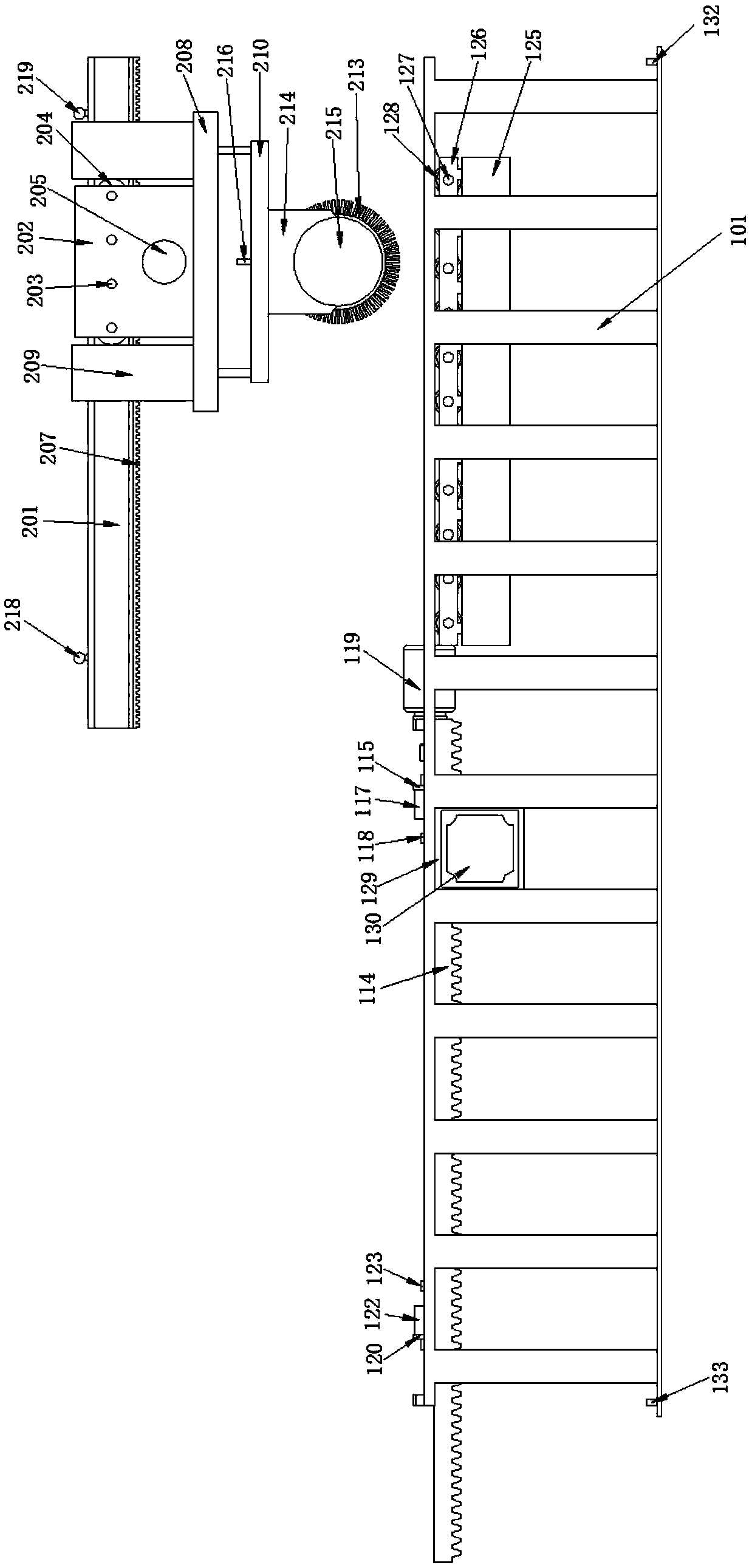

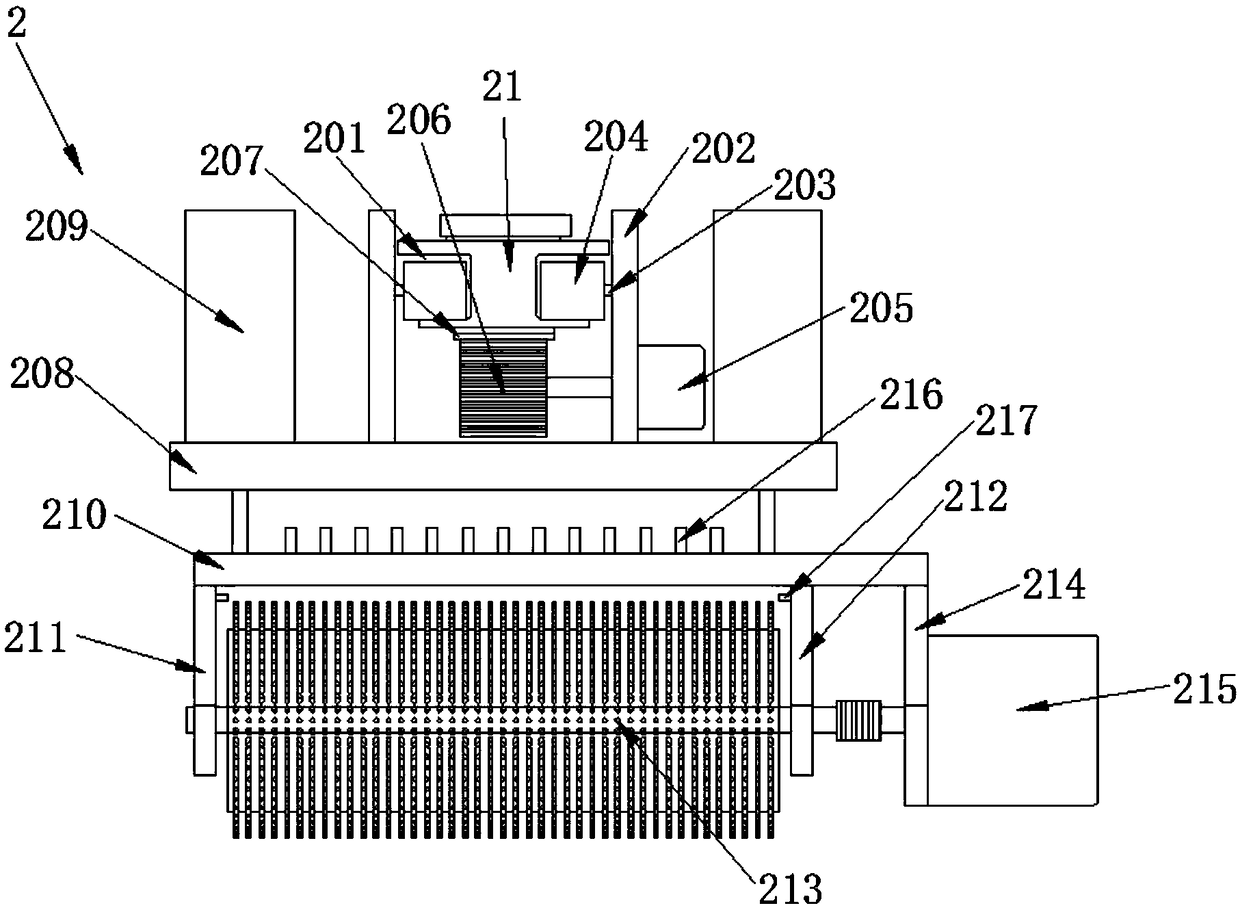

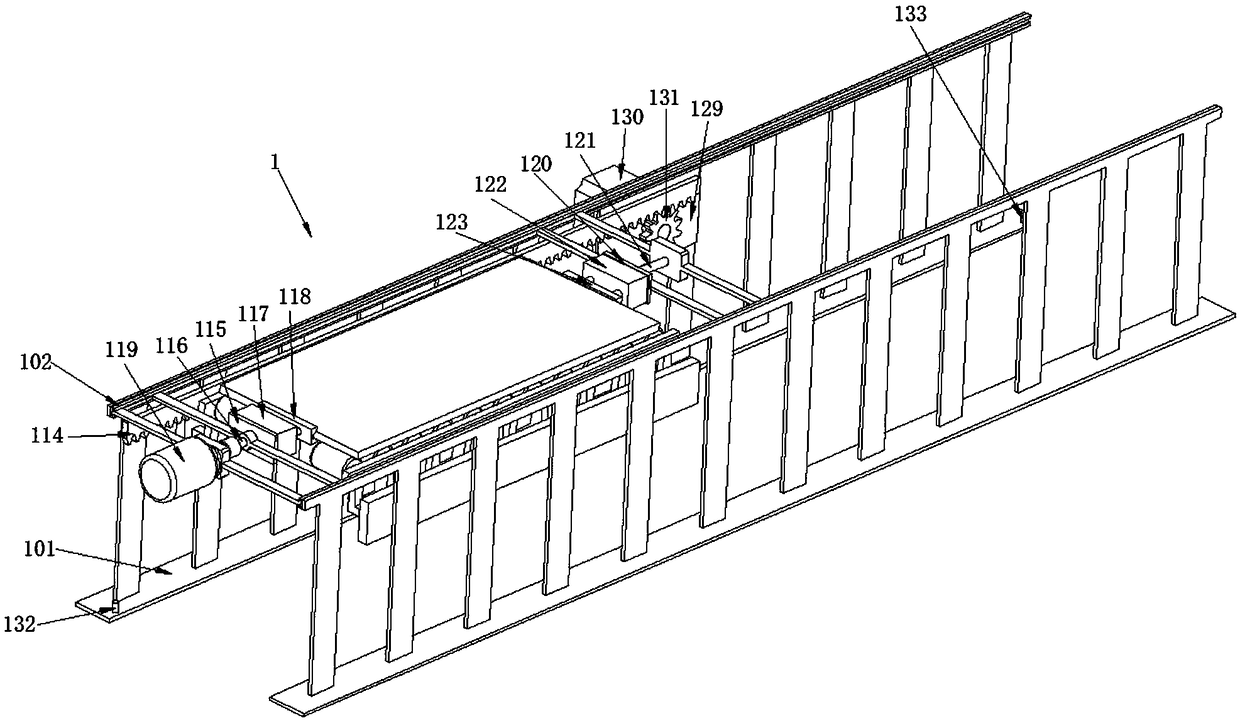

[0018] refer to Figure 1-Figure 5 , an automatic door panel wiping device according to the present invention, comprising a transport turning device 1, a second rotating plate 120 and a transport device 2, the two side frames 101 of the transport turning device 1 are arranged oppositely, and one side of the upper end of the side frame 101 is provided with a sliding Guide groove 102, sliding guide bar 104 on both sides of sliding frame 103 is arranged in sliding guiding groove 102; Described sliding frame 103 one end is provided with first cross bar 105 and second cross bar 108 successively, first cross bar 105 middle part is provided with The first mounting plate 106, the first mounting plate 106 is provided with a first through hole 107, the middle part of the second cross bar 108 is provided with a second rotation hole 109; the other end of the sliding frame 103 is provided with a third cross bar 110 and a first Four crossbars 112, the third crossbar 110 middle part is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com