Dual channel supercharging device

A supercharging device and dual-channel technology, applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as complex structure, bulky, unusable, etc., to achieve The structure is simple, the effect of solving space constraints and reducing the probability of air leakage or failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

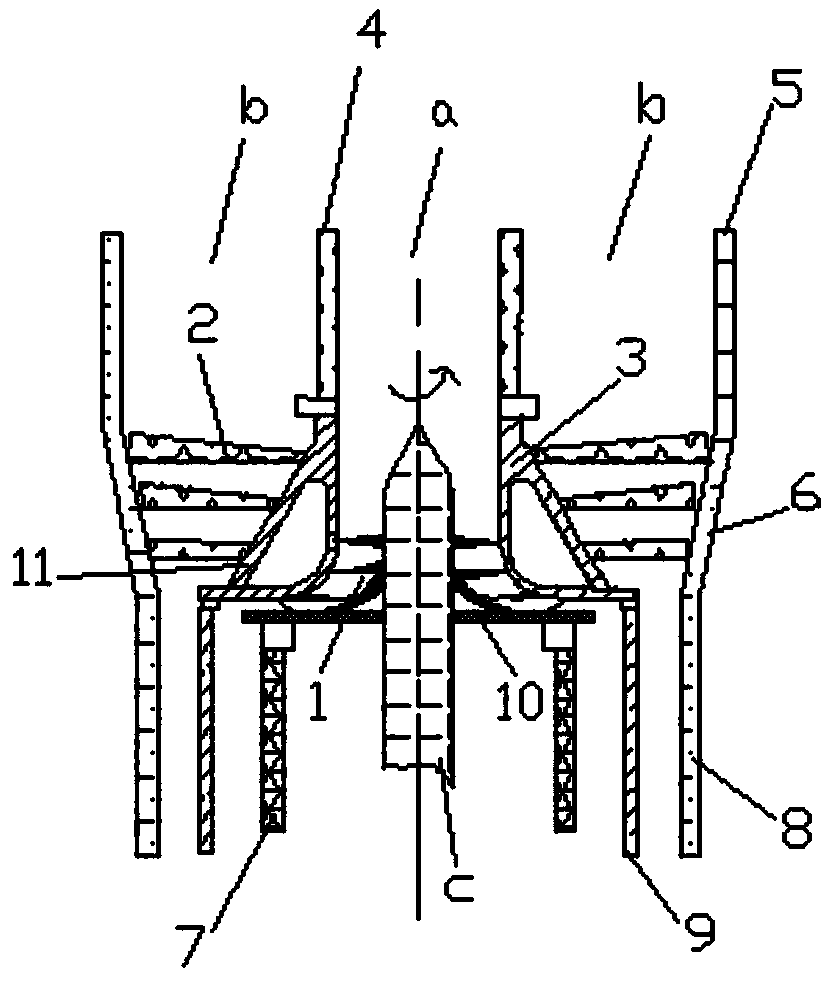

[0019] The present invention is a dual-channel supercharging device, such as figure 1 As shown, it includes the inner channel a and the outer channel b coaxially sleeved together, and the outlet ends of the inner channel a and the outer channel b are located at the same end of the axis, and the inlet ends are located at the other end of the axis, and the corresponding outlet It communicates with the inlet in the axial direction, and the inner channel a and the outer channel b are set as the air intake section and the booster section from front to back in turn. In the intake section and the booster section, the two fluids flow independently; A pressurization part is arranged in the pressurization section of the pressurization part, and the pressurization part pressurizes the fluid passing through the inner channel a and the outer channel b simultaneously. The pressurized part includes a centrifugal impeller 1 for sheathing on the rotor body c. The centrifugal impeller 1 is arra...

Embodiment 2

[0025] A two-channel pressurized device, such as figure 2 As shown, it includes the inner channel a and the outer channel b coaxially sleeved together, and the outlet ends of the inner channel a and the outer channel b are located at the same end of the axis; the inner channel a and the outer channel b are arranged sequentially from front to back Intake section and pressurized section, in the intake section and pressurized section, the two fluids flow independently; in their pressurized section, a pressurized part is arranged, and the pair of pressurized parts passes through the inner channel a and the outer channel b The fluid is pressurized at the same time.

[0026] The above-mentioned pressurized part includes a centrifugal impeller 1 for being sleeved on the rotor body c, and the centrifugal impeller 1 is arranged in the pressurized section of the inner passage, perpendicular to the direction of incoming flow; the outer end of the centrifugal impeller 1 is wound around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com