Gate residue removing device

A technology of residual material and gate, which is applied in the field of gate residual material removal device, can solve the problems of dangerous workers' skills, low efficiency, and excessive dependence, etc., to achieve improved flexibility and convenience, low cost, and safe removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

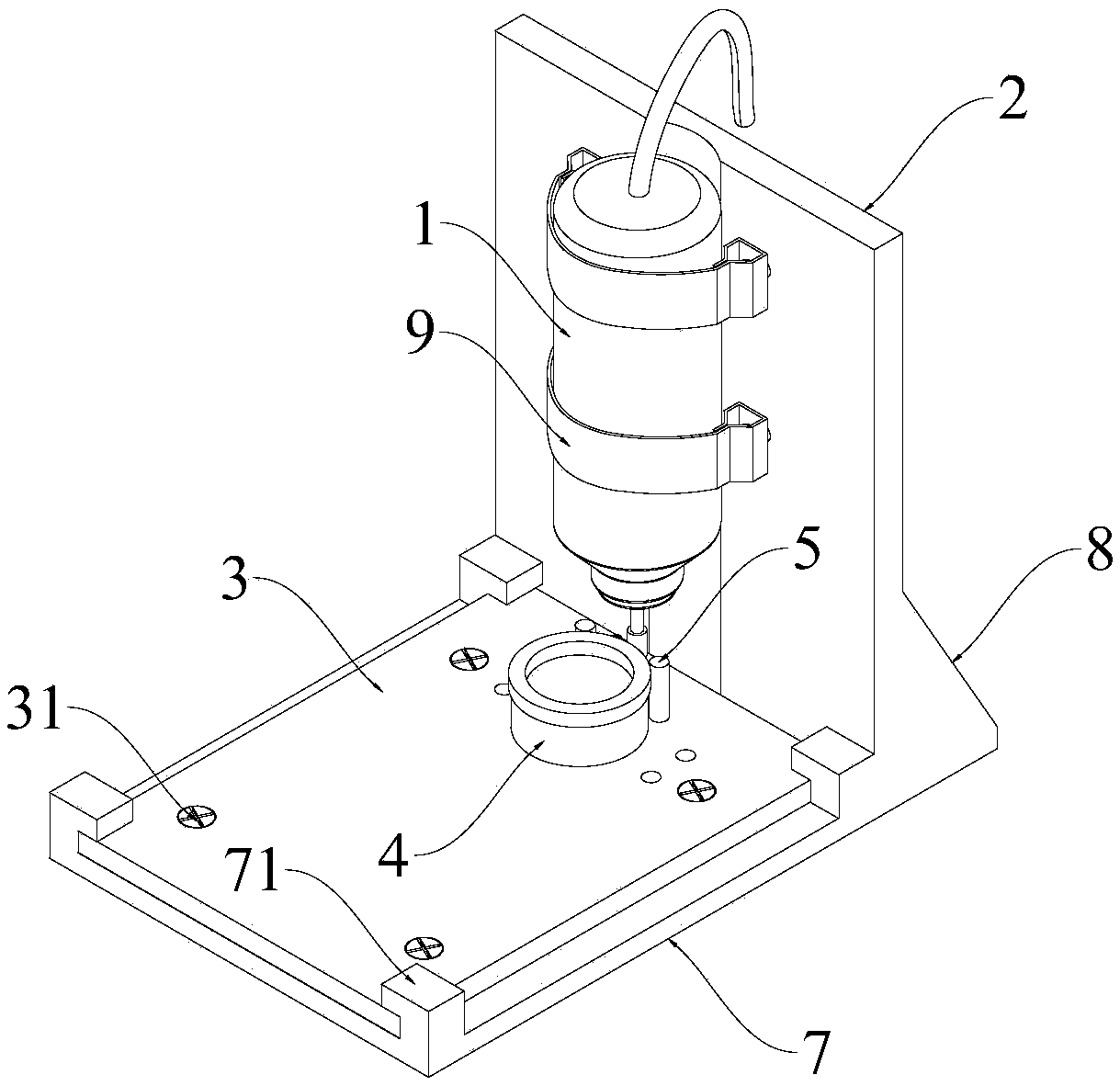

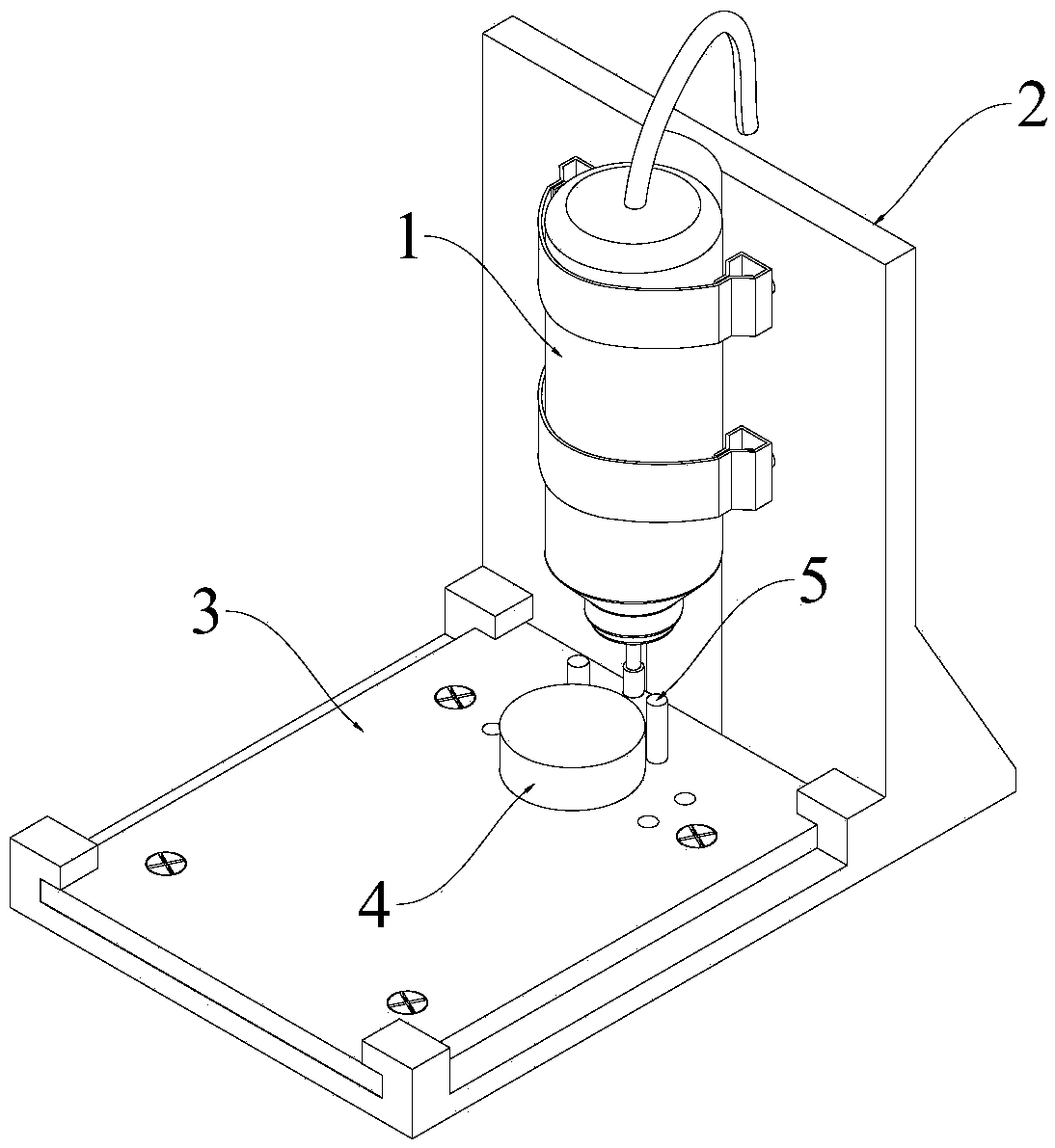

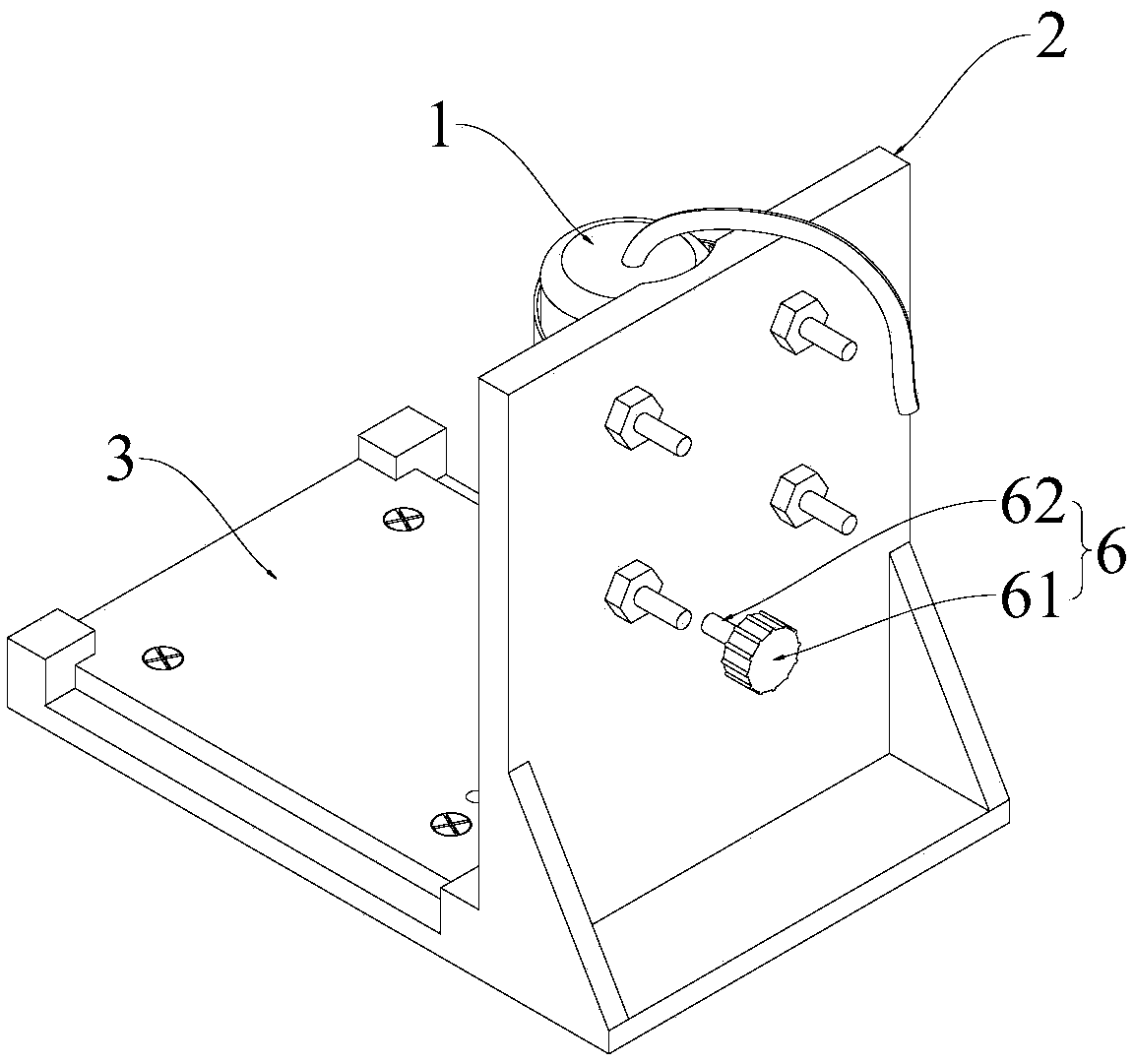

[0033] A gate residue removal device of the present invention will be explained and described in detail below with reference to the accompanying drawings.

[0034] like Figures 1 to 7 As shown in the figure, in order to effectively and quickly remove the gate residual material of the injection molded product, this embodiment specifically discloses a gate residual material rapid removal device, and the removal device includes an electric grinder 1, a bracket 2 and a bottom plate 3 , the electric grinder 1 is fixed on the bracket 2, the base plate 3 is fixed with an operation table 4 and a plurality of limit posts 5, and the operation table 4 has an upper surface for placing the workpiece to be processed, such as figure 1 As shown in , this embodiment provides a ring-shaped workpiece placed on the upper surface of the operating table 4, the workpiece to be processed abuts against the side surfaces of at least two limit posts 5 at the same time, and the grinding head of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com