Modularization storage rack

A modular and shelf technology, which is applied in the field of shelf applications and modular shelves, can solve the problems of low cargo capacity, poor stability, and cargo drop, and achieve the effects of convenient operation, universality, and drop prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

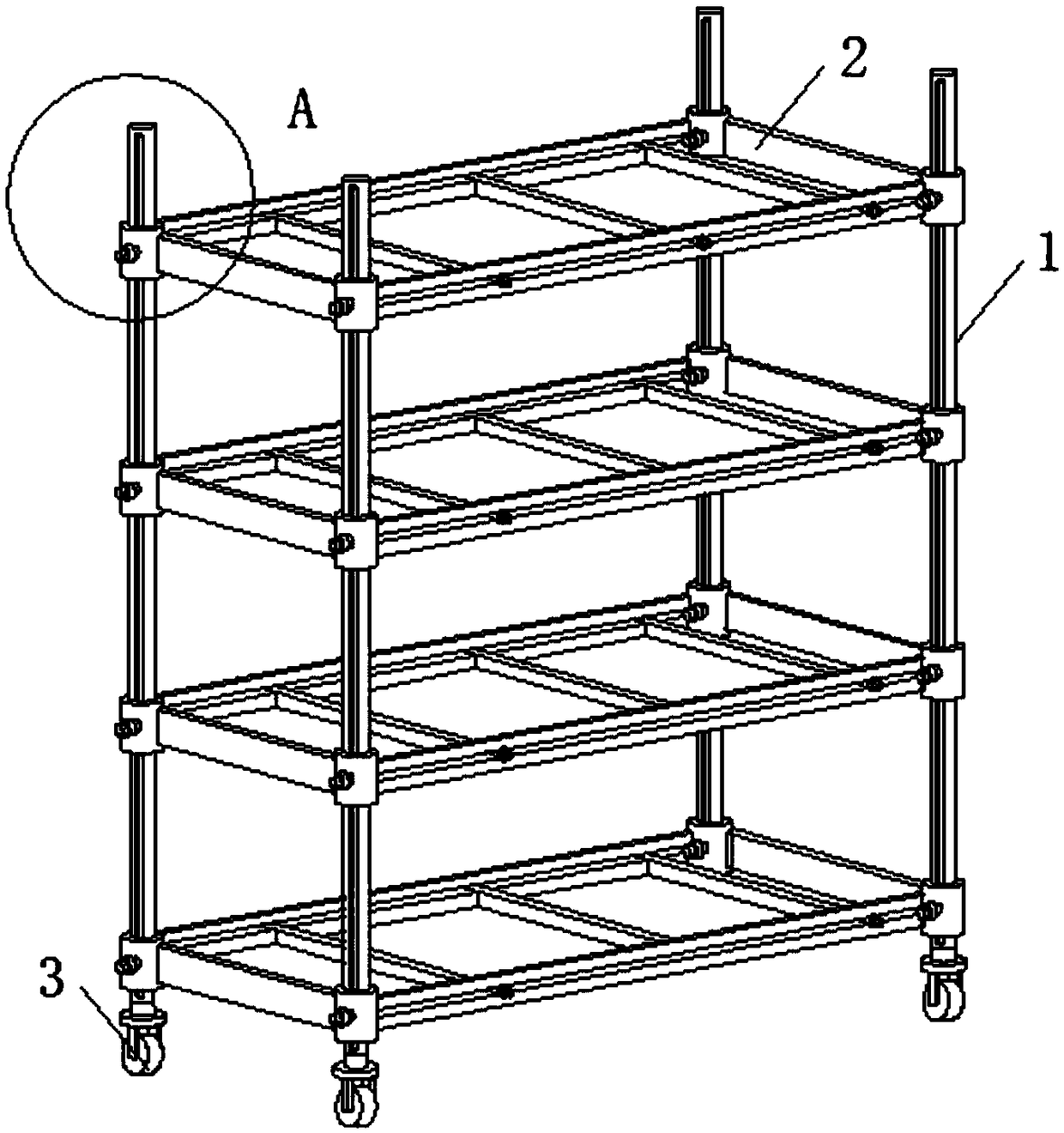

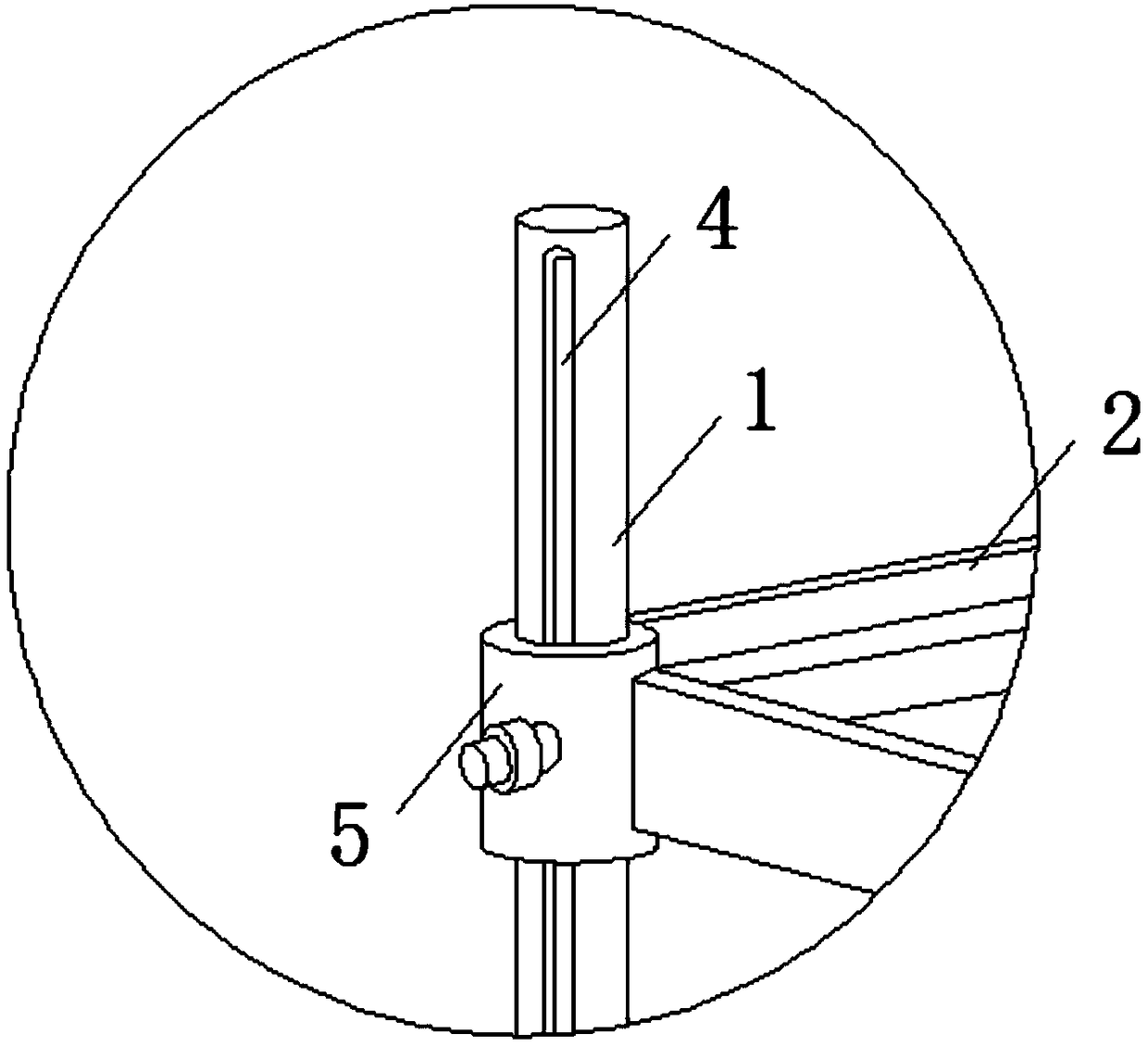

[0022] see Figure 1-6 As shown, the modularized shelf includes a supporting column 1, a pallet 2 and a roller 3, and the four corners of the pallet 2 are installed with supporting columns 1, and four supporting columns 1 are provided with four pallets 2, Rollers 3 are installed at the bottom of the four supporting columns 1, through which the operator can move the shelf. The four supporting columns 1 are all provided with vertical chute 4, and the four corners of the four pallets 2 are provided with socket rings. 5. Both ends of the four pallets 2 are provided with longitudinal baffles 14, both sides of the four pallets 2 are provided with horizontal baffles 10, two horizontal baffles 10 are provided with horizontal chute 11, two Three sliding brackets 13 are stuck between the horizontal chute 11, and the operator slides the hanging posts 15 on the sliding bracket 13 back and forth in the horizontal chute 11, so that the cargo bar 17 on the sliding bracket 13 can carry out th...

Embodiment 2

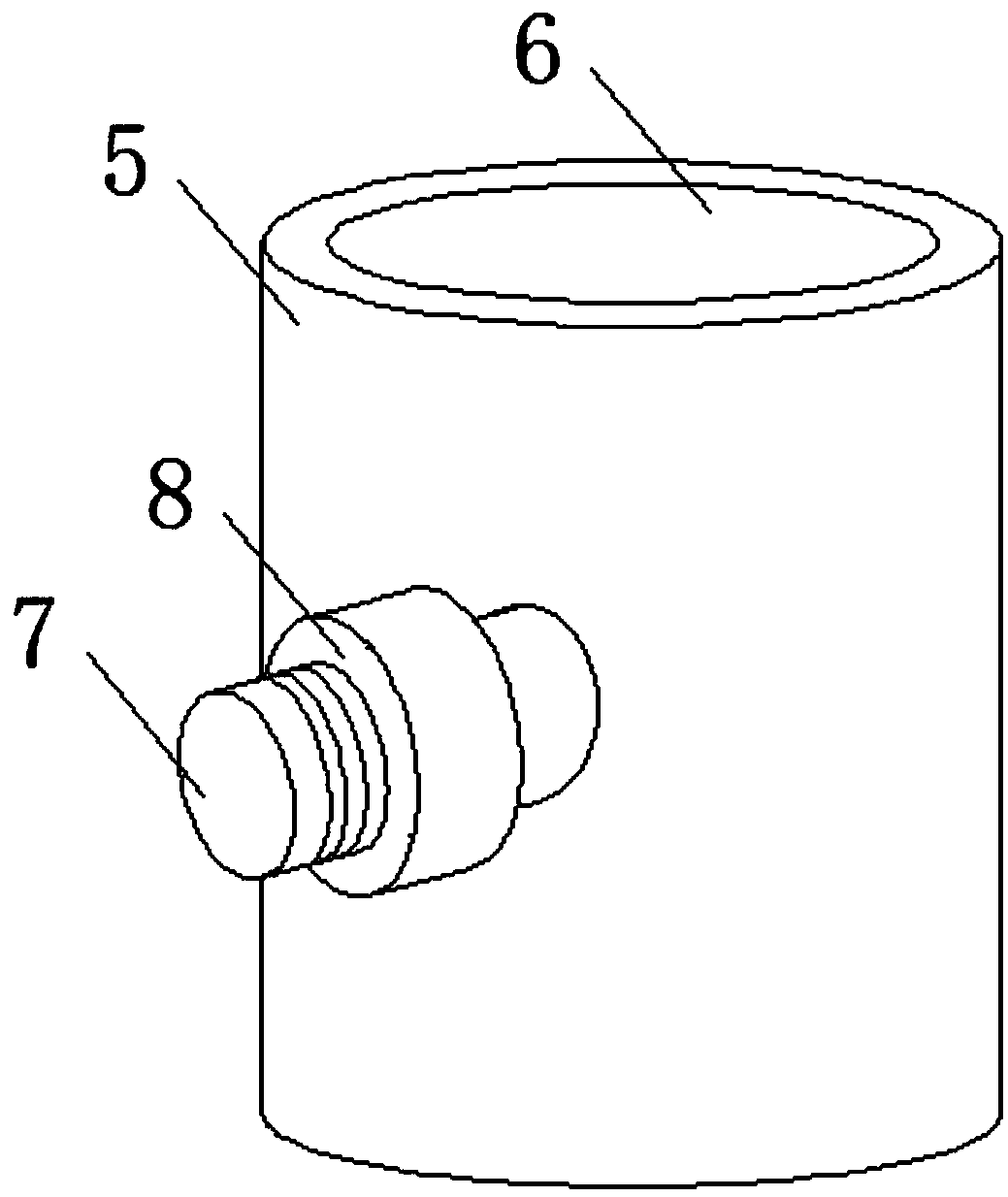

[0024] In addition, please continue to Figure 1-6 As shown, the difference between it and the above-mentioned embodiment is that: the insides of the four sleeve rings 5 are provided with through grooves 6 that match the supporting columns 1, and the four sleeve rings 5 are all equipped with sliding columns 7. By sliding the sliding column 7 up and down in the vertical chute 4, the installation height of the sleeve ring 5 is changed, thereby changing and adjusting the working height of the four pallets 2, which is convenient for the operator to load goods into the pallet 2, and The four sleeve rings 5 are all connected to the inside of the longitudinal chute 4 through the sliding column 7, and the connection between the sliding column 7 and the sleeve ring 5 is installed with a first fixed coil 8, by screwing the first fixed coil 8, The sleeve ring 5 is connected more closely with the supporting column 1 to ensure that the pallet is more stable when loading goods, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com