Integrated forming device and forming method for double-sided complex rib feature structural parts

A technology for rib features and structural parts, which is applied in the field of integrated forming devices for double-sided complex rib feature structural parts, can solve problems such as cracks, cracks in inner ribs, and inability to unscrew double-sided belts, and achieves volume and land occupation. The effect of small area, low manufacturing and maintenance cost, and reduced difficulty in demolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

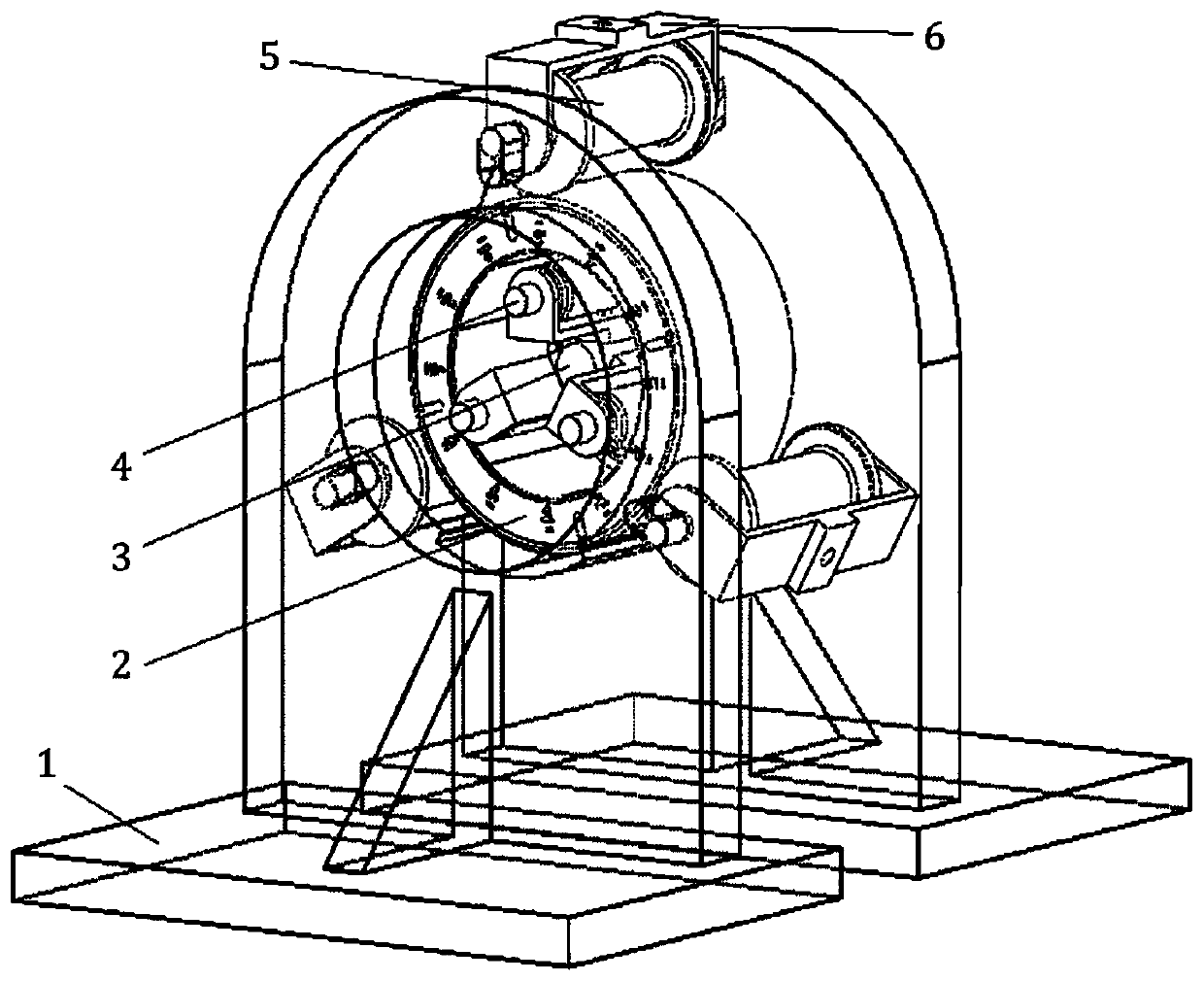

[0032] Such as figure 1 As shown, it is the first loading method of this embodiment. The frame 1 used to fix the roller forming device 2, the support roller 5 and the hydraulic device 3 is divided into two parts, front and rear, wherein: the middle of the front frame is provided for loading and unloading roller forming. Circular hole for device 2.

[0033] At the beginning of the test, it is necessary to set the assembled drum forming device 2 at a fixed position on the frame 1 to complete the pre-positioning of the drum forming device 2, so that the backup roll 5 and the working roll 4 can reach through the hydraulic feeding device 3 The initial processing position, and restrict the axial movement of the roller forming device 2, to ensure that only the inner mold 15 is fed radially during processing.

[0034] After the drum forming device 2 is installed, push the connecting device 6 through the hydraulic system, so that the support roller 5 slowly approaches the drum forming...

Embodiment 2

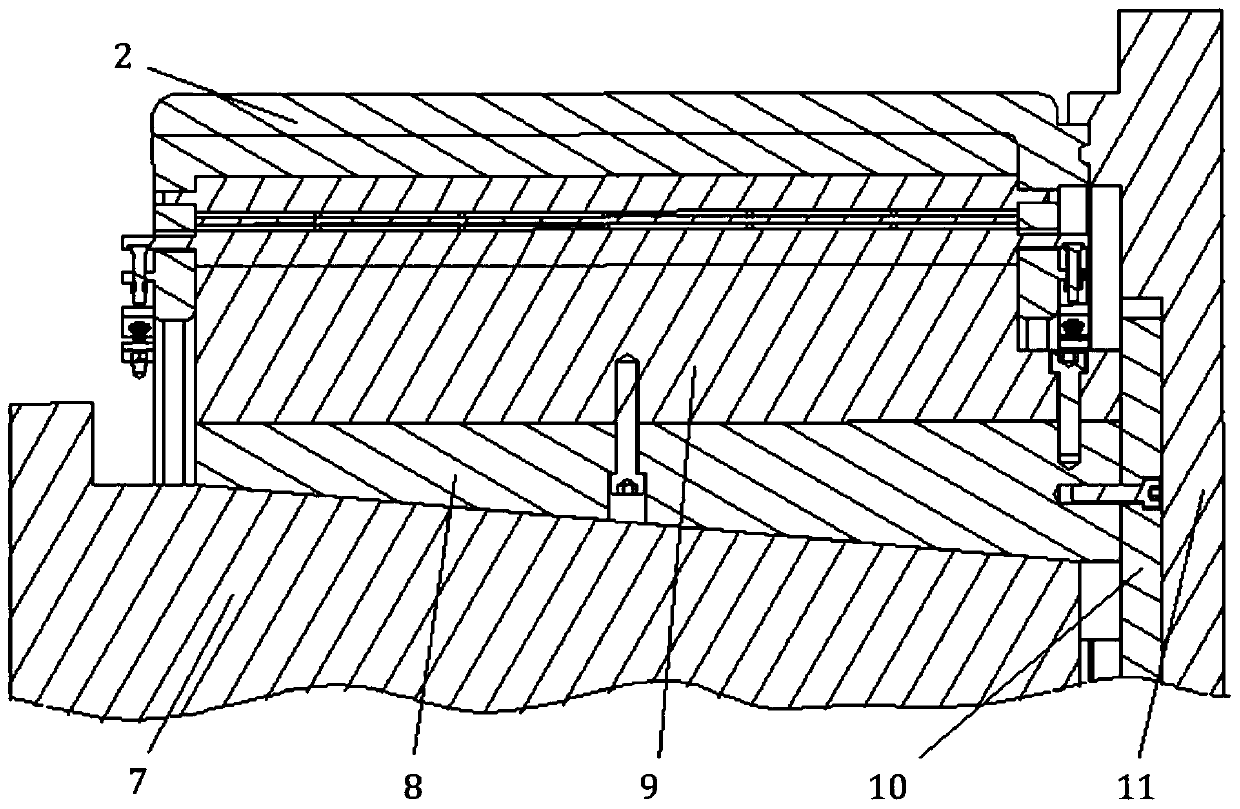

[0038] Such as figure 2 As shown, it is the second loading method of this embodiment. The mold base 11 is set on the working table of the press, and then the wedge block 8, the lower pressing block 9 and the slider 10 are connected by the bolts shown in the figure, and then the The assembled structure is set on the mold base 11, and then the roller forming device 2 is set on the mold base 11, and the inner wall of the roller forming device 2 is closely matched with the lower pressing block 9, and finally the lower pressing shaft 7 is pressed down with the pressing machine. The mechanism is connected, and the pressing speed and pressing pressure of the lower pressing shaft 7 are set to 1mm / min and 300KN respectively through the press. During the traveling process of the lower pressing shaft 7, radial displacement and pressure will be generated on the wedge block 8, pushing the slider at the bottom 10 and the lower pressing block 9 are fed radially to realize the loading on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com