Device for improving wort sampling convenience

A convenience and wort technology, applied in the field of beer, can solve the problems of inconvenient operation, unfavorable parameter measurement, wort spilling, etc., and achieve the effects of reducing labor intensity, preventing wort spilling, and reducing buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

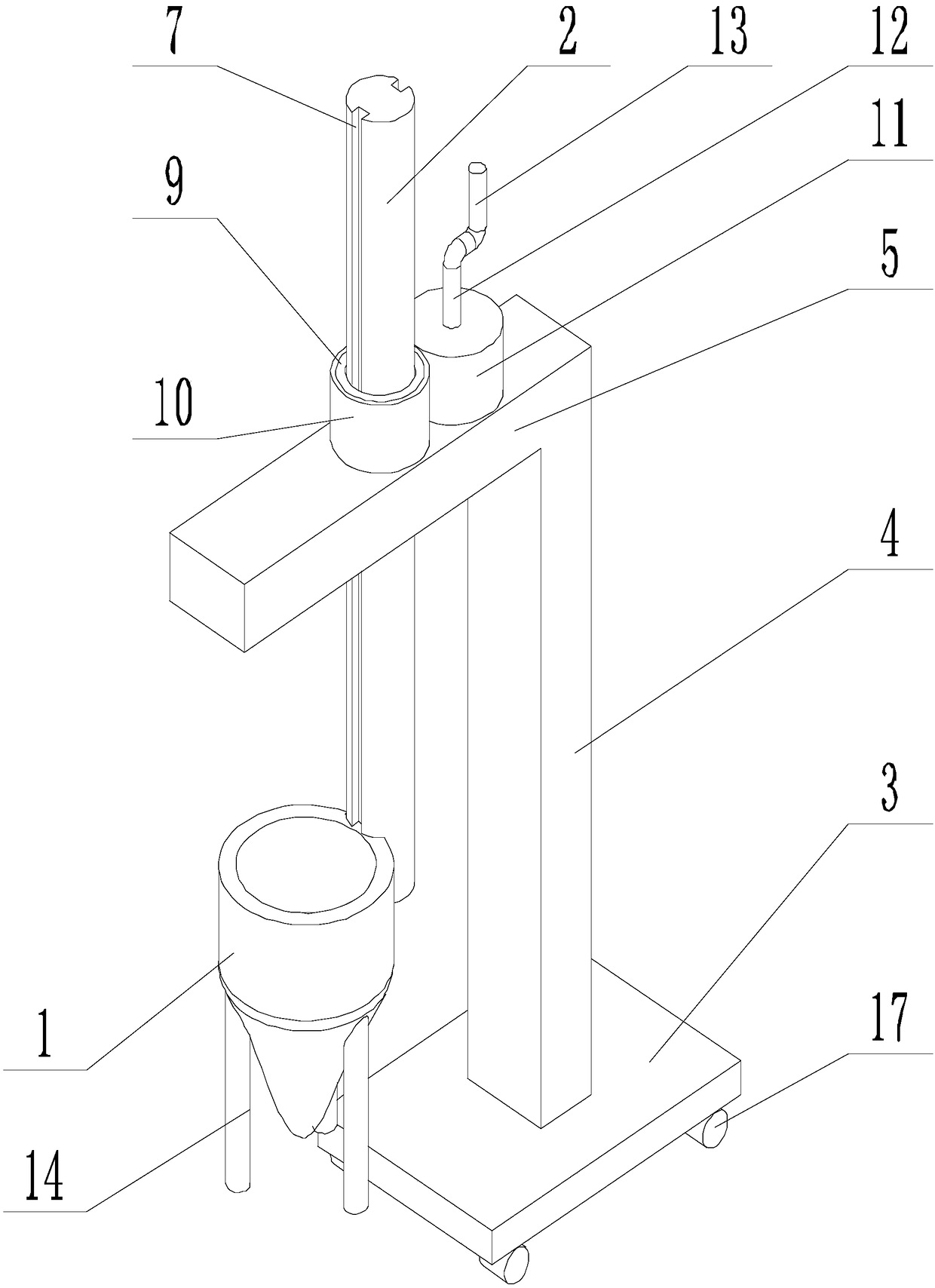

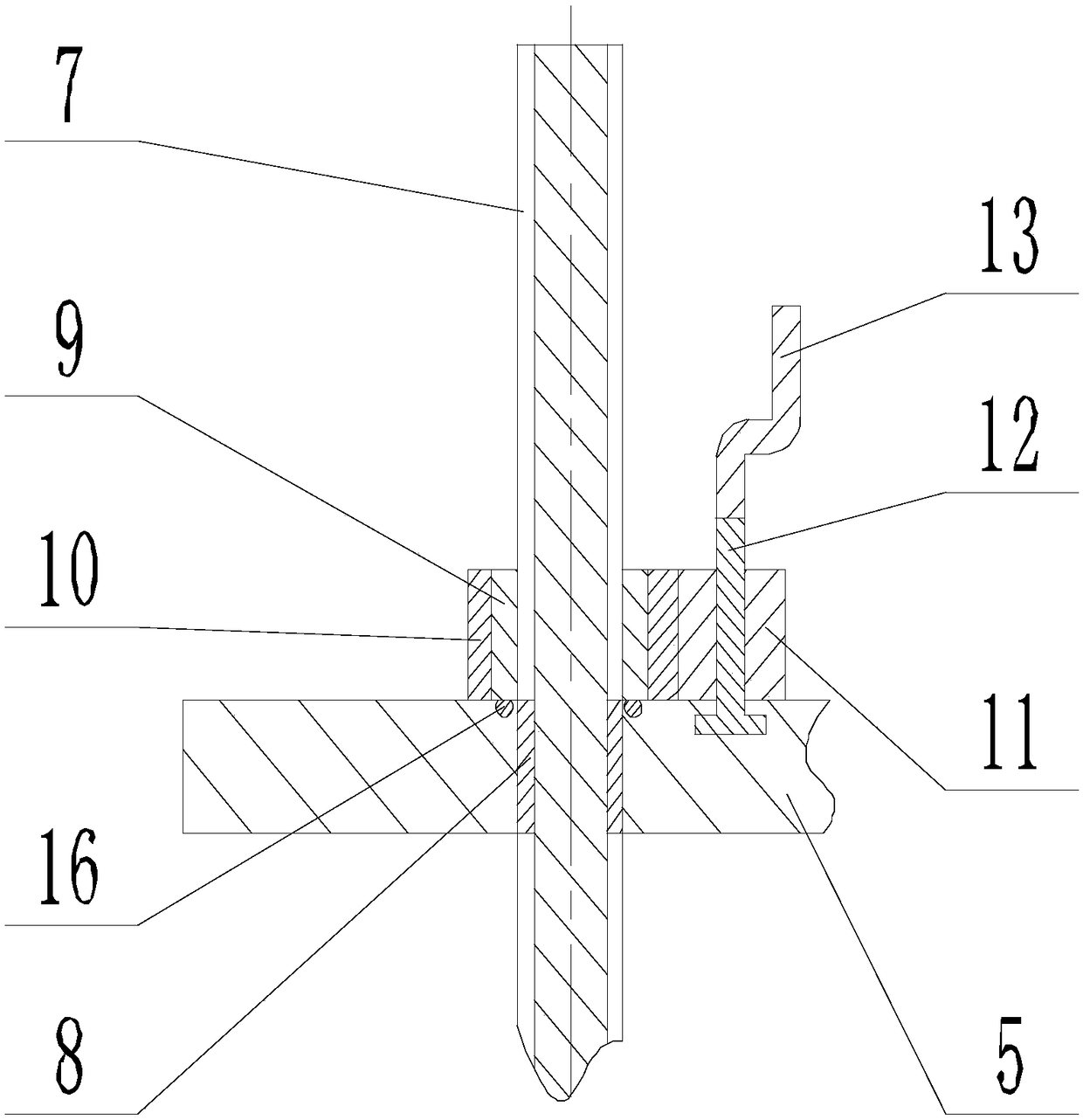

[0024] Such as Figure 1-Figure 4 As shown, the device for improving the convenience of wort sampling according to the present invention includes a supporting device, a drive assembly, and a reclaiming barrel 1 and an extension rod 2 connected in sequence. The supporting device includes a bottom plate 3, a supporting column 4, and a cantilever 5 connected in sequence. The axis of the support column 4 is perpendicular to the bottom plate 3, one end is connected to the upper surface of the bottom plate 3, and the other end is connected to one end of the cantilever 5, and the axis of the cantilever 5 is perpendicular to the axis of the support column 4, and the cantilever 5 A through hole 6 is provided on the through hole 6, and a limit bar 8 is provided on the wall of the through hole 6, the axis of the limit bar 8 is parallel to the axis of the through hole 6, and a nut 9 is provided above the cantilever 5 The axis of 9 coincides with the axis of the through hole 6, the bottom o...

Embodiment 2

[0029] The bottom of the reclaiming barrel 1 protrudes into a conical shape, and a plurality of supporting legs 14 are arranged at the conical part. The axis of the supporting legs 14 is parallel to the axis of the reclaiming barrel 1, and one end is connected to the outer wall of the cone. Connected, the other end face is parallel to the horizontal plane and coplanar with each other.

[0030] Since the bottom of the reclaiming barrel 1 is convex into a conical shape, the buoyancy that the operator needs to overcome when the reclaiming barrel 1 is in contact with the wort liquid surface is reduced, and the labor intensity of the operator is further reduced.

Embodiment 3

[0032] The rotational connection between the nut and the cantilever is achieved by the following technical solution: an annular groove 15 is provided on the upper surface of the cantilever 5, the axis of the annular groove 15 coincides with the axis of the through hole 6, and the cross section of the annular groove 15 is It has an excellent arc shape. A sliding block 16 is provided at the bottom of the nut 9. The sliding block 16 is spherical, the top of which is connected with the nut 9, and the bottom of which is inserted into the annular groove 15 and inscribed on the groove wall of the annular groove 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com