Device for simultaneously detecting straightness of two sides of frame for rectangular frame corner connector automated assembly machinery

A detection device and flatness technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of low efficiency and achieve the effect of high efficiency, small impact, efficient and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and embodiment, but this can not be used for the limitation of the present invention, those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as not departing from the present invention The basic ideas are all within the scope of the present invention.

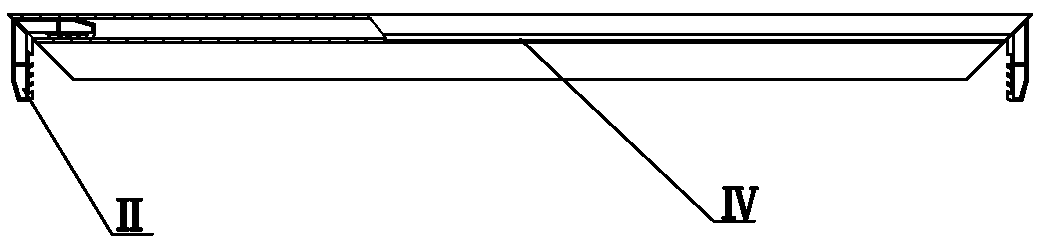

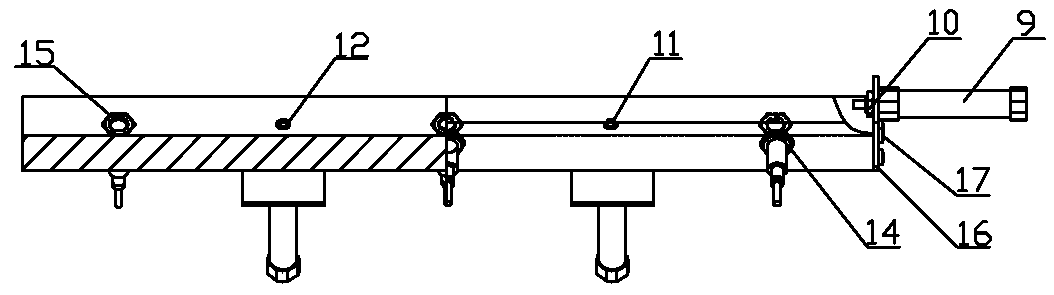

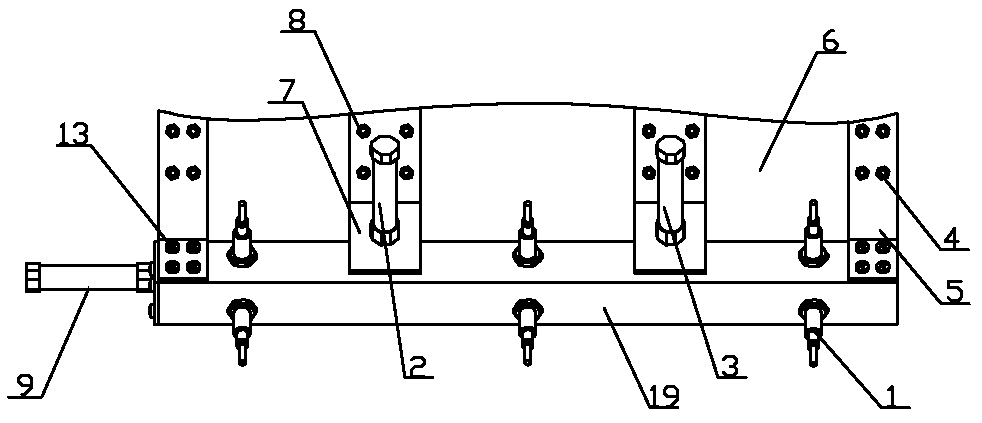

[0024] Such as Figure 2-5 shown.

[0025] A device for simultaneously detecting the straightness of both sides of a frame for a rectangular frame corner code automatic assembly machine, which is mainly composed of a V-shaped groove assembly, a sensor assembly, and a cylinder assembly; wherein, the V-shaped groove assembly consists of a V-shaped groove 19, a V-shaped groove Groove fixing plate 5, fixing bolt 4, fixing screw 13 are formed, as image 3 , the V-shaped groove 19 is connected with two V-shaped groove fixed plates 5 by 4 fixing scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com