Pipeline system of LNG double-gun filling machine

A pipeline system and gas filling pipe technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as crowding of gas filling machine components, inaccurate measurement of mass flow meters, and shortening the service life of pumps, etc. Achieve the effect of facilitating assembly and post-maintenance, saving cost and space, and reducing overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

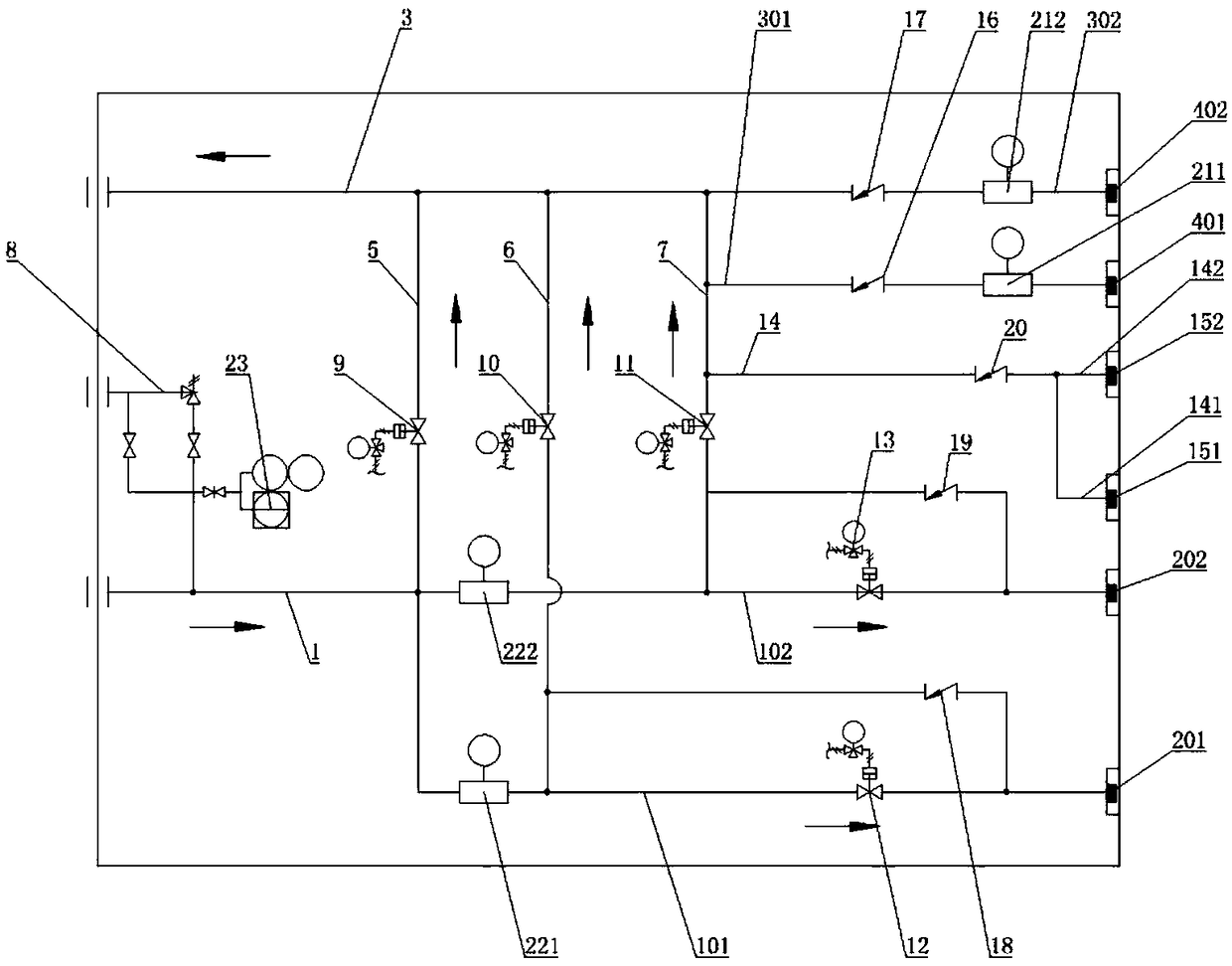

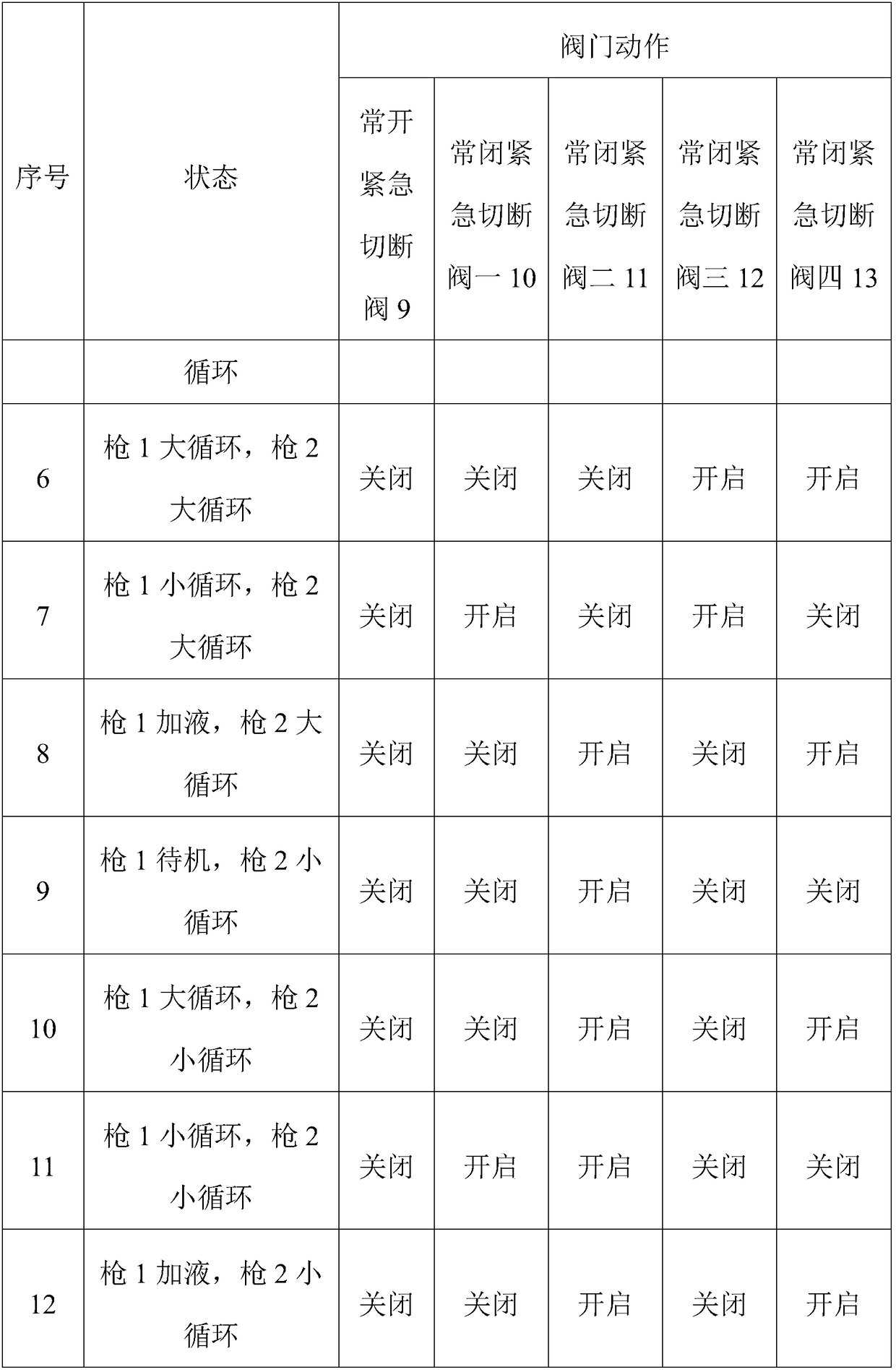

[0023] Such as figure 1 As shown, the direction of the arrow in the figure is the direction of fluid flow when the valve is opened. A pipeline system for LNG double gun filling machine, including gas filling pipeline 1 and gas return pipeline 3, gas filling pipeline 1 includes gas filling pipeline 1 101 and gas filling pipeline 2 102 respectively connected to gas filling gun 1 201 and gas filling gun Two 202, the air return pipeline 3 includes the air return pipeline 1 301 and the air return pipeline 2 302 respectively connected to the air return gun 1 401 and the air return gun 2 402, the system also includes the standby pipeline 5, the small circulation pipeline 1 6, and the small circulation pipe Road 2 7 and safety valve pipeline 8, the safety valve pipeline 8 is connected to the gas filling pipeline 1, a pressure sensor 23 is provided in the safety valve pipeline 8 to monitor the pressure, and the standby pipeline 5 is provided with a normally open emergency shut-off valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com