Buried type hinge structure

A hinged structure, embedded technology, applied in building structures, door/window fittings, wing fan components, etc., can solve the problems of not having a good buffer effect, affecting the life of the buffer, and large collision force of furniture, etc. Improve the user experience, prolong the service life, and avoid the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

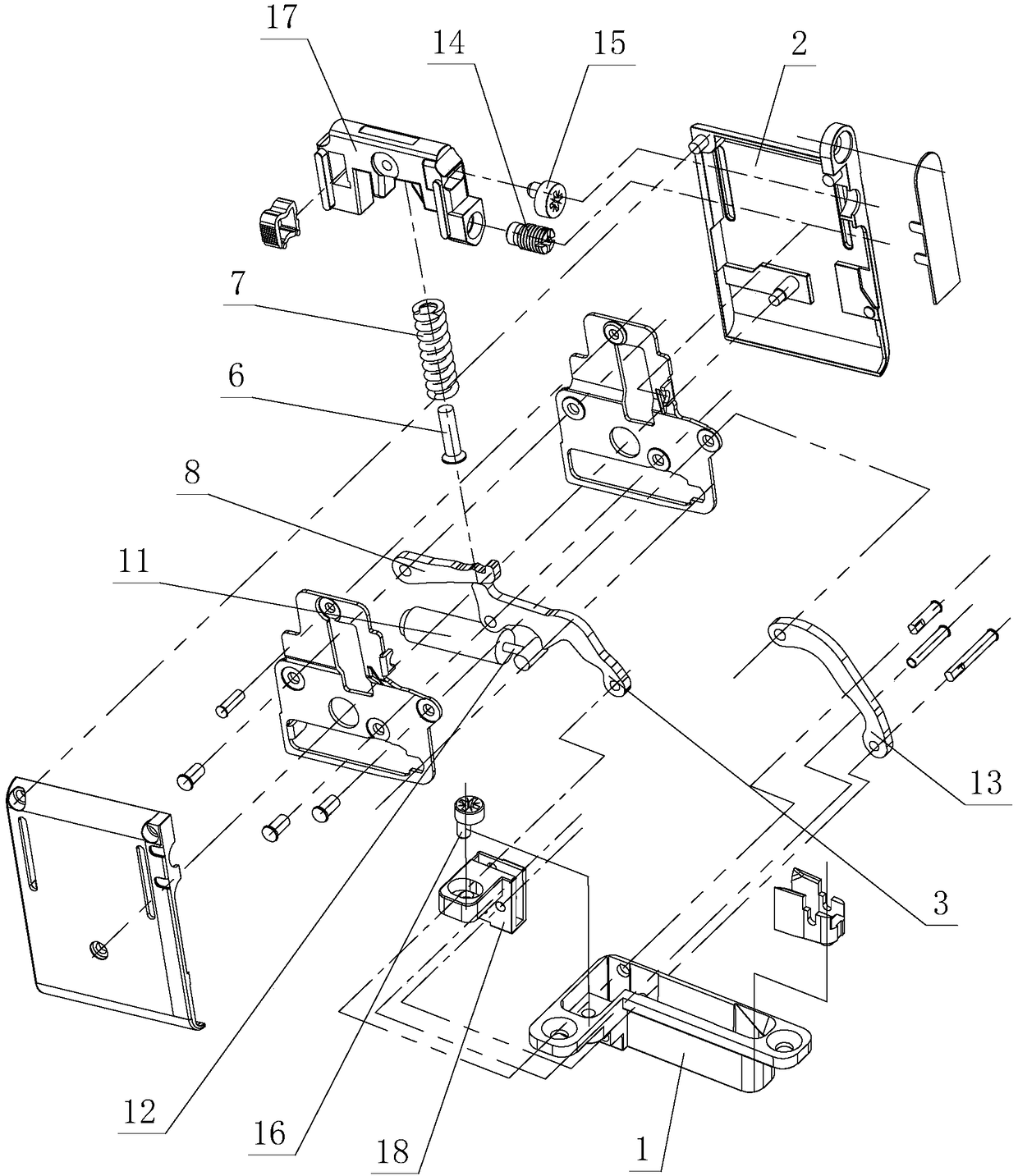

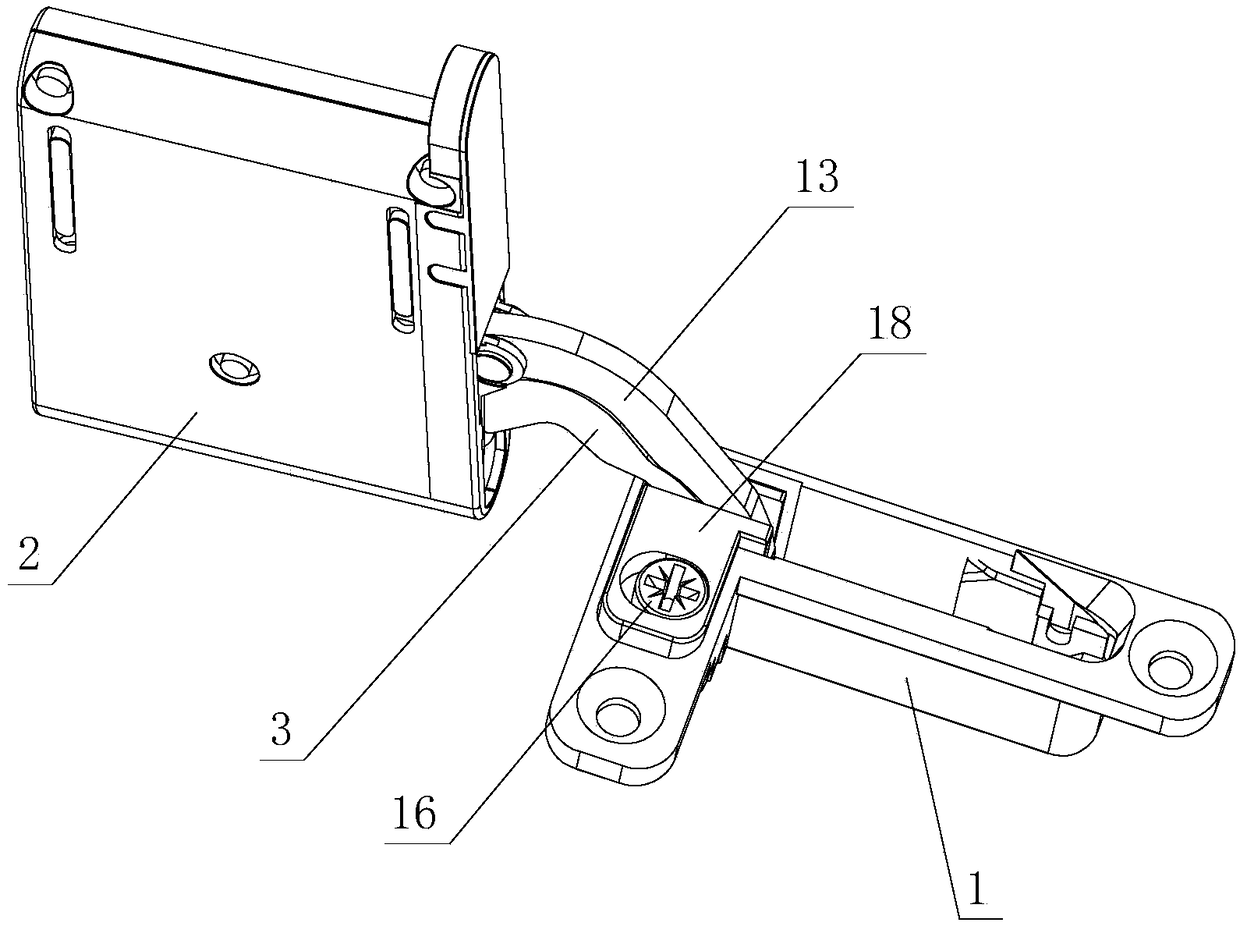

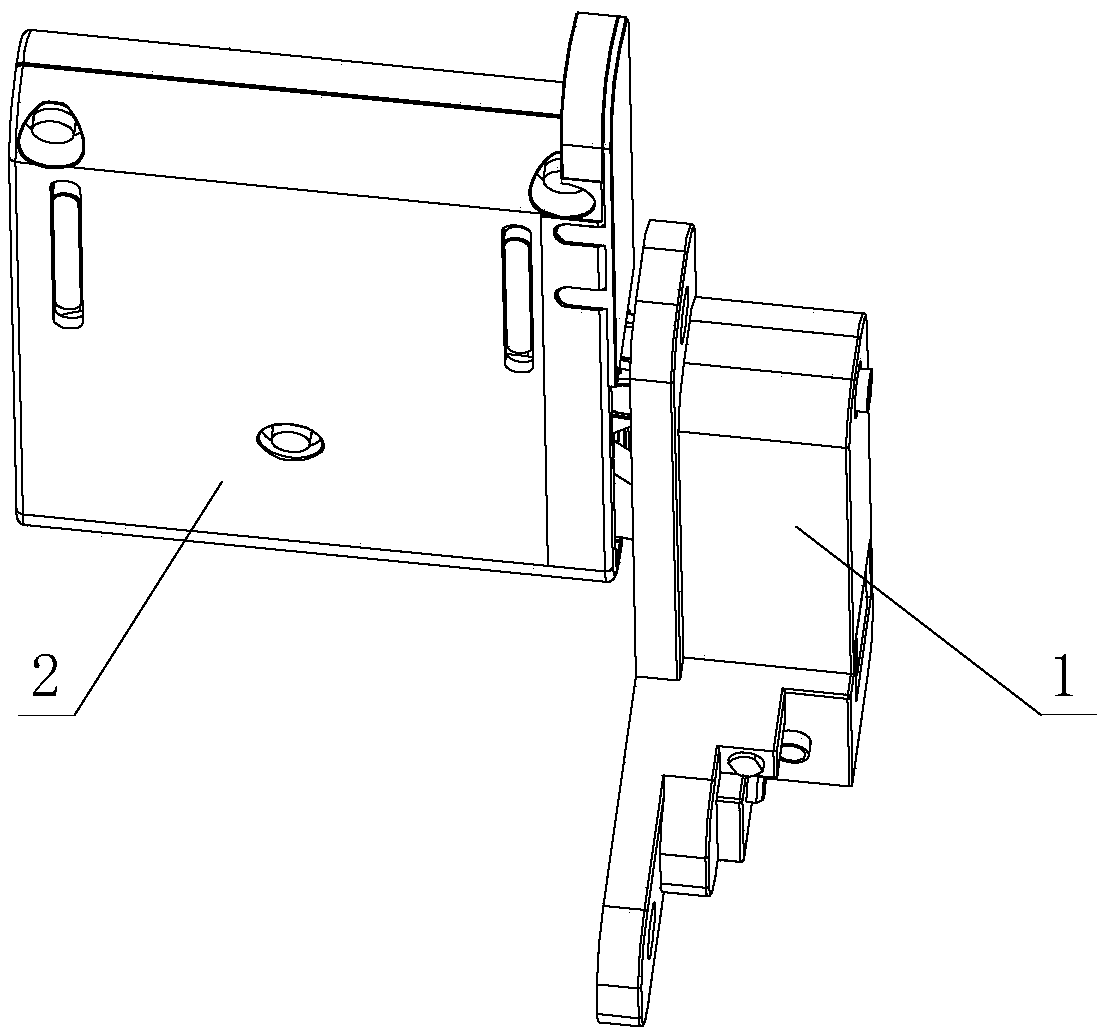

[0025] see Figure 1-Figure 6 , the embedded hinge structure includes a hinge cup 1 and a fixed bracket 2 that are hinged and opened and closed through the connecting arm assembly. The fixed bracket 2 is also provided with an elastic device and a damper. The connecting arm assembly includes at least the first connecting arm 3 , one end of the first connecting arm 3 is rotatably connected to the hinge cup 1, and the other end is rotatably connected to the fixed bracket 2. The first connecting arm 3 is also provided with an elastic action part 4 and a damping action part 5; the first connecting arm 3 When the hinge cup 1 is hingedly opened and / or closed at a certain position relative to the fixed bracket 2, the elastic action part 4 interacts with the elastic device to realize the elastic hinge opening and / or closing of the hinge cup 1 relative to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com