Well-sinking method on muddy ground and first section shaft structure of open caisson

A wellbore and first section technology, applied in the field of first section wellbore structure, can solve the problems of difficult control of the wellbore subsidence speed and easy occurrence of sudden subsidence, and achieve the effects of reducing the bottom sealing process, accelerating subsidence, and speeding up the construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

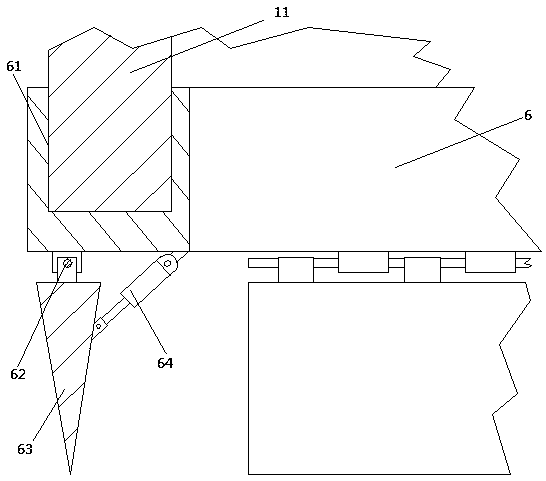

[0016] Embodiment one, see figure 1 , a first shaft structure of a caisson, including a shaft 1. The shaft includes a shaft wall 11 of reinforced concrete structure and several vertical partition walls 12 located in the space enclosed by the shaft wall. There are two vertical and two very vertical partition walls, a total of 4 pieces. The vertical partition wall isolates nine well holes 13 extending in the vertical direction in the space enclosed by the well bore wall. The lower end of the well hole in the middle is closed to form a closed structure. The lower ends of the remaining 8 well holes are connected with hydraulic gates 2 for closing the well holes. The hydraulic gates in 4 well holes are closed, and the other 4 hydraulic gates are open. A lifting propeller 4 that drives the wellbore to rise and a descending propeller 5 that drives the wellbore to descend are connected through the connecting frame 3 in the wellbore with the lower end closed. The connecting frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com