Jacquard chain warping machine

A technology of warping machines and jacquard chains, which is applied in the direction of warping machines, manufacturing tools, and other manufacturing equipment/tools, etc., to achieve the effect of small structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

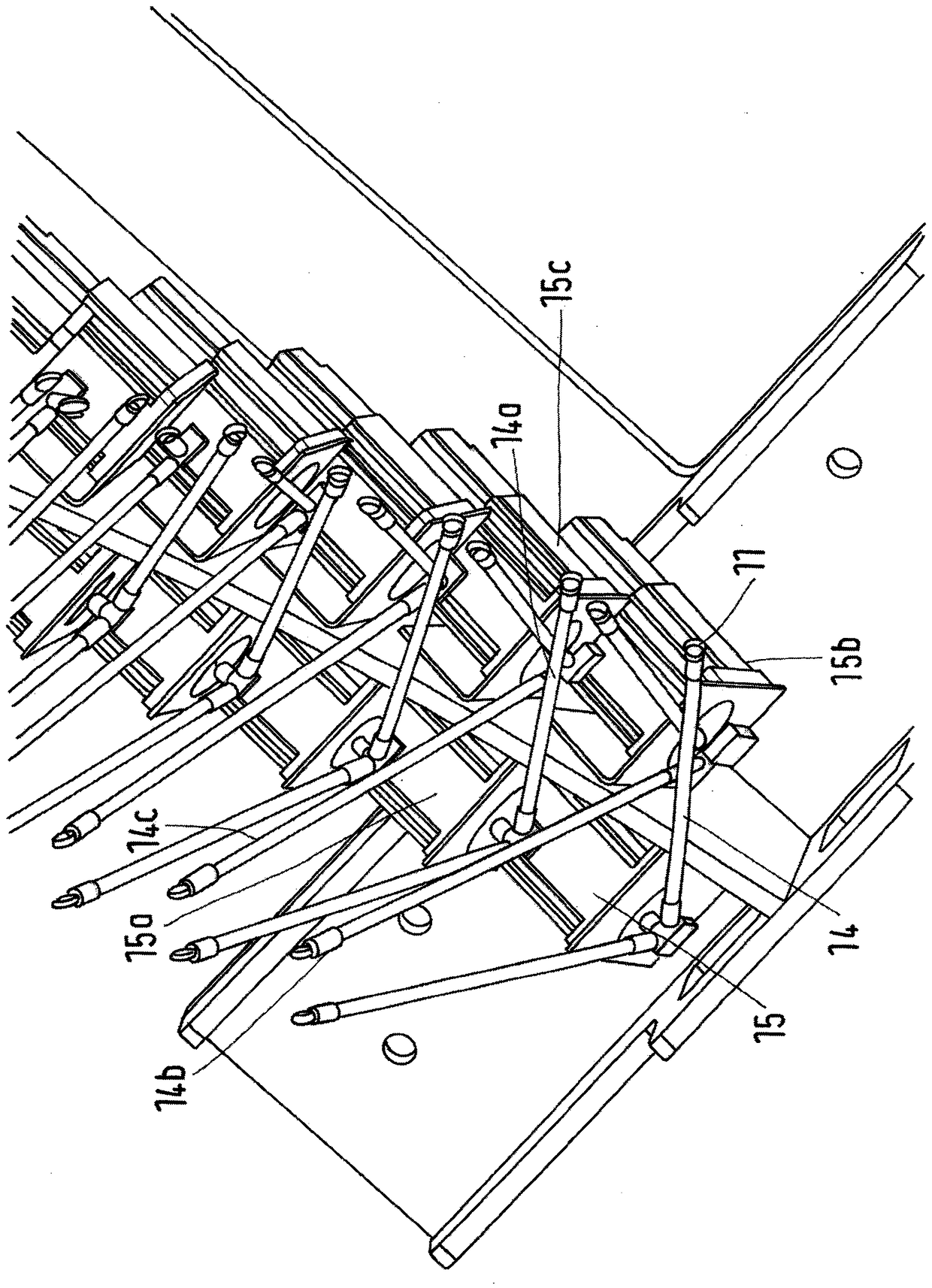

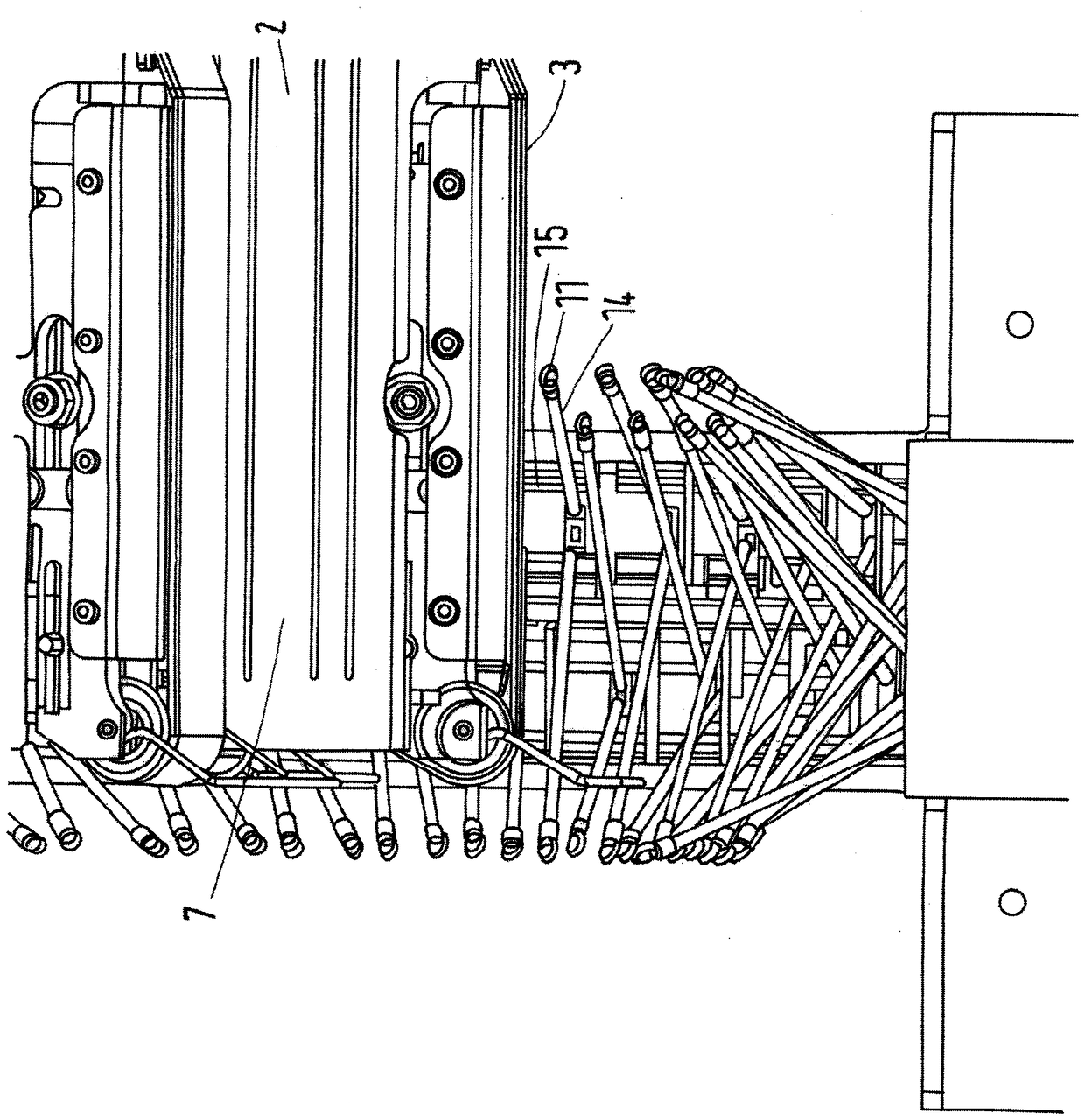

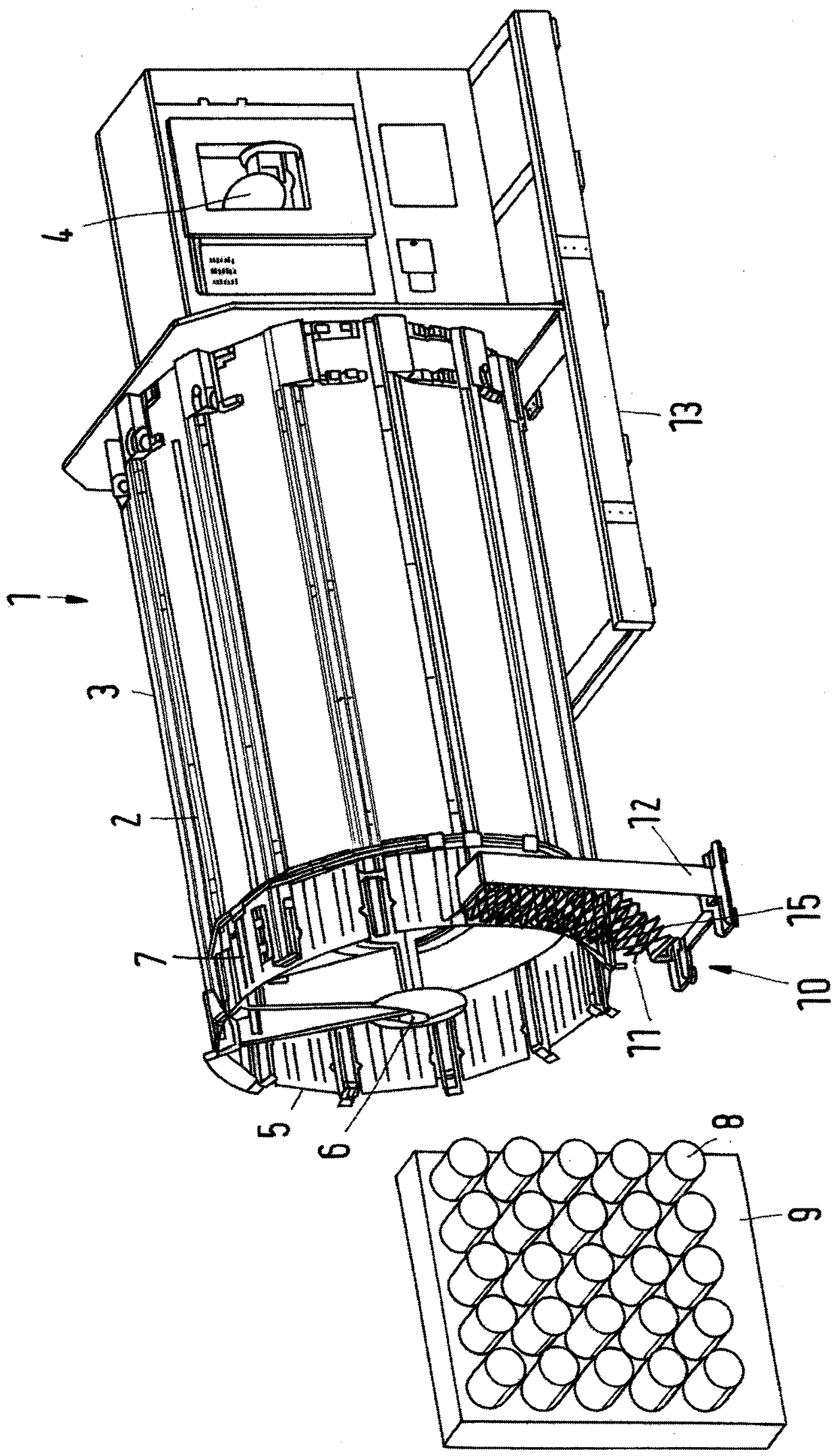

[0025] The Jacquard chain warper 1 has a warping cylinder 2 on whose circumference a plurality of transport surfaces 3 are arranged. The conveying surface 3 is formed here by a conveyor belt which can move parallel to the axis of the warping cylinder 2 .

[0026] The warping cylinder 2 is driven by an operating winding drive 4 . Here it can reach peripheral speeds of up to 800 m / min.

[0027] The warping cylinder 2 has a free end side 5 . The free end side is arranged at the end of the warping cylinder 2 facing away from the winding drive 4 . An inlet 6 for an auxiliary conveying device, not shown in more detail, the function of which will be explained below is provided at the free end face 5 .

[0028] The warping cylinder 2 has a storage area 7 in the region of the free end. In the area of the storage area 7, the yarn is stored on the circumference of the warping cylinder 2 during chain production. Here, the yarn is fed in the form of so-called "little ribbons", that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com