Preparation method of cell structure gradient tungsten alloy material

A technology of structural gradient and tungsten alloy, which is applied in the field of preparation of cell structure gradient tungsten alloy materials, can solve the problems of limited effect, change of toughness phase composition, etc., and achieve the goal of inhibiting grain growth, improving alloy performance and preventing sintering deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

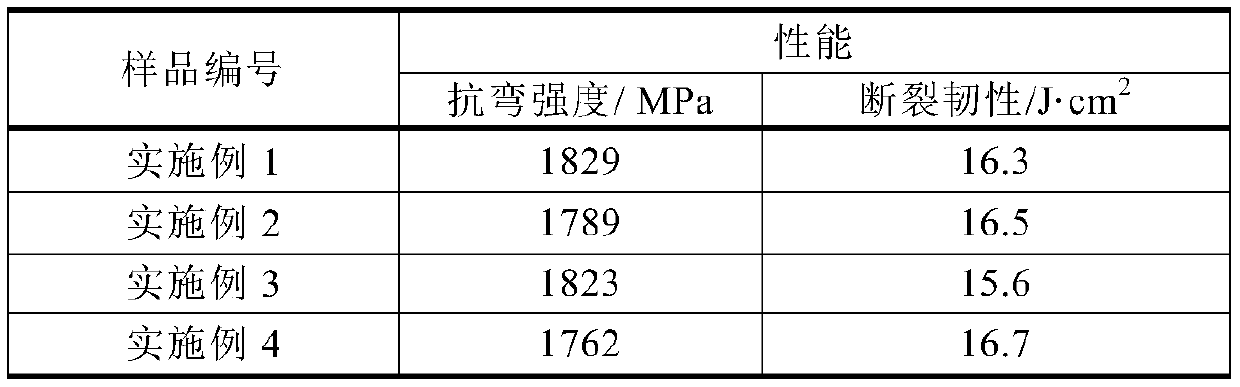

Examples

preparation example Construction

[0021] A kind of preparation method of cell structure gradient tungsten alloy material of the present invention comprises the following steps:

[0022] (1) According to the mass percentage of each component ratio in high tungsten, it is 98.3~99.0%W, 0.6~1.3%Ni and 0.4~0.9%Mn; the mass percentage of each component ratio in low tungsten is 88.4~90.1%W, 6.0-7.7% Ni, 3.9-5.6% Mn, weigh tungsten powder, nickel powder and manganese powder, place them in a high-energy ball mill respectively, and perform pre-alloying treatment to obtain two pre-alloyed powders. The speed of the ball mill is 520-710 rpm , Ratio of ball to material (3.6~5.2): 1, ball milling time 25~40 hours, ball milling tank and balls are made of cemented carbide.

[0023] (2) The high tungsten pre-alloy powder is subjected to atomization drying and granulation. The atomizer rotation speed of the atomization drying granulator is 21000-23000 rpm, and the air inlet / outlet temperatures are 190°C and 60°C respectively. T...

Embodiment 1

[0028] (1) Weigh tungsten powder, Nickel powder and manganese powder are respectively placed in a high-energy ball mill for pre-alloying treatment to obtain two pre-alloyed powders. The ball mill speed is 590 rpm, the ball-to-material ratio is 4.1:1, and the ball milling time is 25 hours. The ball mill pot and ball material All are cemented carbide.

[0029] (2) The high tungsten pre-alloy powder is subjected to atomization drying and granulation, the atomizer rotation speed of the atomization drying granulator is 21000 rpm, the air inlet / outlet temperature is 190°C and 60°C respectively, and the particle size of the dry powder is 70 μm; The prepared high tungsten-based spherical powder and low tungsten-based pre-alloyed powder are placed in an inert atmosphere slow-speed mixer and stirred evenly at a mass ratio of 7.2:1. The slow-speed mixer rotor speed is 20 rpm, and the stirring time is 50 minutes.

[0030] (3) Add 2% SBS forming agent into the mixed powder, put it into a ...

Embodiment 2

[0033] (1) Weigh tungsten powder, Nickel powder and manganese powder are respectively placed in a high-energy ball mill for pre-alloying treatment to obtain two pre-alloyed powders. The ball mill speed is 610 rpm, the ball-to-material ratio is 3.6:1, and the ball milling time is 35 hours. The ball mill pot and ball material All are cemented carbide.

[0034] (2) The high tungsten pre-alloy powder is subjected to atomization drying and granulation. The atomizer speed of the atomization drying granulator is 23000 rpm, the temperature of the air inlet / outlet is 190°C and 60°C respectively, and the particle size of the dry powder is 72 μm; The prepared high tungsten-based spherical powder and low tungsten-based pre-alloyed powder are placed in an inert atmosphere slow-speed mixer and stirred evenly at a mass ratio of 7.4:1. The slow-speed mixer rotor speed is 20 rpm, and the stirring time is 50 minutes.

[0035] (3) Add 2% SBS forming agent into the mixed powder, put it into a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com