A kind of building assembly hoisting equipment

A kind of hoisting equipment and rigid technology, applied in the direction of hoisting device, lifting frame, etc., can solve the problems of inability to protect safely, adjust the lifting range of lifting gear, and poor safety protection ability of the device, so as to improve the intelligent controllability and avoid intelligent controllability Poor, the effect of improving security protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

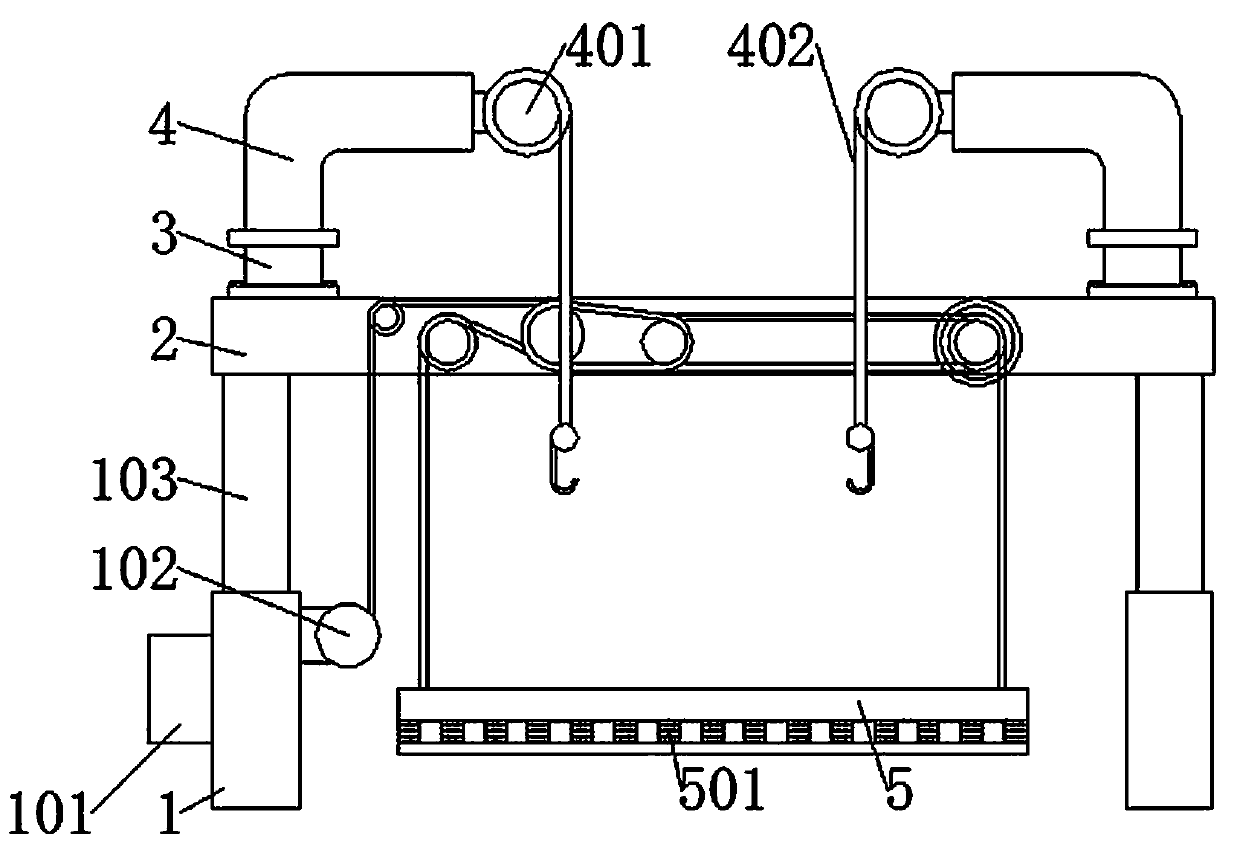

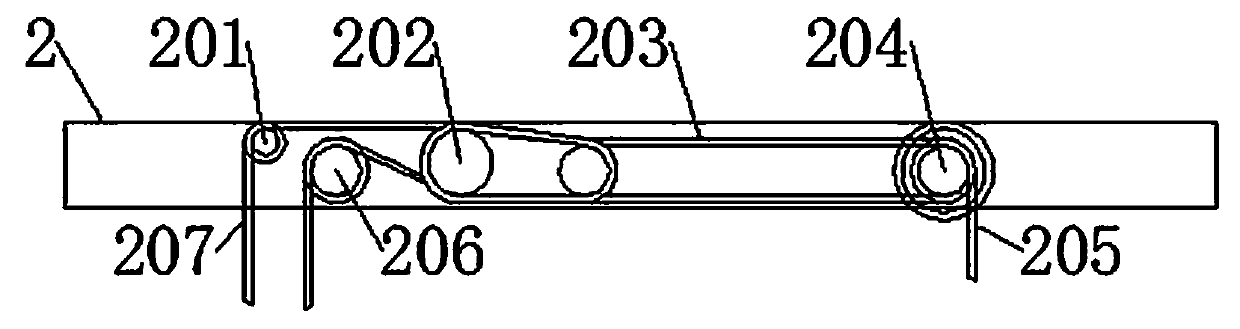

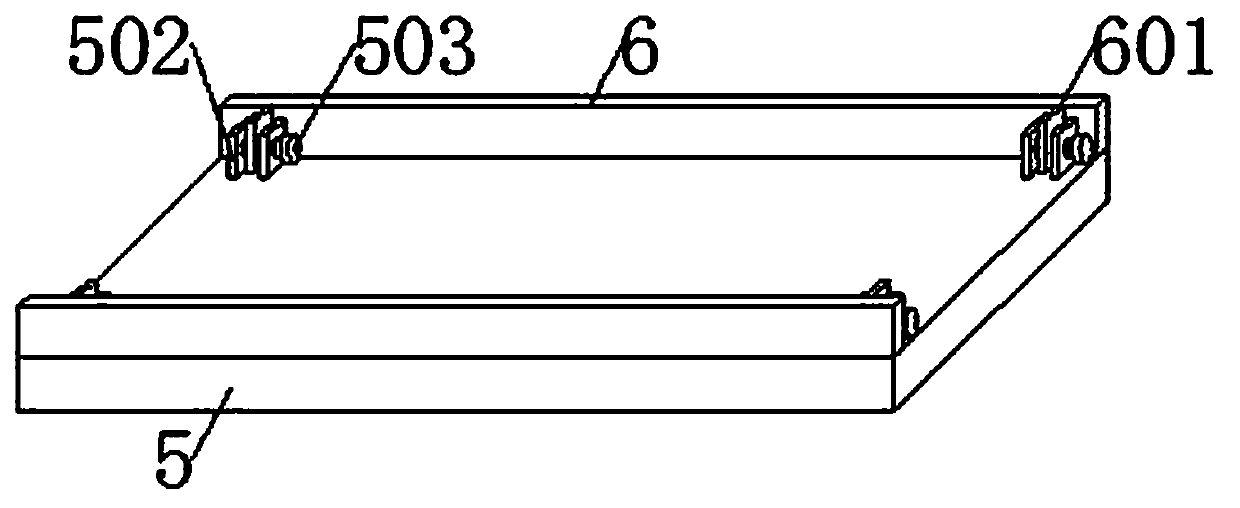

[0027] see Figure 1-4 , the present invention provides a technical solution: a building assembly hoisting equipment, including a rigid straight cylinder 1, a work frame 2 and a loading plate 5, two symmetrical hydraulic lifting columns 103 are arranged at the bottom end of the work frame 2, two hydraulic lifting columns 103 The lifting column 103 is extended to the other end to be sleeved with two rigid straight cylinders 1. One side of one rigid straight cylinder 1 is provided with a control box 101. Two symmetrical rotators 3 are arranged on the top of the rotator, two steel columns 4 are welded to the other end of the two rotators 3, and two steel chain restrainers 401 are fixedly connected to the other end of the two steel columns 4. There are two steel chains 402 connected to the internal transmission of the two steel chain constrictors 401, two symmetrical baffles 6 are arranged on the top of the loading plate 5, and four For the first steel plate 502, and the four fir...

Embodiment 2

[0029] In an embodiment, a building assembly hoisting device includes a rigid straight cylinder 1, a work frame 2 and a loading plate 5, two symmetrical hydraulic lifting columns 103 are arranged at the bottom end of the working frame 2, and the two hydraulic lifting columns 103 extend Two rigid straight cylinders 1 are sleeved to the other end, one side of one rigid straight cylinder 1 is provided with a control box 101, the other side of the rigid straight cylinder 1 close to the control box 101 is welded with a gear chain transmission 102, and the top of the working frame 2 is provided with a Two symmetrical rotators 3, the two rotators 3 extend to the other end and are welded with two steel columns 4, the two steel columns 4 extend to the other end and are fixedly connected with two steel chain restrainers 401, the two steel chains There are two steel chains 402 connected to the internal transmission of the bundler 401, two symmetrical baffles 6 are arranged on the top of t...

Embodiment 3

[0032] In an embodiment, a building assembly hoisting device includes a rigid straight cylinder 1, a work frame 2 and a loading plate 5, two symmetrical hydraulic lifting columns 103 are arranged at the bottom end of the working frame 2, and the two hydraulic lifting columns 103 extend Two rigid straight cylinders 1 are sleeved to the other end, one side of one rigid straight cylinder 1 is provided with a control box 101, the other side of the rigid straight cylinder 1 close to the control box 101 is welded with a gear chain transmission 102, and the top of the working frame 2 is provided with a Two symmetrical rotators 3, the two rotators 3 extend to the other end and are welded with two steel columns 4, the two steel columns 4 extend to the other end and are fixedly connected with two steel chain restrainers 401, the two steel chains There are two steel chains 402 connected to the internal transmission of the bundler 401, two symmetrical baffles 6 are arranged on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com