Fast pin puller

A pin puller and fast technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of slipping, laborious cooperation between the pin puller and the positioning pin thread, etc., and achieve the effects of easy use, avoiding slipping, and improving pin pulling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

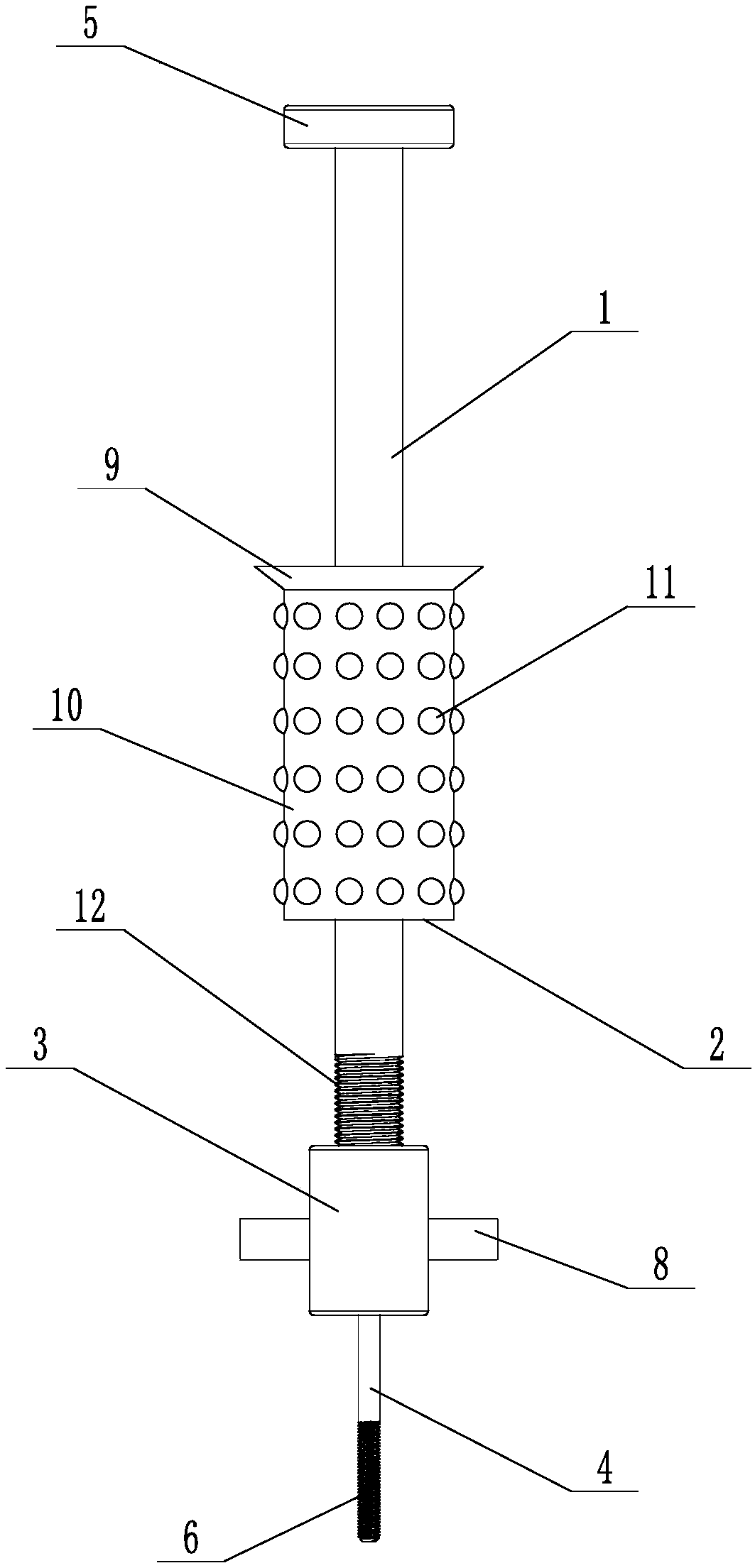

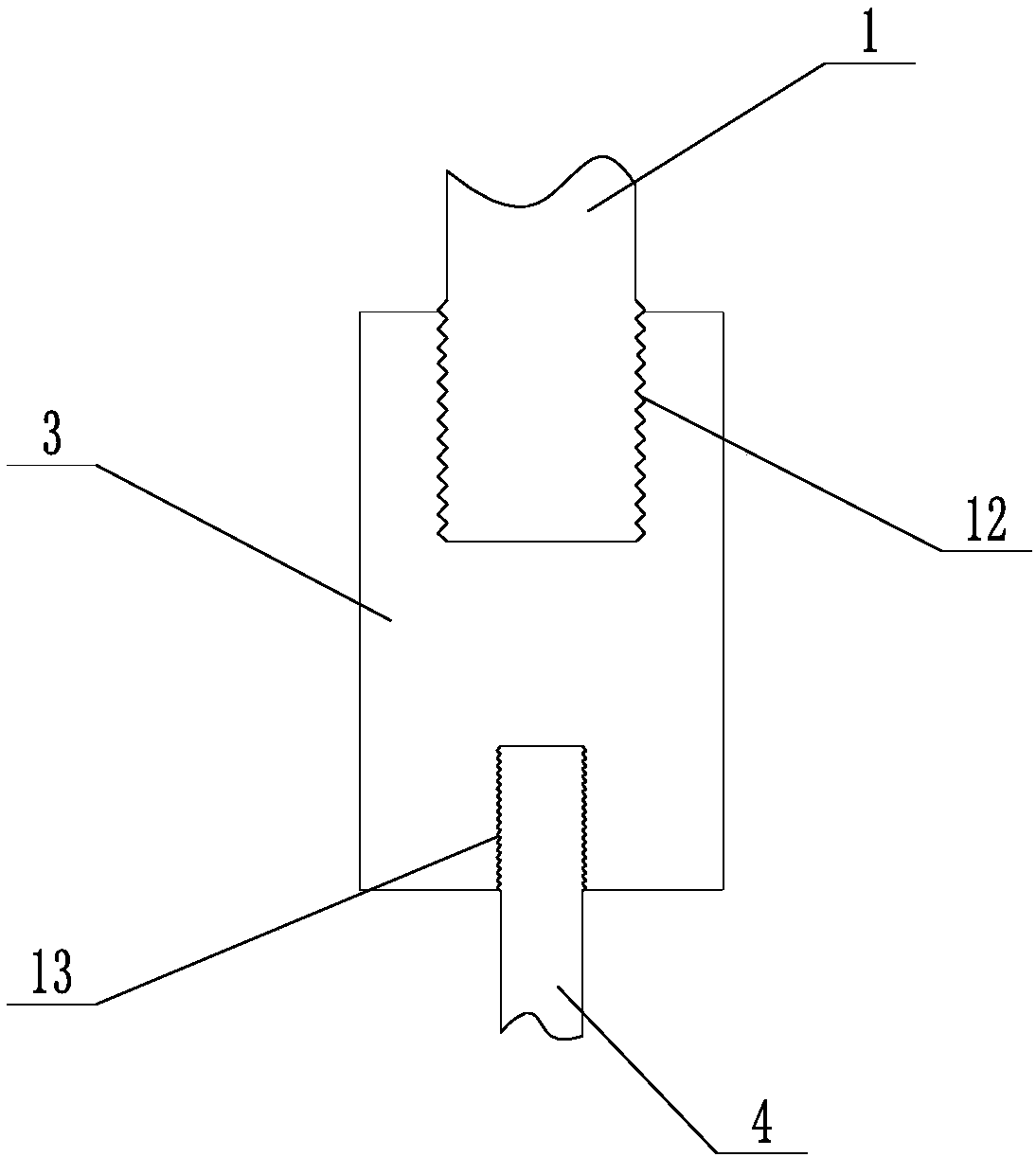

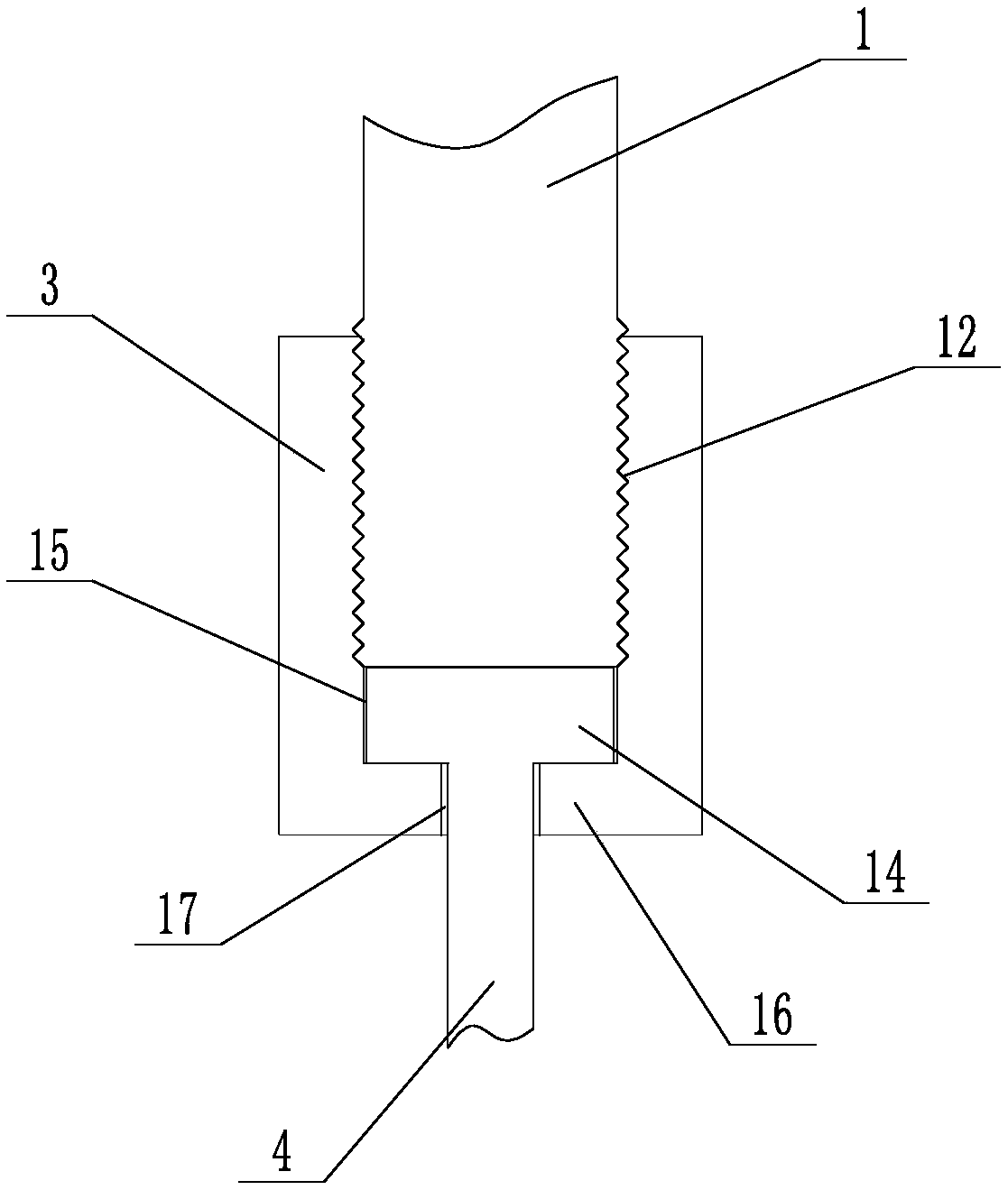

[0018] like Figure 1 to Figure 3 As shown, a quick pin puller includes a puller 1, a drive block 2, a connecting block 3 and a bolt 4. The puller 1 is arranged in a cylindrical shape, and the drive block 2 is installed in the middle of the puller 1 and can be opposite to the puller 1. Moving along its axial direction, the top of the pull rod 1 is provided with a positioning block 5 that abuts against the drive block 2 and limits the upward movement of the drive block 2, and the connecting block 3 is fixedly installed on the bottom end of the pull rod 1 through screw connection , the connecting block 3 abuts against the driving block 2 and limits the downward movement of the driving block 2. One end of the bolt 4 is provided with a first threaded connection part 6 that matches the threaded hole on the pin, and the other end is provided with a threaded connection part 6 for connecting with the The block 3 is fixedly connected to the mounting portion 7 , and the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com