Stable adsorption fixture

A jig and stable technology, used in manufacturing tools, workpiece clamping devices, etc., can solve problems such as inability to effectively fix the jig, large assembly errors, etc., to achieve easy assembly accuracy, avoid relative position movement, and high assembly accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

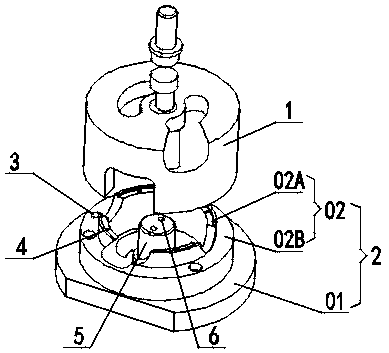

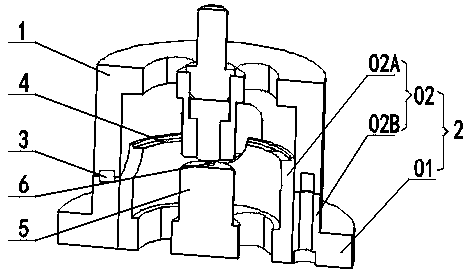

[0034] A stable adsorption fixture, such as figure 1 and figure 2As shown, it includes an upper jig 1 and a lower jig 2 that is movably engaged with the upper jig 1, and is characterized in that the lower jig 2 includes a bottom plate 01 and an annular outer wall 02 arranged on the bottom plate 01, The annular outer wall 02 includes an annular upper step 02A and an annular lower step 02B coaxially arranged in sequence from top to bottom, and the diameter of the upper step 02A is smaller than the diameter of the lower step 02B; the top of the upper step 02A There are several pendulum suction holes 4 penetrating through the bottom plate 01 on the surface; the top surface of the bottom plate 01 and the interior of the annular outer wall 02 are equipped with a lower stand 5, which is connected to the upper step 02A respectively. It is arranged coaxially with the lower step 02B; the top surface of the lower stand 5 is provided with several lower frame suction holes 6 penetrating ...

Embodiment 2

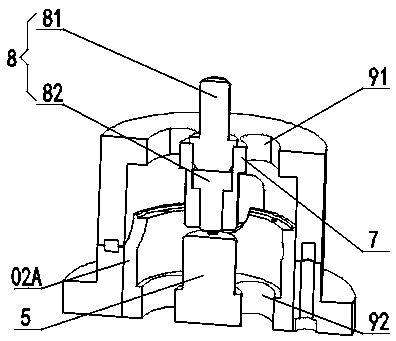

[0038] This embodiment is further optimized on the basis of the above-mentioned embodiment 1, such as image 3 and Figure 4 As shown, the upper jig 1 is provided with a hollow tubular movable snap-in cover that is movably engaged with the lower jig 2 , and the inner top of the movable snap-in cover corresponds to the lower stand 5 and is coaxially provided with a cylindrical upper The stand 7, the inside of the upper stand 7 is provided with an installation cavity 71 which penetrates up and down and is arranged coaxially with the lower stand 5, and the pressing device 8 is installed in the installation cavity 71. On the top surface of the lower step 02B and on the fastening surface of the upper jig 1 are provided with several corresponding adsorption holes along the circumferential direction, and magnets 3 are arranged in the adsorption holes; the upper jig 1 The upper correction hole 91 and the lower correction hole 92 are arranged correspondingly on the lower fixture 2, an...

Embodiment 3

[0046] This embodiment is further optimized on the basis of the above-mentioned embodiment 1, such as Figure 5 As shown, the bottom surface of the movable clamping cover of the upper fixture 1 and the step surface of the lower step 02B are also provided with corresponding positioning pin holes 03, and the positioning pin holes 03 are provided with positioning pins. The upper jig 1 is anti-rotationally locked with the lower jig 2 through positioning pins; one side of the bottom plate 01 is milled with a pressing plane 04; the outer wall of the upper jig 1 is also provided with a through groove penetrating the outer wall.

[0047] The positioning pin hole 03 corresponding to the position is also set on the step surface of the lower step 02B. After the upper jig 1 and the lower jig 2 are fastened, the positioning pin is inserted into the positioning pin hole 03 to avoid the upper jig 1 and the lower jig. There is relative rotation between the tools 2. On one side of the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com