Corn kernel threshing and separating device

A technology for threshing and separating grains, which is applied in threshing equipment, applications, agricultural machinery and tools, etc. It can solve the problems of low cleaning rate, high grain breaking rate, and poor separation effect, so as to improve the cleaning rate and enhance the threshing effect , the effect of reducing the broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

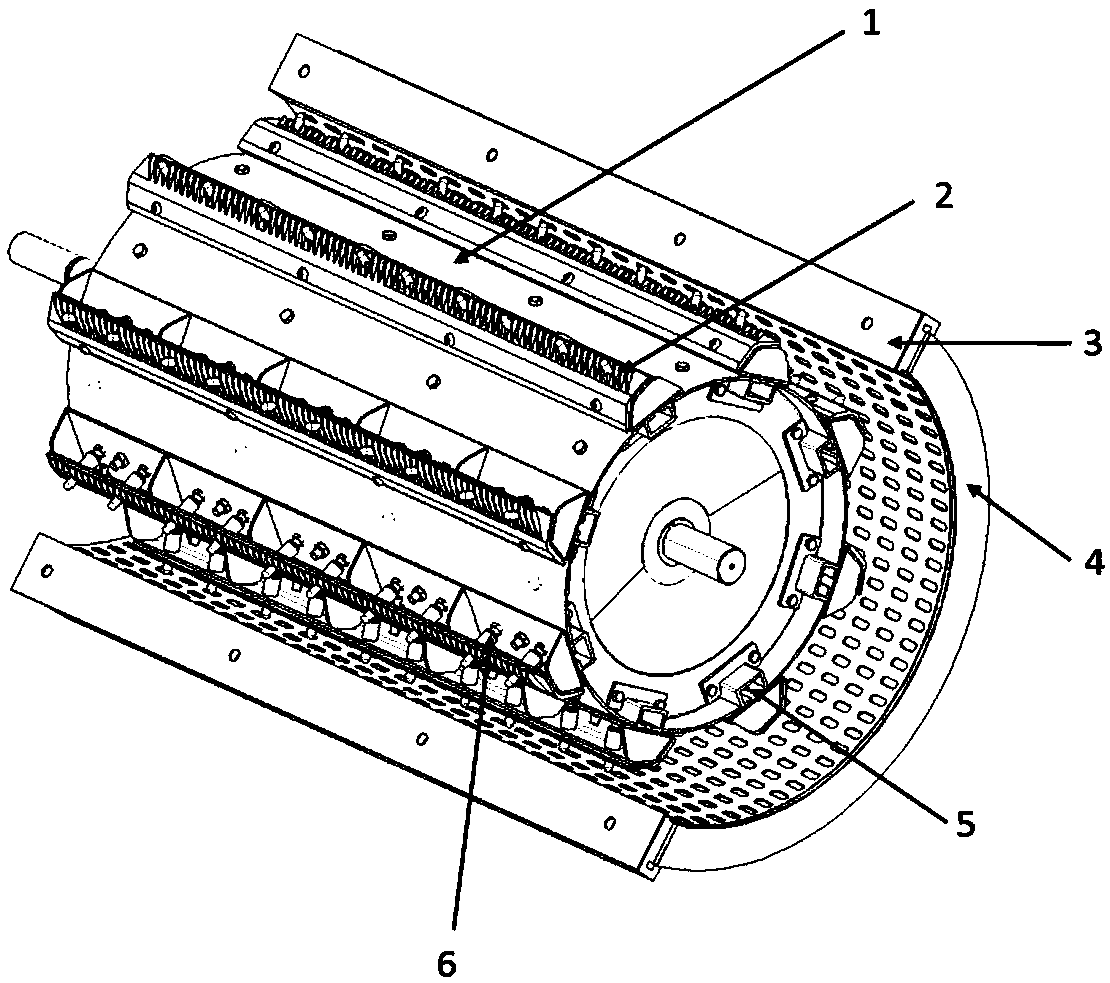

[0039] figure 1 It is an embodiment of a corn grain threshing and separation device according to the present invention, and the corn grain threshing separation device includes a threshing drum 1, several combined threshing elements 2 and a threshing concave plate;

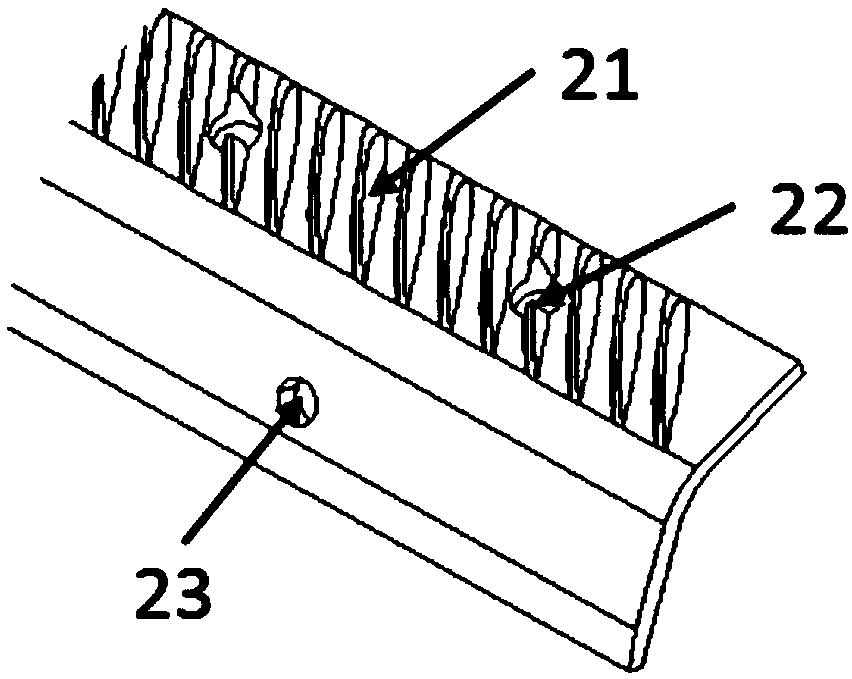

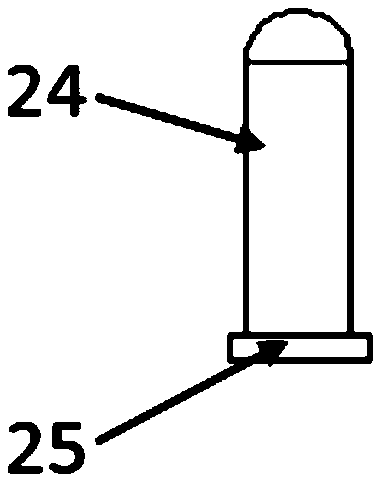

[0040] The combined threshing element 2 is distributed on the cylinder surface of the threshing cylinder 1 along the axial direction, and the combined threshing element 2 includes a bar tooth 21, a number of ball nail teeth 24 and a telescopic support base 6. The bar tooth 21 Installed on the telescopic support base 6, the telescopic support base 6 is installed on the threshing drum 1 by bolts; the top of the corrugated rod tooth 21 is provided with a number of through holes 22, and the bottom of the ball-head nail tooth 24 is connected to the telescopic The support base 6 is connected, and the top of the ball stud 24 corresponds to and matches the position of the through hole 1 22;

[0041] Below the threshing cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com