Fiber structure and method for changing laser beam profile

A technology of laser beams and optical fibers, applied in the field of laser systems, which can solve the problems of expensive, time-consuming, and damage to fragile optical components of laser systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

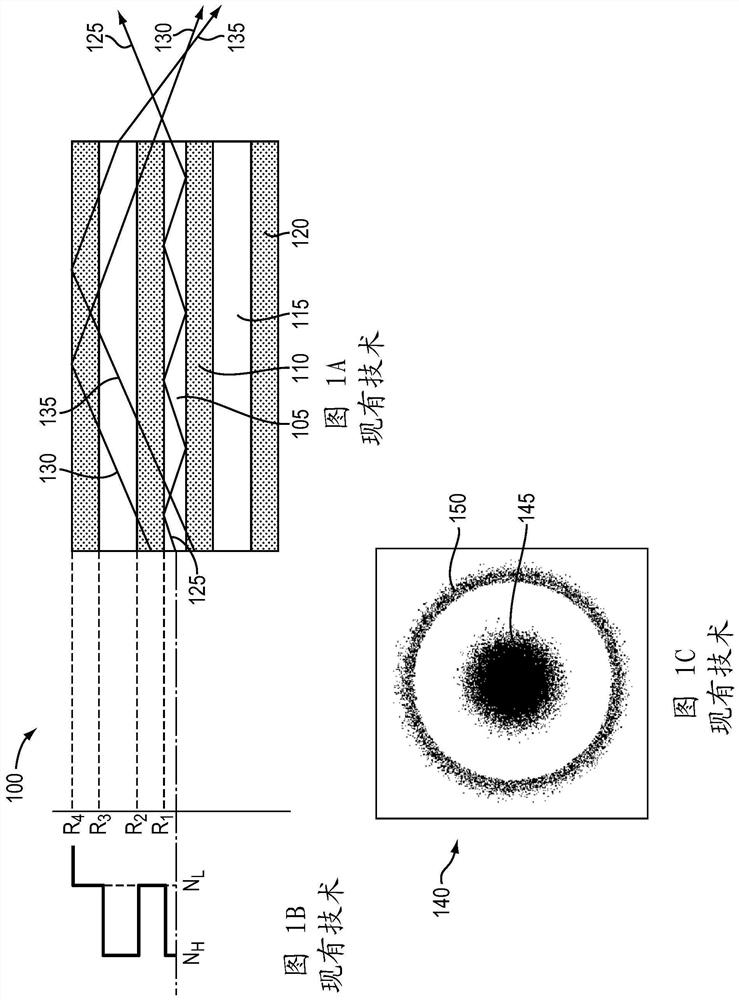

[0034] Figure 1A Shows a conventional double-clad fiber 100, having a central core 105, inner cladding 110, the core 115 and the outer annular layer 120. The radius of each layer (the core or cladding) of the optical fiber 100 by R 1 R 2 R 3 Or R 4 Said that if Figure 1B Indicated. In the conventional double-clad fiber 100, two cores 105, 115 have generally the same high refractive index N H , 110, 120 and the two cladding generally has the same lower refractive index N L ,like Figure 1BShown, therefore, two cores 105, 115 having the same NA: sqrt (N H 2 NN L 2 .

[0035] Figure 1A Also depicts transmission of light of the optical fiber 100 Three. Light 125 is coupled to the central core 105, restricted by the central core 105, and at the same angle it entered the central core 105 emitted from the central core 105. Ray 130 and ray 135 is transmitted to the inner cladding 110, spread over the entire area of the optical fiber, and an outer cladding 120 limit. Since the exit su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com