Pneumatic fry automatic marking machine

A pneumatic and fish fry technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of mark deformation, inconvenient identification, etc., and achieve the effect of avoiding bending, reducing biological damage, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

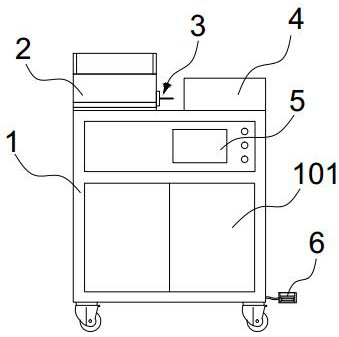

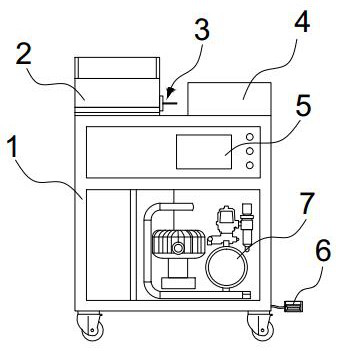

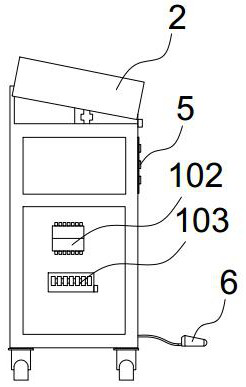

[0034] Such as Figure 1-7, shown in 10, the pneumatic fish fry automatic marking machine comprises the box body 1 that the top is respectively provided with the fry basin 2 to be marked and the fry basin 4 to be marked, the side of the box body 1 is equipped with a control panel 5, and the fry basin 2 to be marked Below is provided with the marking device 3 that is used for organism marking; The cutting mechanism and the injection mechanism for the biological injection line mark; the injection mechanism includes a standard inlet cylinder 304 for pushing the line mark, a transmission pipeline 306 for line mark transmission and a needle 307 for the biological injection line mark, and the transmission pipeline 306 and the needle head 307 are connected with a connecting sleeve 308, and the middle part of the pipe wall of the needle head 307 is provided with a spacer 307a. The present invention utilizes the control panel 5 to control each component in the box body 1 to realize the...

Embodiment 2

[0040] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: Figure 8 , 9 As shown, the surface of the line marking wire 303 can have a number for biological marking and a partition block 303a for separating the numbers. The numbers are engraved on the line marking wire 303 to facilitate operations such as marking and recording parameters for each marked organism. The separation block 303a is set between them to ensure the identification accuracy of the mark and avoid the garbled number of the mark. It is only necessary to read the number between the two separation blocks 303a to obtain the mark number, and the separation block 303a can also lift the thread marking wire 303 when cutting The precision in the process reduces the cutting error. The side of the cutting block 311 is provided with a grinding pattern 311b and a sloping chip storage groove 311a. During the marking process, the end of the wire marking wire 303 entering the cut...

Embodiment 3

[0042] When the pneumatic fry automatic marking machine of the present invention is actually used: the parameters of the marking organism are set through the control panel 5, for example, when marking the head of the large yellow croaker, the line marking wire of 0.2mm-0.25mm is selected, and the line The length of the mark is 0.25mm and other parameters, and the silicone sleeve corresponding to the shape of the head of the large yellow croaker is selected, and it is sleeved on the needle 307. The operator docks the head of the large yellow croaker with the needle 307 from the fry basin 2 to be marked. , and step down the pedal 6 to carry out the marking operation: the feeding motor 312 controls the feeding wheel 302 to realize the feeding mechanism to send the line marking wire 303 into the cutting chamber 313 according to the cutting length, and the cutting cylinder 305 controls the swing rod 310 to swing, and the swing rod 310 adopts the principle of leverage to drive the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com