Combined synchronous type permanent magnet coupler

A permanent magnetic coupling, synchronous technology, applied in the direction of permanent magnetic clutch/brake, electric brake/clutch, electric components, etc., can solve problems such as installation difficulties, and achieve the effect of avoiding mutual attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

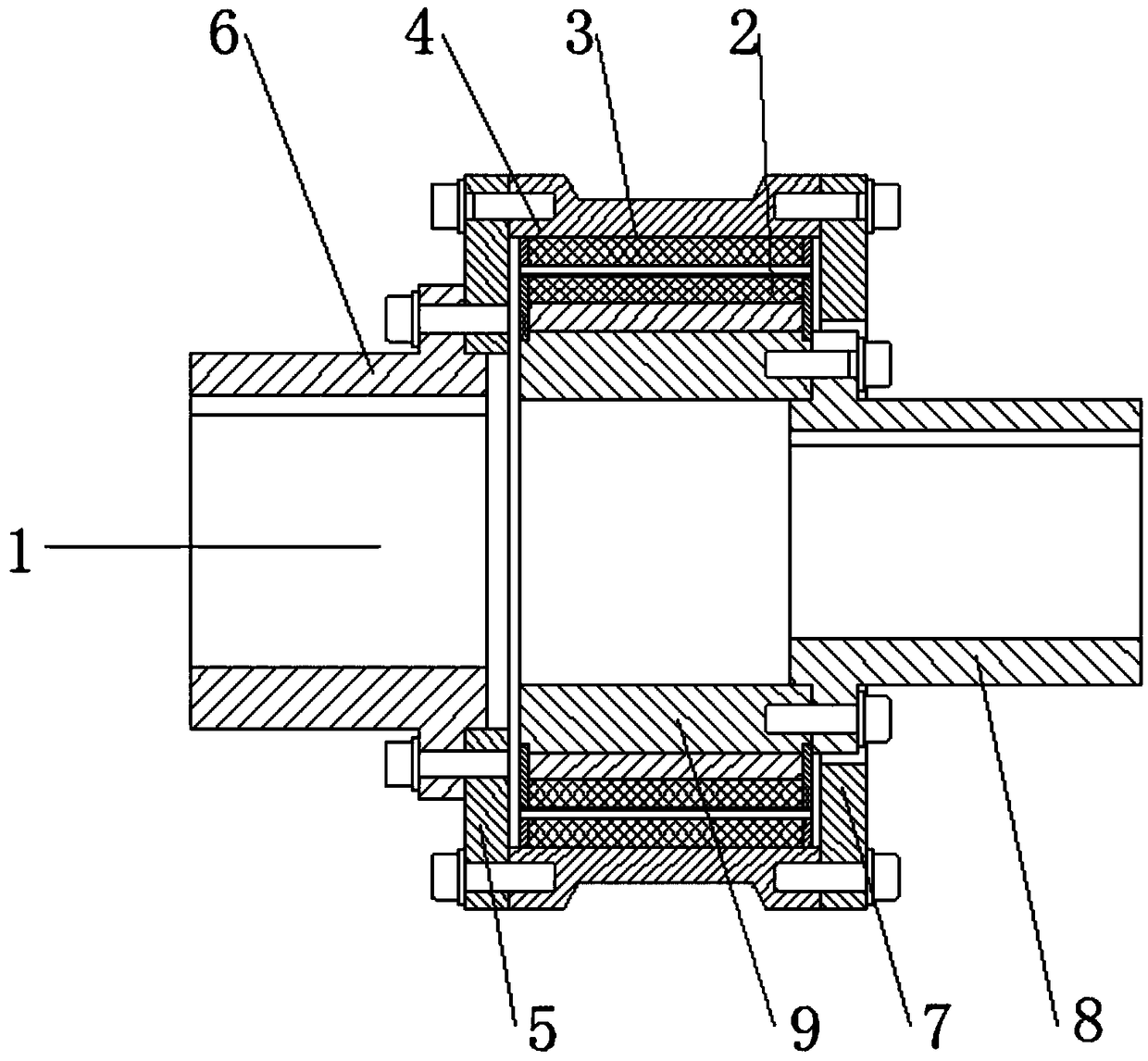

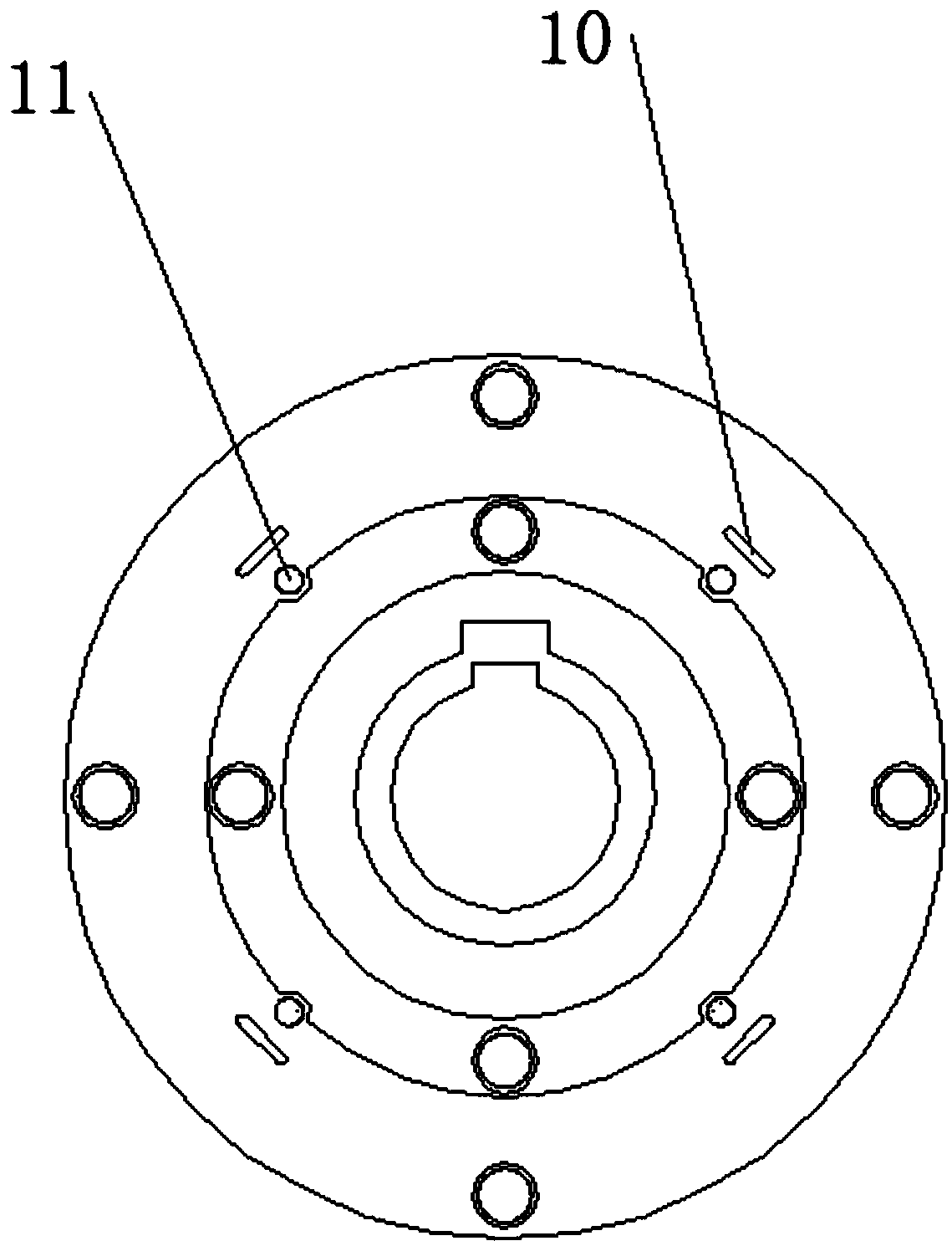

[0022] Embodiment 1: as Figure 1-2 As shown, the combined synchronous permanent magnet coupling includes a synchronous permanent magnet coupling body 1, and the synchronous permanent magnet coupling body 1 consists of a motor end bushing 6, a load end bushing 8 and a magnetic circuit The structure is composed of three parts, the three parts are connected together by connecting screws, and the magnetic circuit structure part is composed of connecting flange 1, connecting flange 2 7, driving rotor 4, driven rotor 9, driving rotor magnet 3, driven rotor magnet 2, and the active rotor 4, the active rotor magnet 3, the driven rotor magnet 2, and the driven rotor 9 are arranged sequentially from outside to inside, and an axial The positioning screw 11 and the radial positioning segment 10 are arranged outside the axial positioning screw 11 .

[0023] More specifically, the connecting flange one 5 is arranged on the left side of the connecting flange two 7, the motor end bushing 6 ...

Embodiment 2

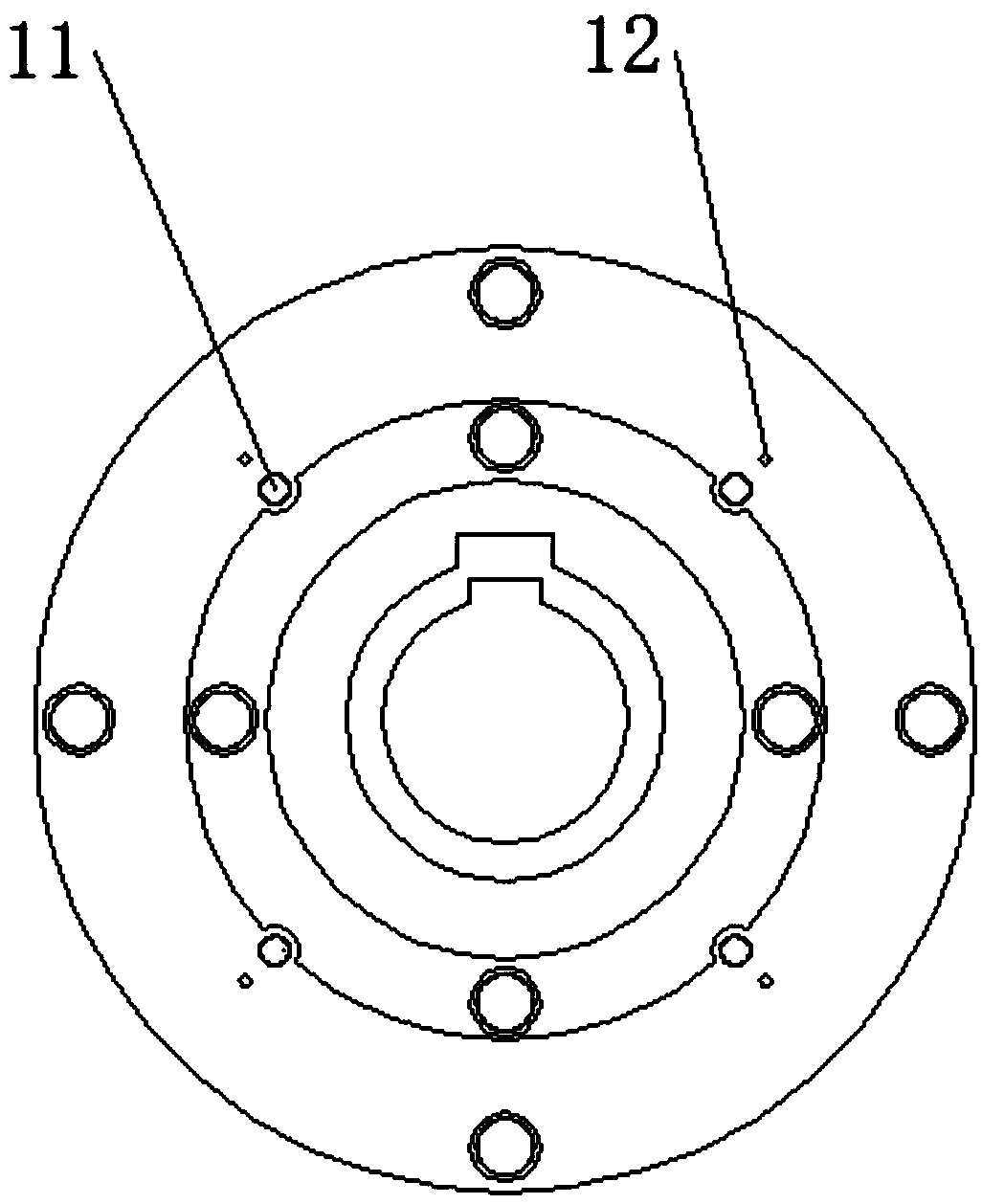

[0027] Embodiment 2: The radial positioning segment 10 in Embodiment 1 is replaced with a radial positioning pin 12 to achieve the same effect.

[0028] Completely solve the accidental suction of the rotor during transportation and installation, avoiding personal injury and equipment damage caused by suction; the combined structure makes the installation process easier, reduces the installation technical requirements for workers and masters, and reduces costs. Shorten the installation and maintenance cycle.

Embodiment 3

[0029] Embodiment 3: Remove the axial positioning jackscrew 11 in Embodiment 1, drill a hole in the outer circle of the active rotor, put a pin 13 in the hole, and the pin 13 is located between the magnetic block and the flange, and is used to control the two rotors The axial relative position between, basic principle is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com