Hydraulic jacking inverted-installing device for reducing tower and hoisting method thereof

A variable diameter tower and hydraulic technology, applied in towers, building types, buildings, etc., can solve the problems of prolonged installation and construction period, large number of cranes used, and high welding operation requirements, reducing scaffolding materials, short construction period, etc. High quality construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

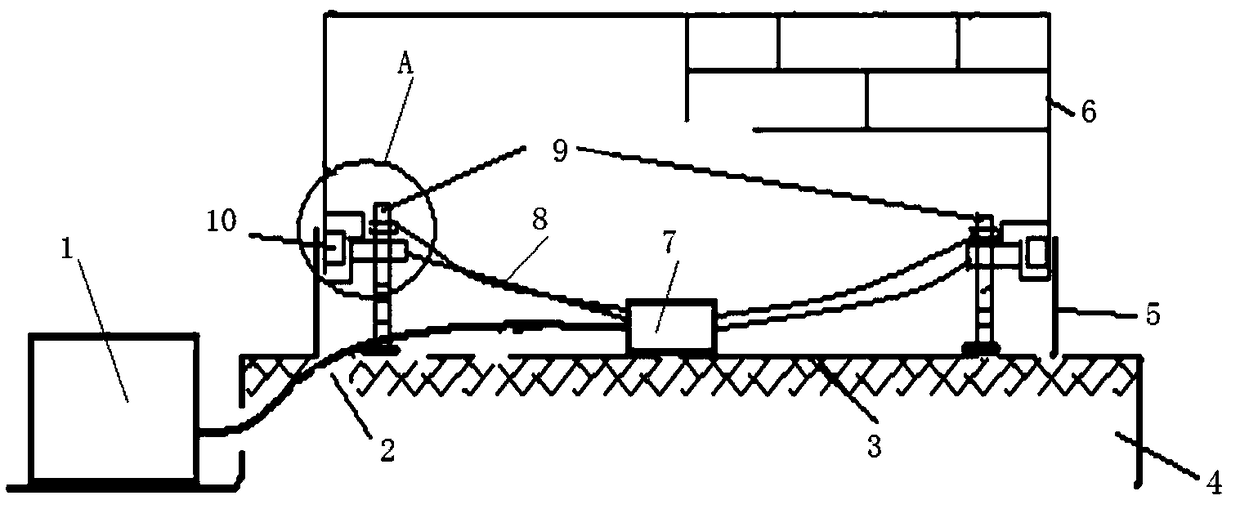

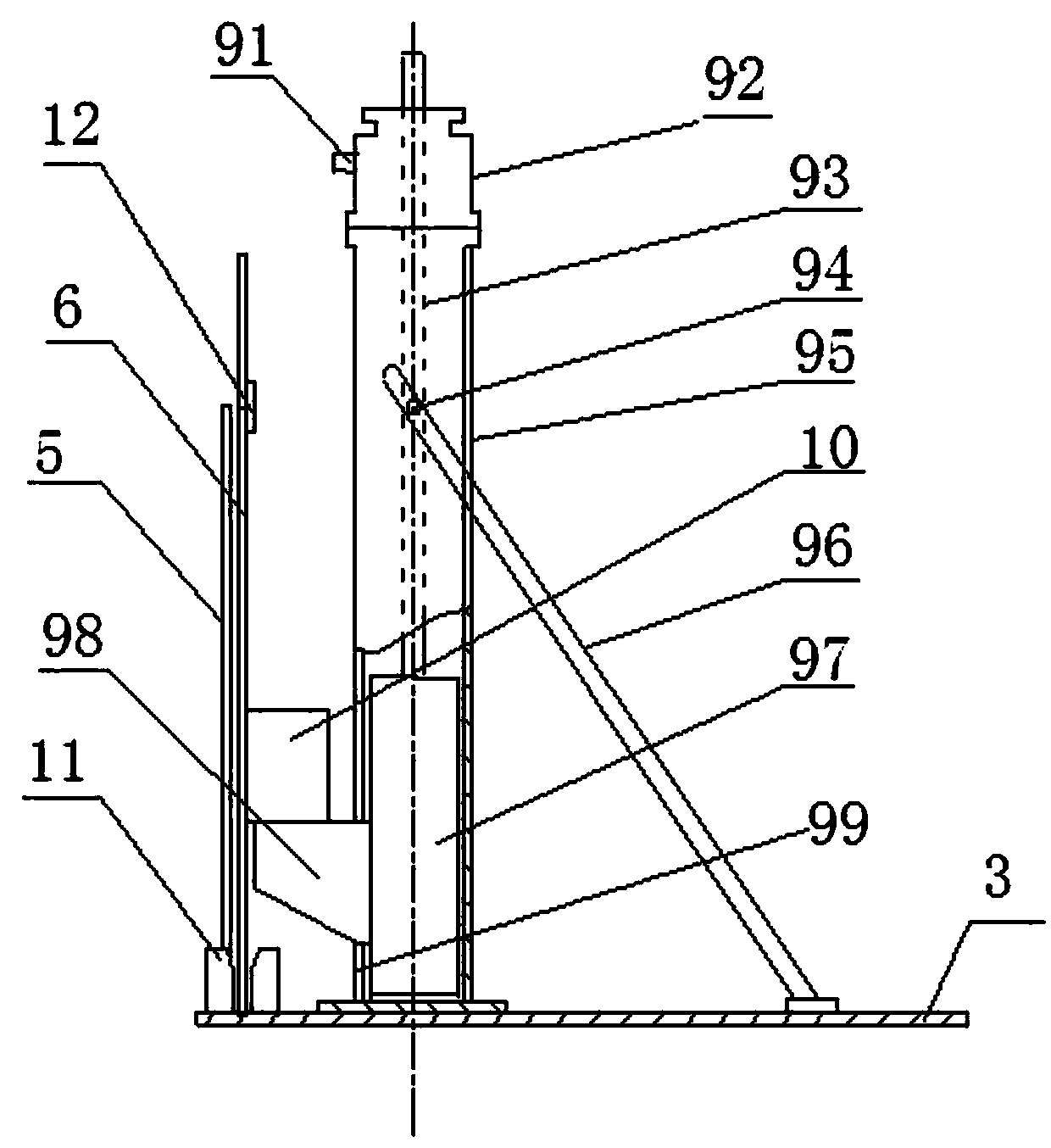

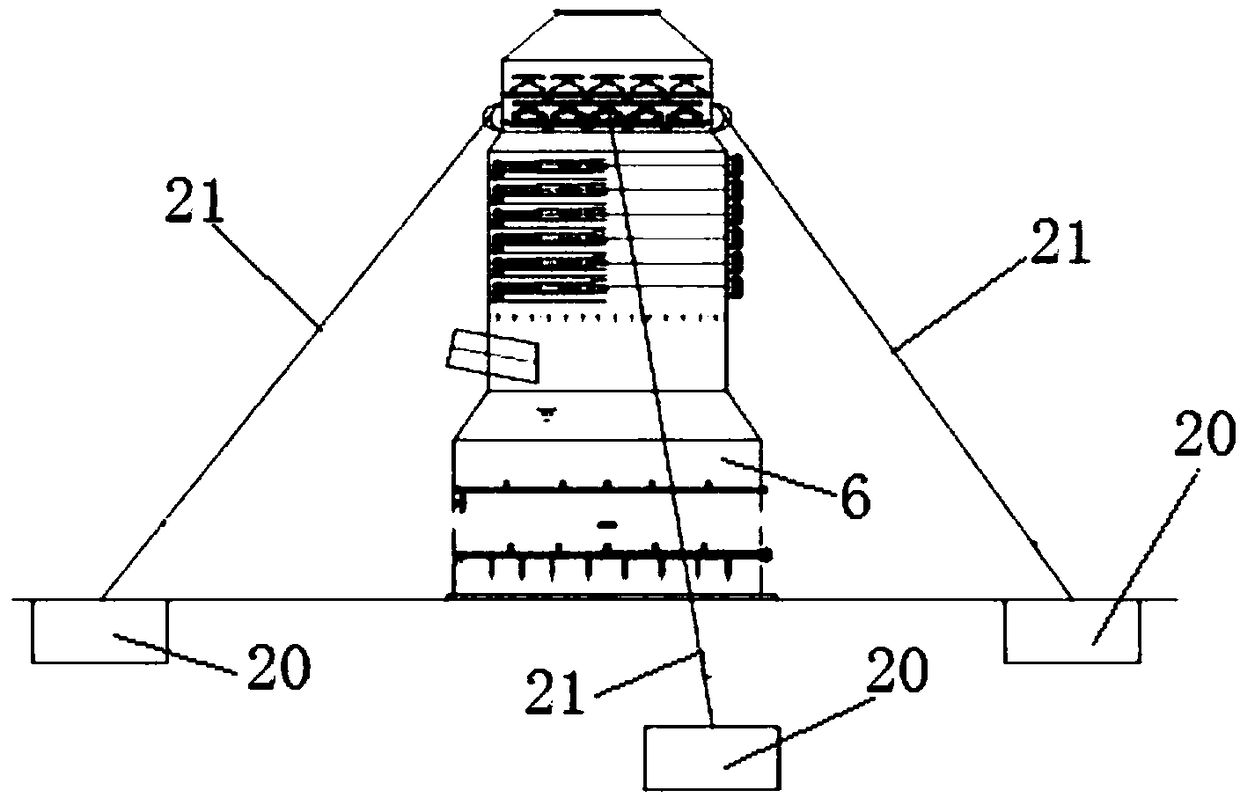

[0019] Embodiment 1: as attached Figure 1-6 As shown, a hydraulic jacking and inversion device for variable-diameter towers includes a tower foundation 4, a tower bottom plate 3 is arranged on the tower foundation 4, a hydraulic station 1 is arranged on the side of the tower foundation 4, and a tower bottom plate 3 is provided with an oil distributor 7, and a number of lifting devices 9 are provided around the oil distributor 7. The hydraulic station 1 is connected to the oil distributor 7 through the oil pipe 2, and the oil distributor 7 passes through the oil distribution pipe. 8 is connected with the lifting device 9, and the side of the lifting device 9 is connected with an expansion ring 10, and the outside of the expansion ring 10 is connected with a wall plate 6, and the outside of the wall plate 6 has a wall plate 5 to be welded.

[0020] Further, the lifting devices 9 are located on the upper periphery of the tower bottom plate 3 and are evenly distributed along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com