Elevator shaft operation platform

A technology for operating platforms and elevator shafts, which is applied in the direction of housing structure support, housing structure support, and scaffolding supported by housing structures, etc. problems, to improve the stability and safety of use, improve the construction environment, and achieve the effect of reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with embodiment.

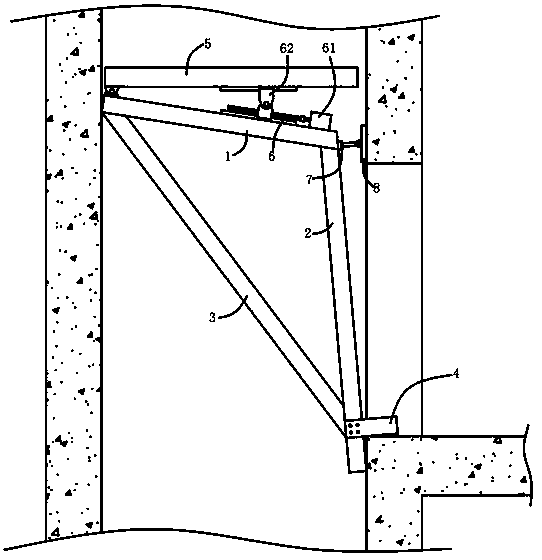

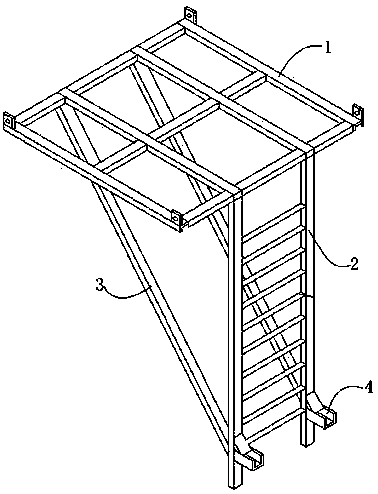

[0028] During specific implementation: if figure 1 As shown, an elevator shaft operating platform is supplemented with the structure of the existing elevator shaft operating platform for ease of understanding, such as figure 2 As shown, it includes a top frame 1 arranged horizontally and in a rectangular shape as a whole, a support frame 2 vertically arranged is fixedly installed on one side of the top frame 1, and a diagonal brace is fixedly installed between the top frame 1 and the support frame 2 3, the lower end of the brace 3 is connected to the lower end of the support frame 2, and the upper end is connected to the side of the top frame 1 away from the support frame 2; the position of the support frame 2 near the bottom has a The corbel 4 vertically arranged in the direction away from the diagonal brace 3, the top frame 1 is also provided with lifting lugs for lifti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com