Elastic base plate of railway concrete sleeper bottom

An elastic backing plate and concrete technology, which is applied in the field of rail transit, can solve the problems of small lateral resistance of the ballast bed, poor bonding effect, and high bonding cost, and achieve the effects of overcoming the lateral resistance of the ballast bed, quick and convenient installation, and improving the degree of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

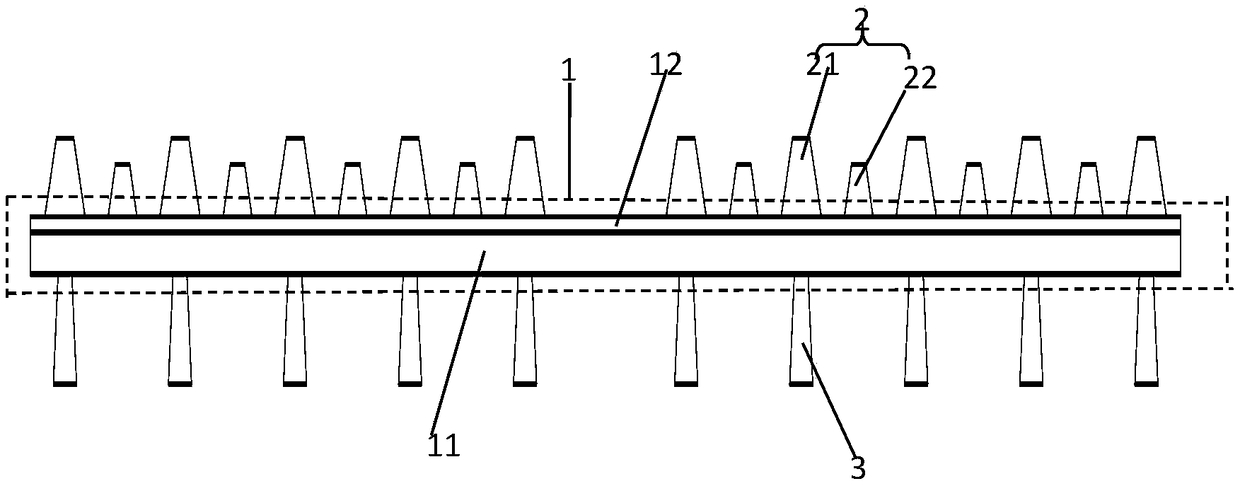

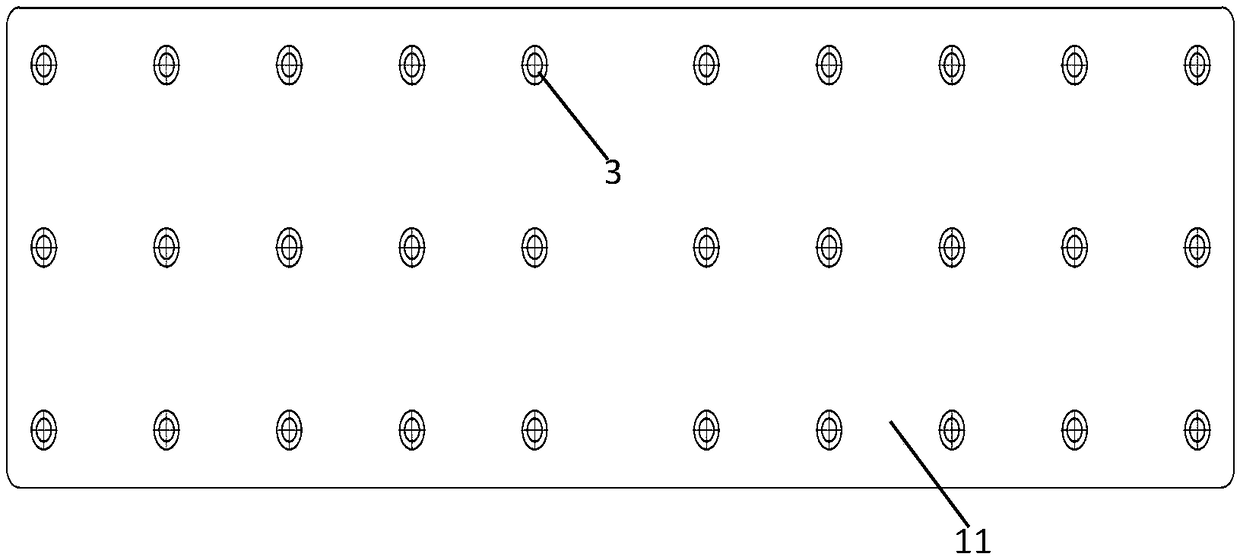

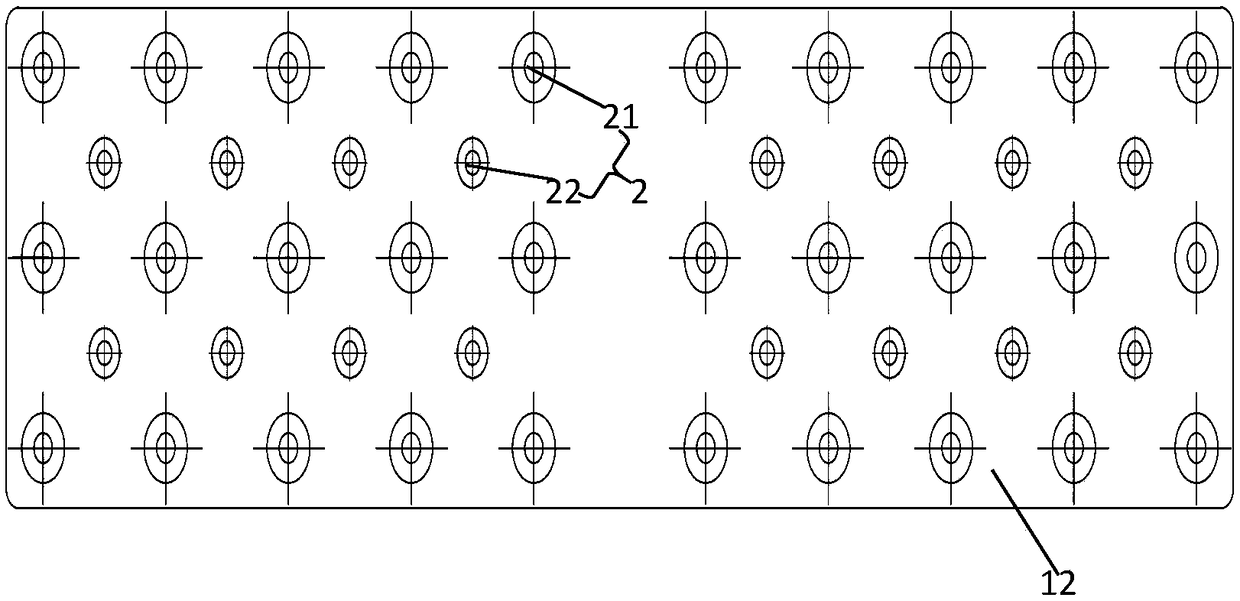

[0046] Embodiment 1 of the present invention provides an elastic backing plate at the bottom of a railway concrete sleeper, which is arranged between the bottom of the concrete sleeper and the ballast, and includes a raised structure 2, a rivet structure 3, an elastic layer 11 and a protective layer 12, and the raised structure 2 , rivet structure 3, elastic layer 11 and protective layer 12 integrally connected, elastic layer 11 adopts rubber, polyurethane or other similar materials to make, can be microporous foam structure also can be solid structure, its main function is to provide appropriate Elasticity, so as to effectively reduce the damage rate of the ballast bed, the material of the protective layer 12 includes rubber, polyurethane, blended cord fabric, polyester and non-woven fabric, so that the elastic layer 11 is protected from being damaged by the ballast under the operation load through the protective layer 12 , and the elastic layer 11 and the protective layer 12 ...

Embodiment 2

[0048] Embodiment 2 of the present invention provides an elastic backing plate for the bottom of a railway concrete sleeper, which is arranged between the bottom of the concrete sleeper and the ballast, and includes a raised structure 2, a rivet structure 3, an elastic layer 11, a protective layer 12 and a connecting layer 13, and The protruding structure 2, the rivet structure 3, the elastic layer 11, the protective layer 12 and the connection layer 13 are integrally connected. The elastic layer 11 is made of rubber, polyurethane or other similar materials, and can be a microporous foam structure or a solid structure. Its main function is to provide appropriate elasticity, thereby effectively reducing the damage rate of the ballast bed. The material of the protective layer 12 includes rubber, polyurethane, blended cord fabric, polyester and non-woven fabric, so that the elastic layer 11 can be protected by the protective layer 12 during operation. It will not be damaged by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com