Label glue spraying device for beer labeling machine

A labeling machine and glue spraying technology, applied in the field of label glue spraying device of beer labeling machine, can solve the problems affecting the appearance of outer packaging, bubbling wrinkles, label bubbling wrinkles and the like, achieve simple structure, avoid waste, Fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

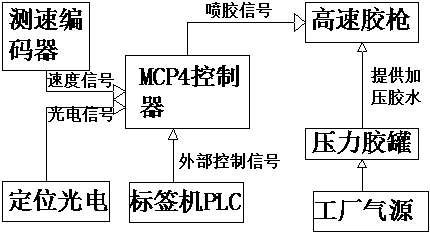

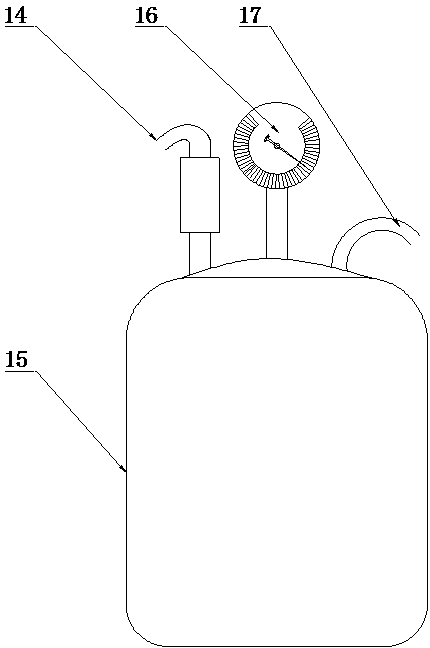

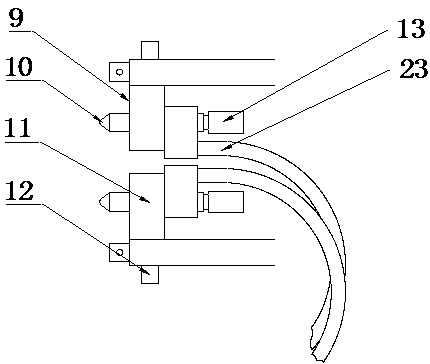

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The shown one is used for label spraying device of beer labeling machine, including motor 5, rotating shaft 6, target plate fixing rod 2, mark taking plate 4 and control device 22, and one end of rotating shaft 6 is provided with speed measuring encoder 3 , the speed measuring encoder 3 is connected with the control device 22, the other end of the rotating shaft 6 is provided with a motor 5, the rotating shaft 6 is coaxially arranged with the motor 5, the surface of the rotating shaft 6 is provided with a laser receiver 8, and the surrounding of the rotating shaft 6 is arranged There is a target plate fixing rod 2 for fixing the target plate 4, and the two ends of the target plate 4 are provided with a target plate groove 7 for conveniently clamping the label on the target plate 4, and the left side of the target plate fixing rod 2 is set There is a laser transmitter 1 for emitting laser ...

Embodiment 2

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a label spraying device for a beer labeling machine is provided with a speed measuring encoder 3 at one end of the rotating shaft 6, the speed measuring encoder 3 is connected with the control device 22, and the other end of the rotating shaft 6 is provided with a motor 5, The rotating shaft 6 is coaxially arranged with the motor 5, the surface of the rotating shaft 6 is provided with a laser receiver 8, and the surrounding of the rotating shaft 6 is arranged with a target plate fixing rod 2 for fixing the target plate 4, and the two ends of the target plate 4 are arranged There is a marking plate groove 7 for conveniently clamping the label on the marking plate 4, the left side of the marking plate fixing rod 2 is provided with a laser emitter 1 for emitting laser light to the laser receiver 8, and the side end of the marking plate 4 is A high-speed glue gun 9 is provided, and ...

Embodiment 3

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a label spraying device for a beer labeling machine is provided with a speed measuring encoder 3 at one end of the rotating shaft 6, the speed measuring encoder 3 is connected with the control device 22, and the other end of the rotating shaft 6 is provided with a motor 5, The rotating shaft 6 is coaxially arranged with the motor 5, the surface of the rotating shaft 6 is provided with a laser receiver 8, and the surrounding of the rotating shaft 6 is arranged with a target plate fixing rod 2 for fixing the target plate 4, and the two ends of the target plate 4 are arranged There is a marking plate groove 7 for conveniently clamping the label on the marking plate 4, the left side of the marking plate fixing rod 2 is provided with a laser emitter 1 for emitting laser light to the laser receiver 8, and the side end of the marking plate 4 is A high-speed glue gun 9 is provided, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com