Flexible towline cable

A drag chain cable, flexible technology, applied in the direction of insulated cables, bendable cables, flat/ribbon cables, etc., can solve the problems of shortening cable life, cable outlet kinks, unfavorable cable installation, etc., to achieve good bending resistance. , Uniform force, the effect of solving the problem of easy disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

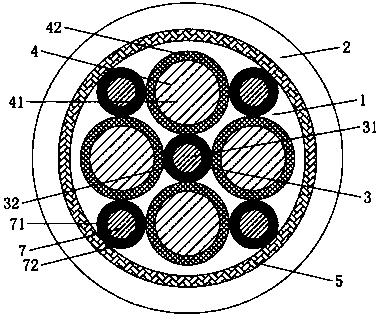

[0015] A flexible towline cable of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 with figure 2 As shown, a flexible towline cable includes: a plurality of wires with coplanar axes, the same outer diameter and closely arranged side by side, a plurality of ribbon-shaped connectors 9 connected between the wires, each ribbon-shaped connector 9 forms a telescoping cavity between the two wires connected to it, and an adhesive that is arranged to connect the wires in the telescoping cavity; the conductor 8 includes a cable core 1, a non-woven wrapping cloth 5 on the outside of the core, and The sheath 2 outside the non-woven fabric wrapping cloth 5; the wire core includes a tensile wire body 3, four sets of core wires 4 arranged outside the tensile wire body 3, and tensile wires arranged between adjacent core wires 4. Wire body 3; the core wire 4 includes a core wire wire 41 and a core wire insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com