Online measuring device for outer arc arc-alignment precision of continuous casting machine

A technology of measuring device and continuous casting machine, applied in the direction of measuring device, instrument, etc., can solve the problem that the sector segment is not good for the arc and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

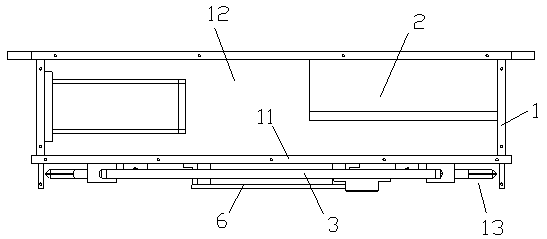

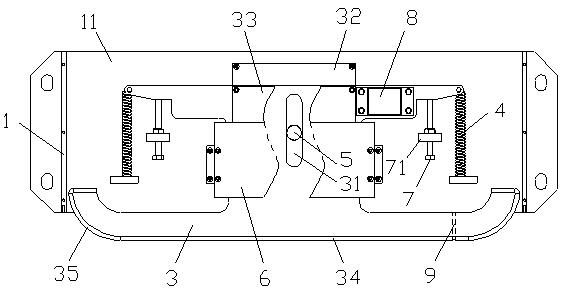

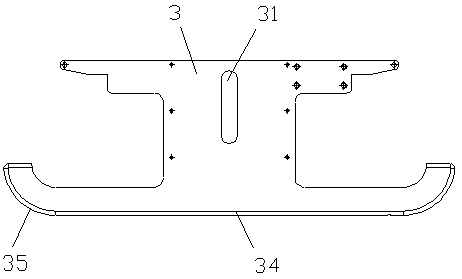

[0016] Example figure 1 , figure 2 and image 3 As shown, the online measuring device for the accuracy of the arc alignment of the outer arc of the continuous casting machine of the present invention includes a housing 1, a control module 2, an arc alignment plate 3, a spring 4, a roller 5, a baffle plate 6, an adjustment bolt 7, an inclination sensor 8 and a proximity Switch 9, the housing 1 is divided into a closed rear chamber 12 and an open front chamber 13 by a partition 11, the control module 2 is arranged in the rear chamber 12, and the baffle 6 Located in the front chamber 13 and set on the partition 11 by bolts, the arc counter plate 3 is I-shaped and the middle part is located between the baffle 6 and the partition 11, the spring 4 is located in the The two sides of the anti-arc plate 3 and the two ends of the spring 4 are respectively connected to the partition plate 11 and the two sides of the rear end surface of the anti-arc plate 3. The middle part of the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com